Oxygen removing method of butadiene refining device

A refining device and butadiene technology, applied in chemical instruments and methods, purification/separation of hydrocarbons, hydrocarbons, etc., can solve problems such as equipment blockage, achieve the effect of reducing butadiene loss and prolonging the operating cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

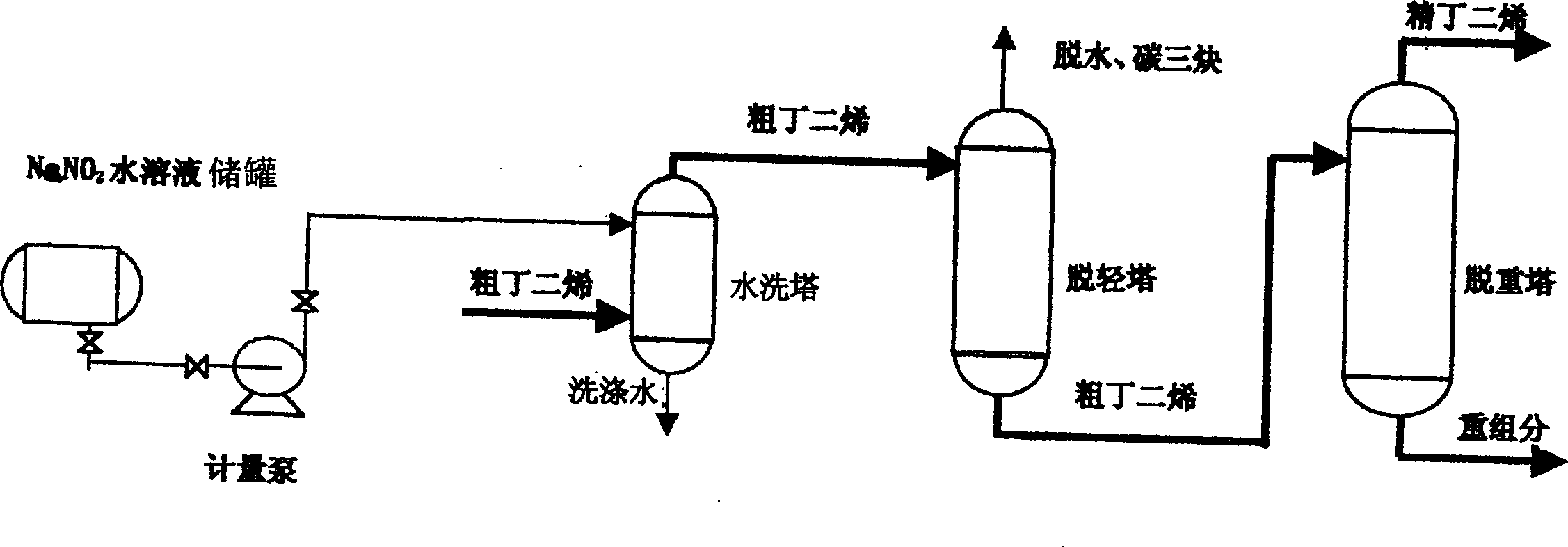

[0014] The raw material crude butadiene enters the water washing tower to remove oxygen-containing compounds such as acetonitrile, dimers, aldehydes and ketones, and then removes carbon triyne and water through the light removal tower, and separates the heavy components through the weight removal tower, and finally obtains qualified polymer grade butadiene. According to the washing water of the washing tower, the medium and small amount of NaNO is produced 2 Analyze data and detect oxygen content in the system to control NaNO in produced water 2 When the concentration is below 10ppm, adjust the metering pump to output NaNO 2 Aqueous flow. The metering pump adopts electric or manual mode to adjust the flow rate and control NaNO 2 The concentration of the aqueous solution is 10-2000 ppm, preferably 20-300 ppm.

[0015] Such as: regularly prepare 40% NaNO in the storage tank 2 Aqueous solution, the oxygen content detected in the crude butadiene raw material is 3-7% (mass), a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com