On-line switchover method of multi-nozzle gasifier

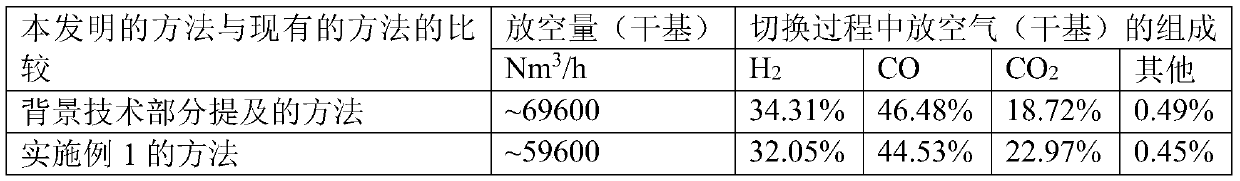

A gasification furnace and multi-nozzle technology, which is applied in the gasification of granular/powdered fuels, the manufacture of combustible gases, and the petroleum industry. It can solve problems such as fluctuations in the quality of syngas, large venting volume of syngas, and the impact on stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

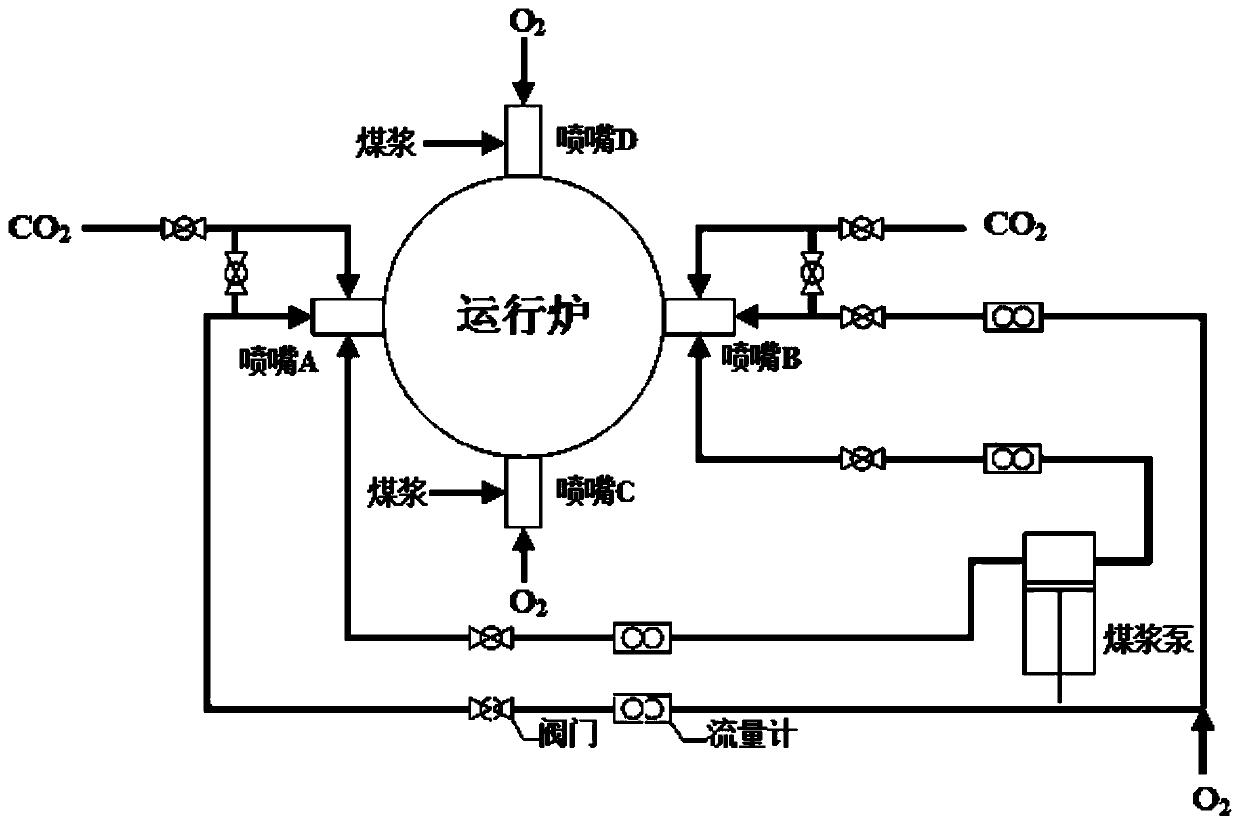

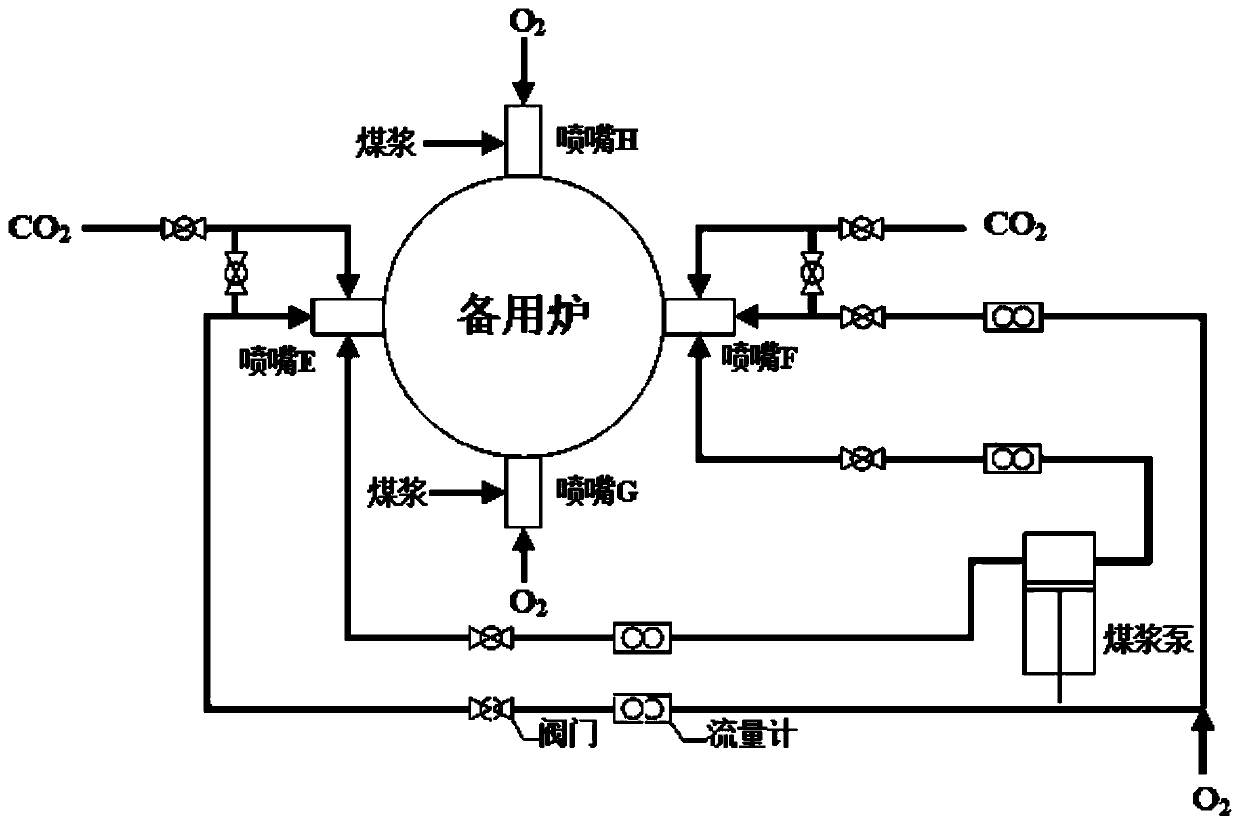

[0050] A method for online switching of a multi-nozzle gasifier, such as figure 1 and figure 2 As shown, the gasification furnace involved in the method includes an operating furnace and a standby furnace identical to the operating furnace; the operating furnace has four nozzles, and the nozzles are arranged in a horizontally opposed installation manner. The middle and upper part of the operating furnace, the nozzle is a three-channel annular casing structure with an outer channel, a middle channel and an inner channel. When the operating furnace is in normal operation, the middle channel is a coal slurry channel, and the outer channel And the inner channel is an oxygen channel; the method comprises the steps of:

[0051] (1) The oxygen in the inner channels of the four nozzles of the operating furnace is replaced by CO 2 , reducing the coal slurry flow rate of the middle channel of the four nozzles of the operating furnace to 85% of the normal operating flow rate;

[0052...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com