Patents

Literature

52results about How to "Reduce design margin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

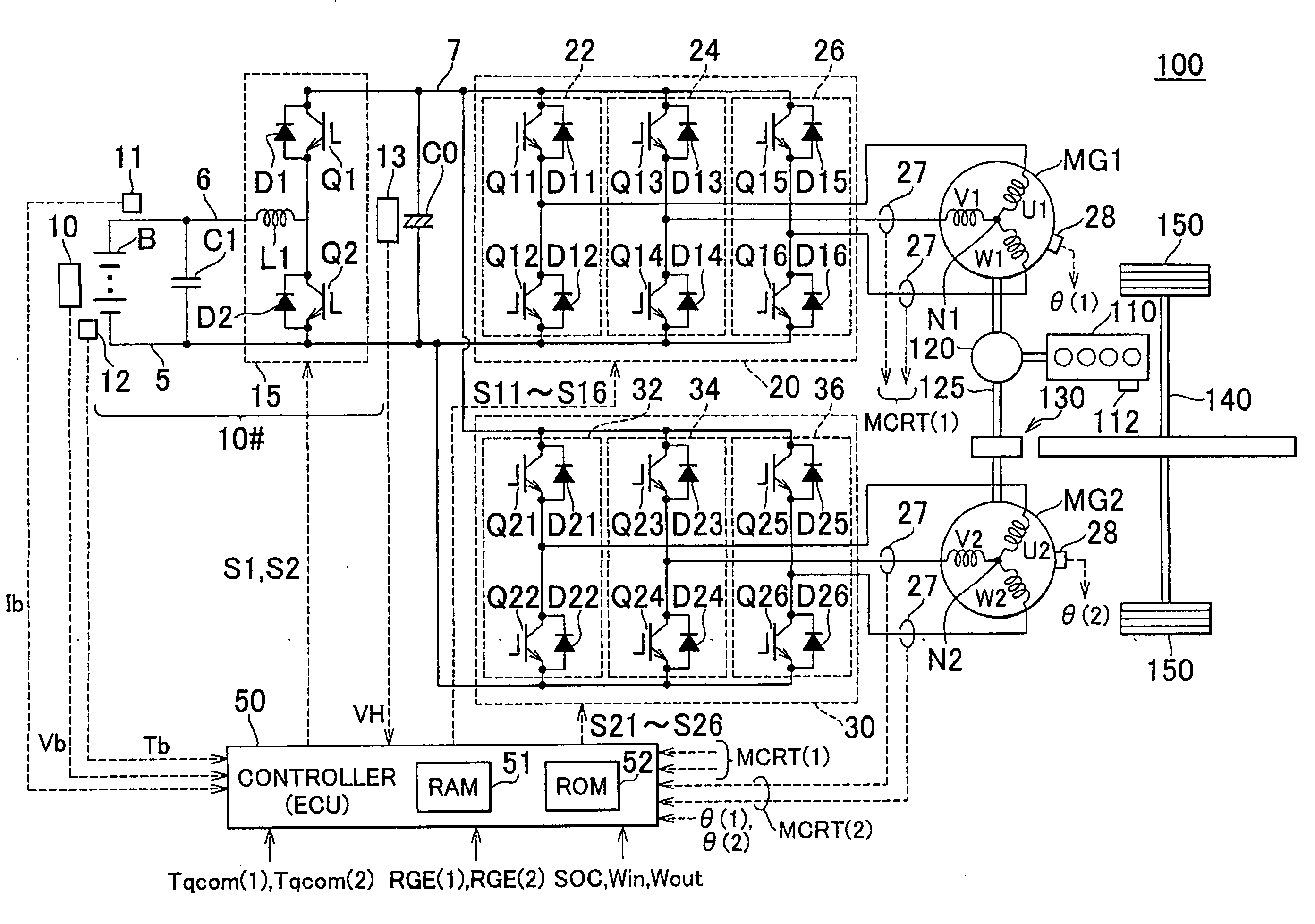

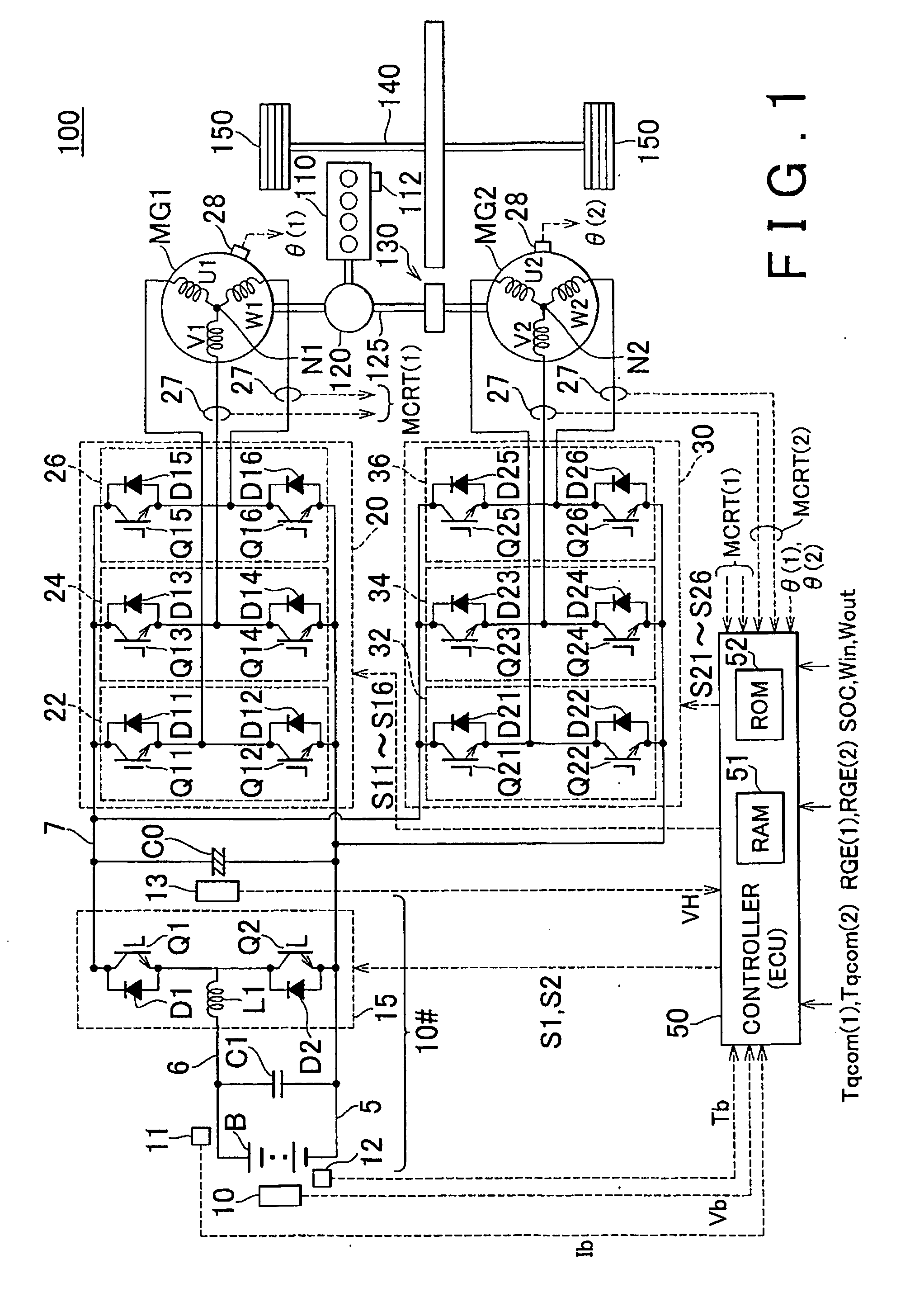

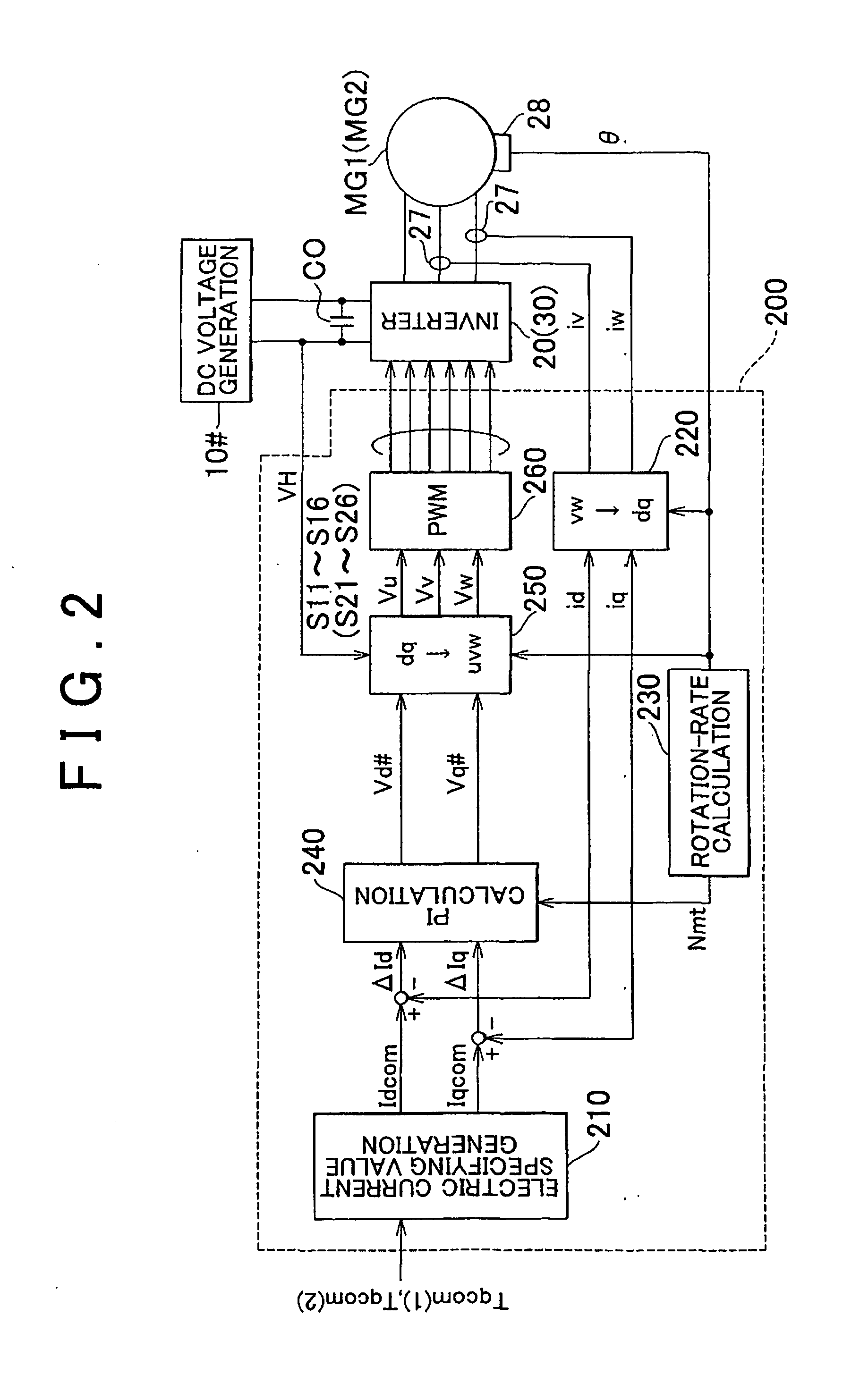

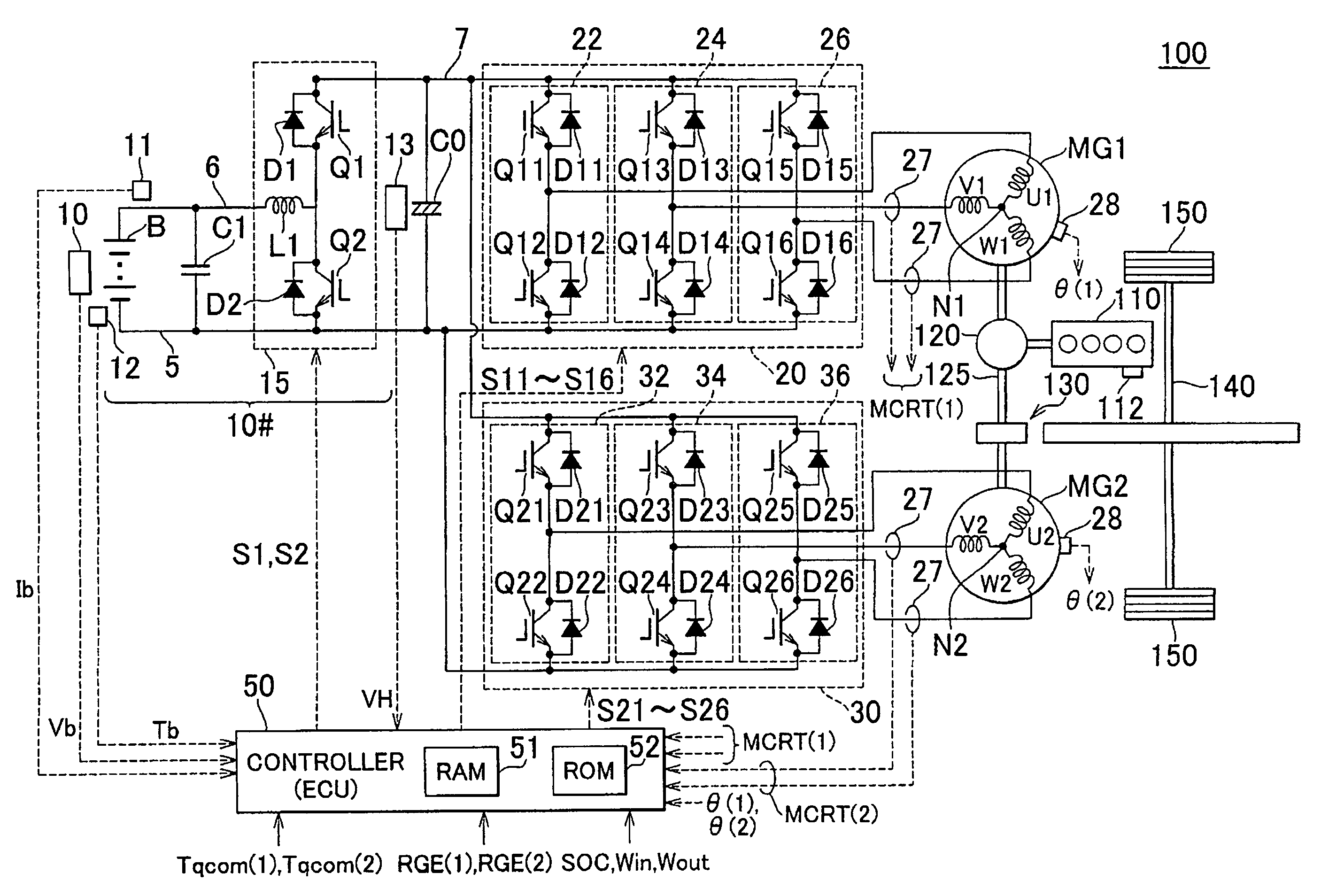

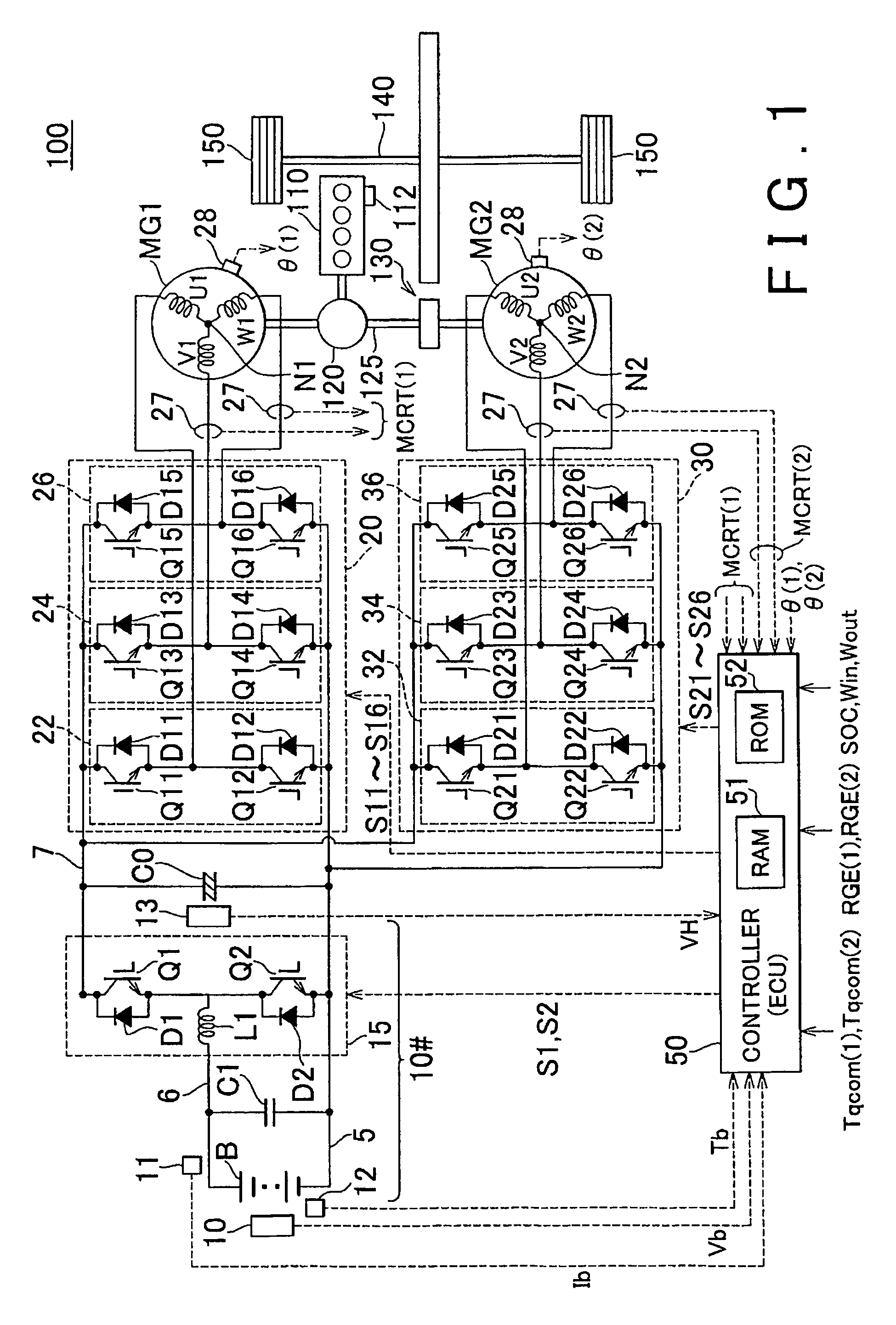

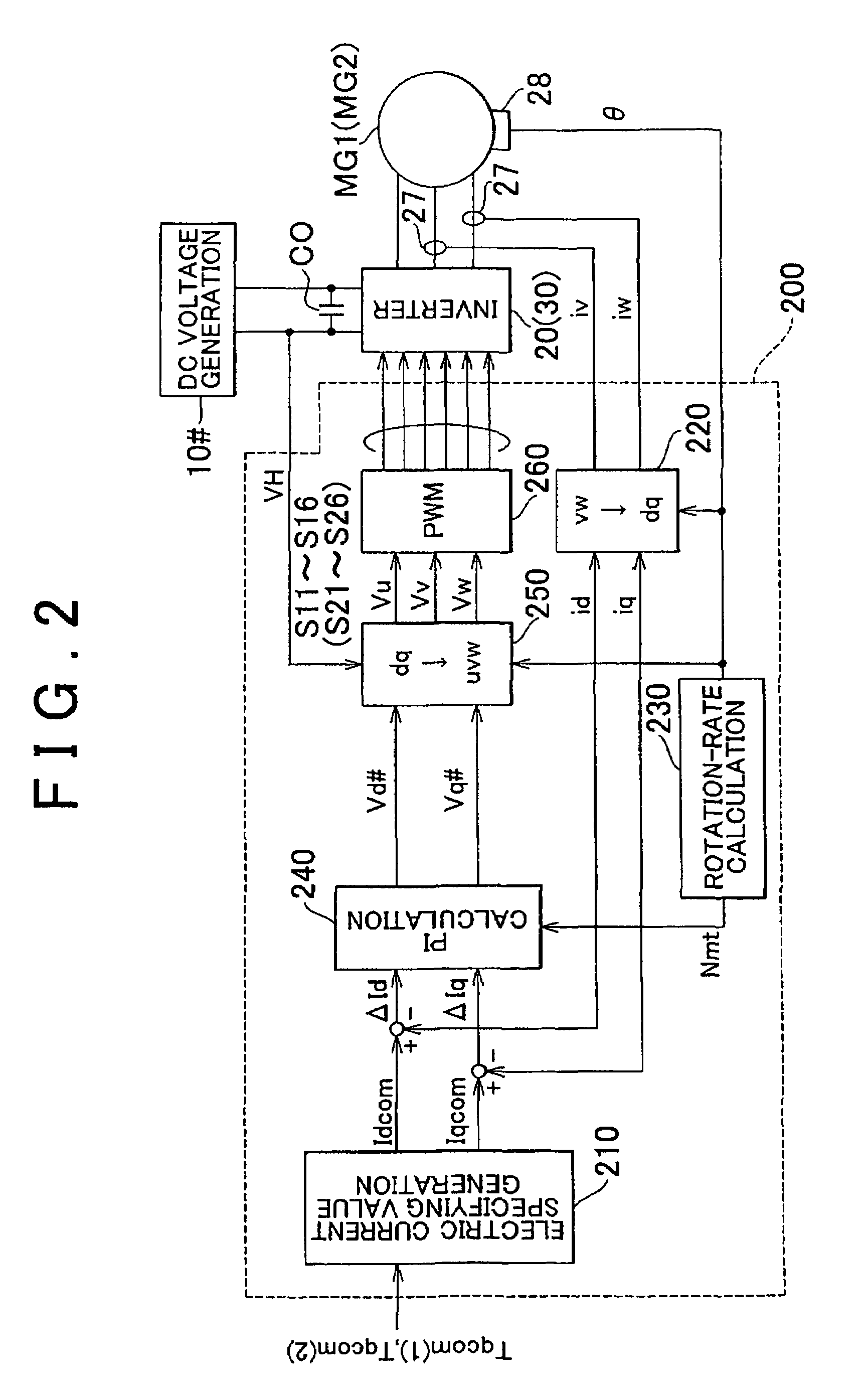

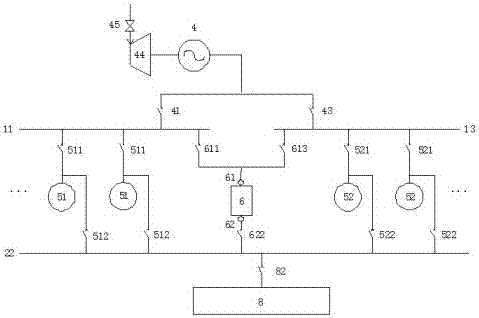

Internal combustion engine start controller

InactiveUS20070175429A1Reduce loadAvoid yield lossElectrical controlMuscle operated startersPower semiconductor deviceElectric power system

An internal combustion engine start controller in a vehicle that includes: a power source; an internal combustion engine that is started by using electric power supplied from the power source; a first motor; and a first electric power converter that is constructed so as to be able to perform electric power conversion between the power source and the first motor through switching control of power semiconductor elements is provided. The start controller includes: a start detecting device for detecting whether the engine is in a starting operation; and a first frequency setting device that, when the engine is in a starting operation, sets a switching frequency of the first electric power converter to a frequency lower than that used when the engine is not in a starting operation.

Owner:TOYOTA JIDOSHA KK

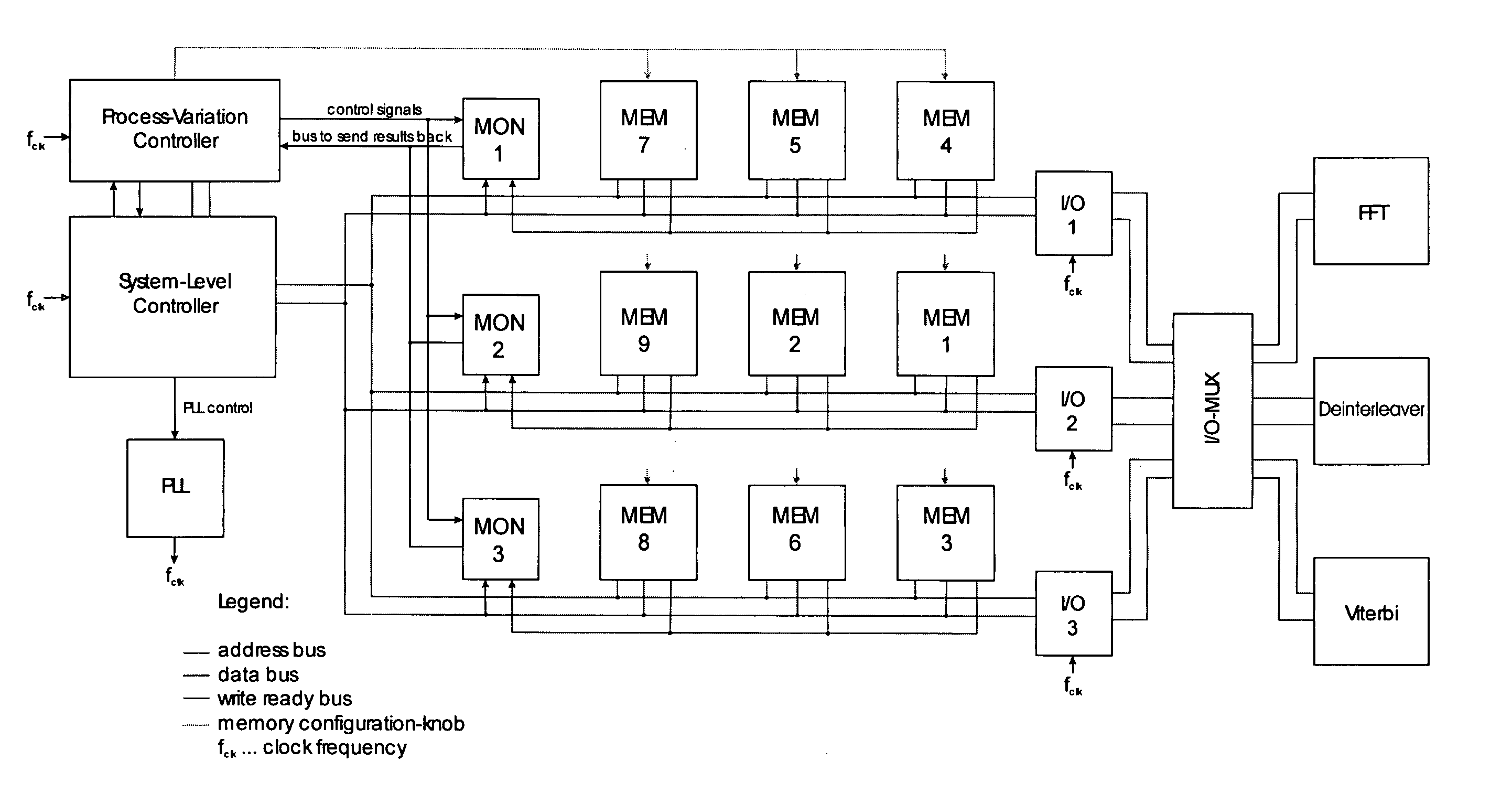

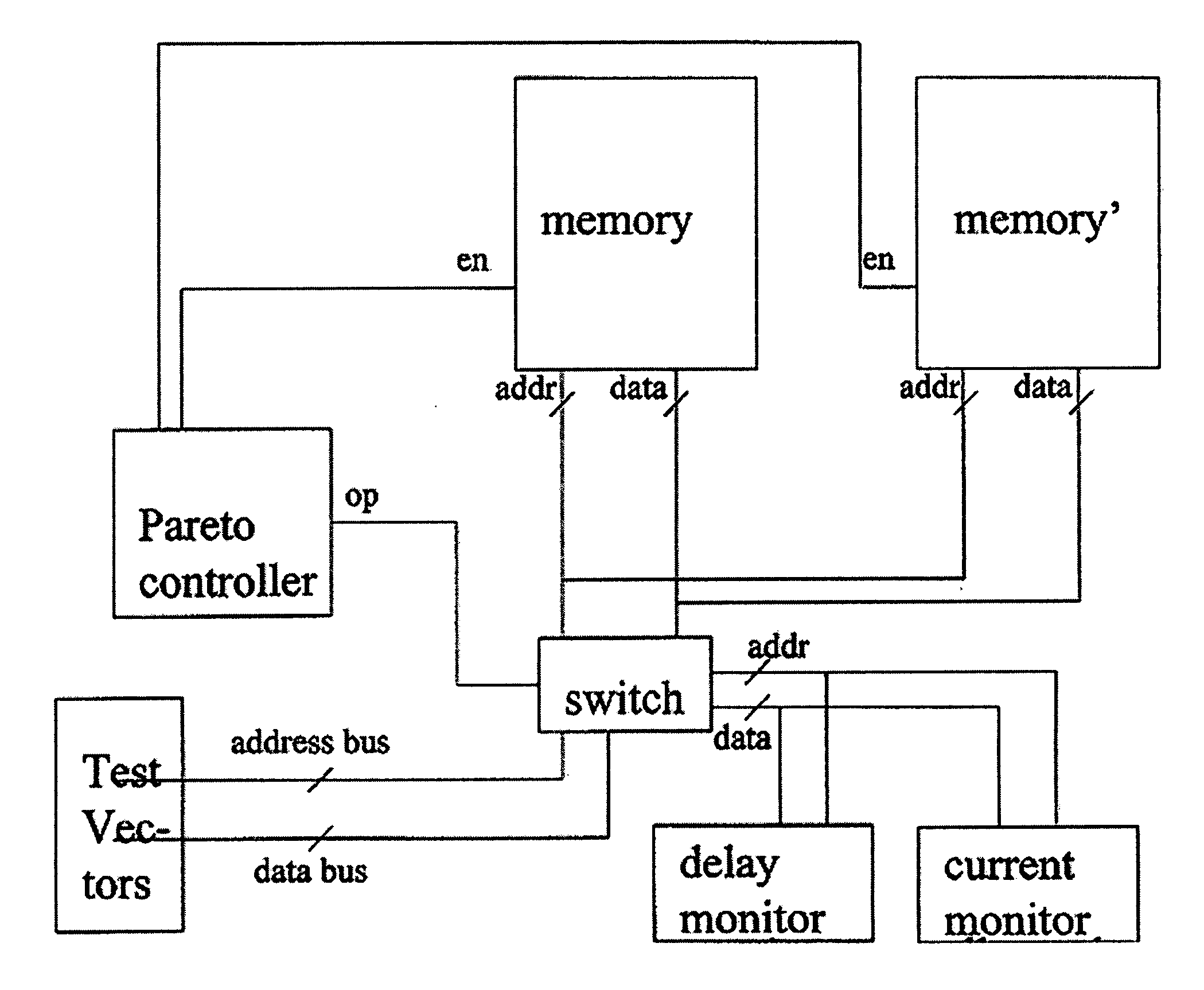

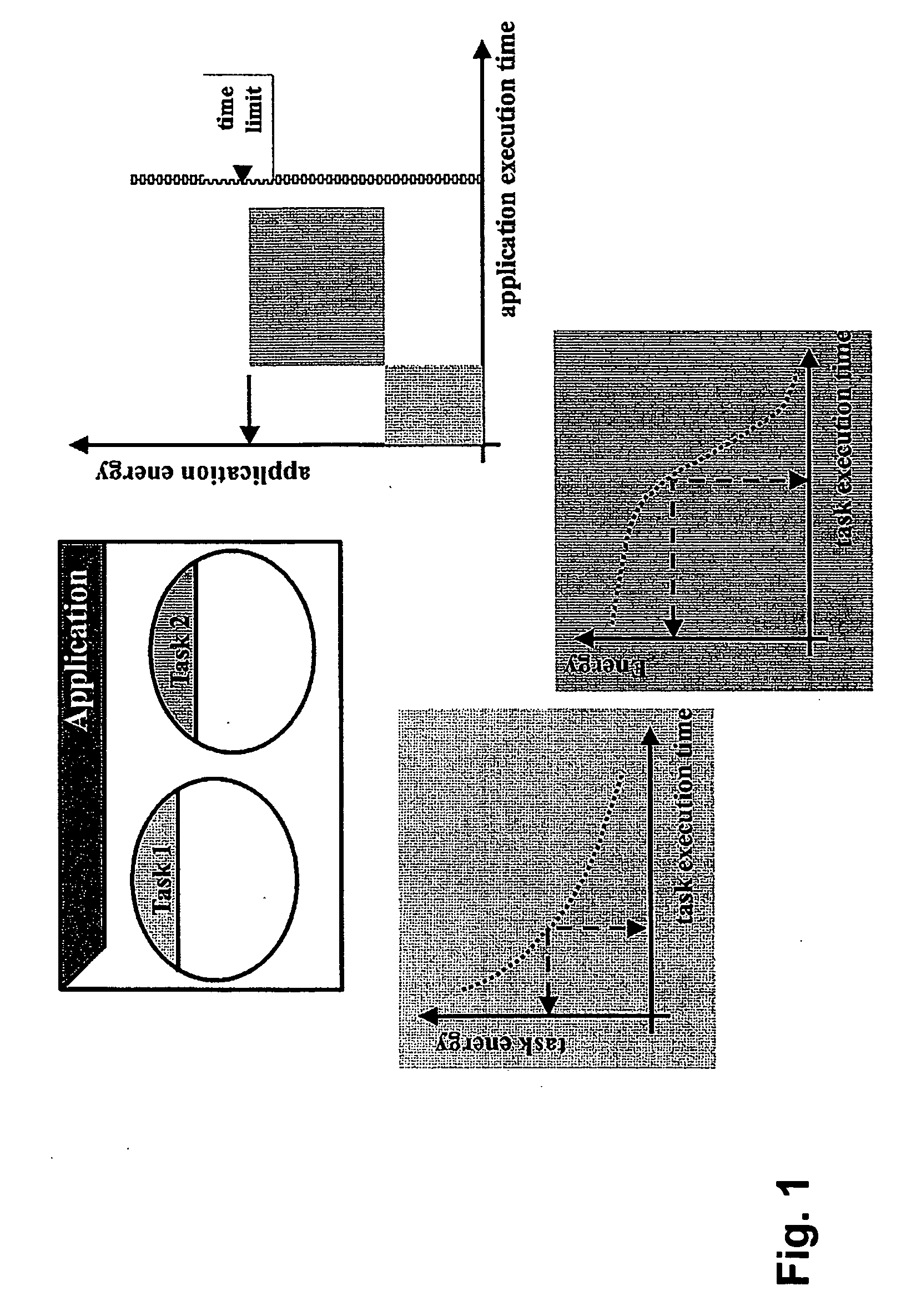

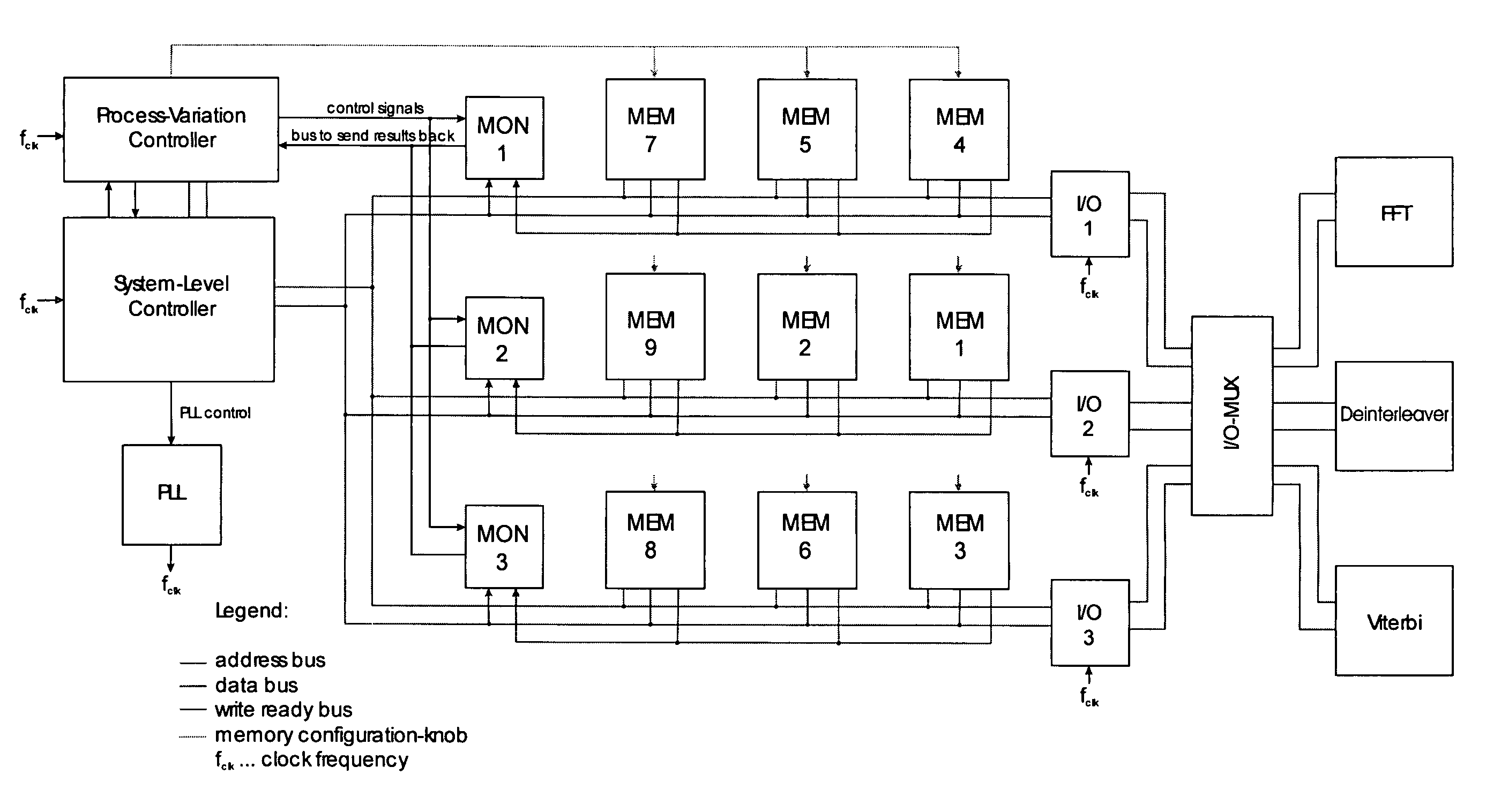

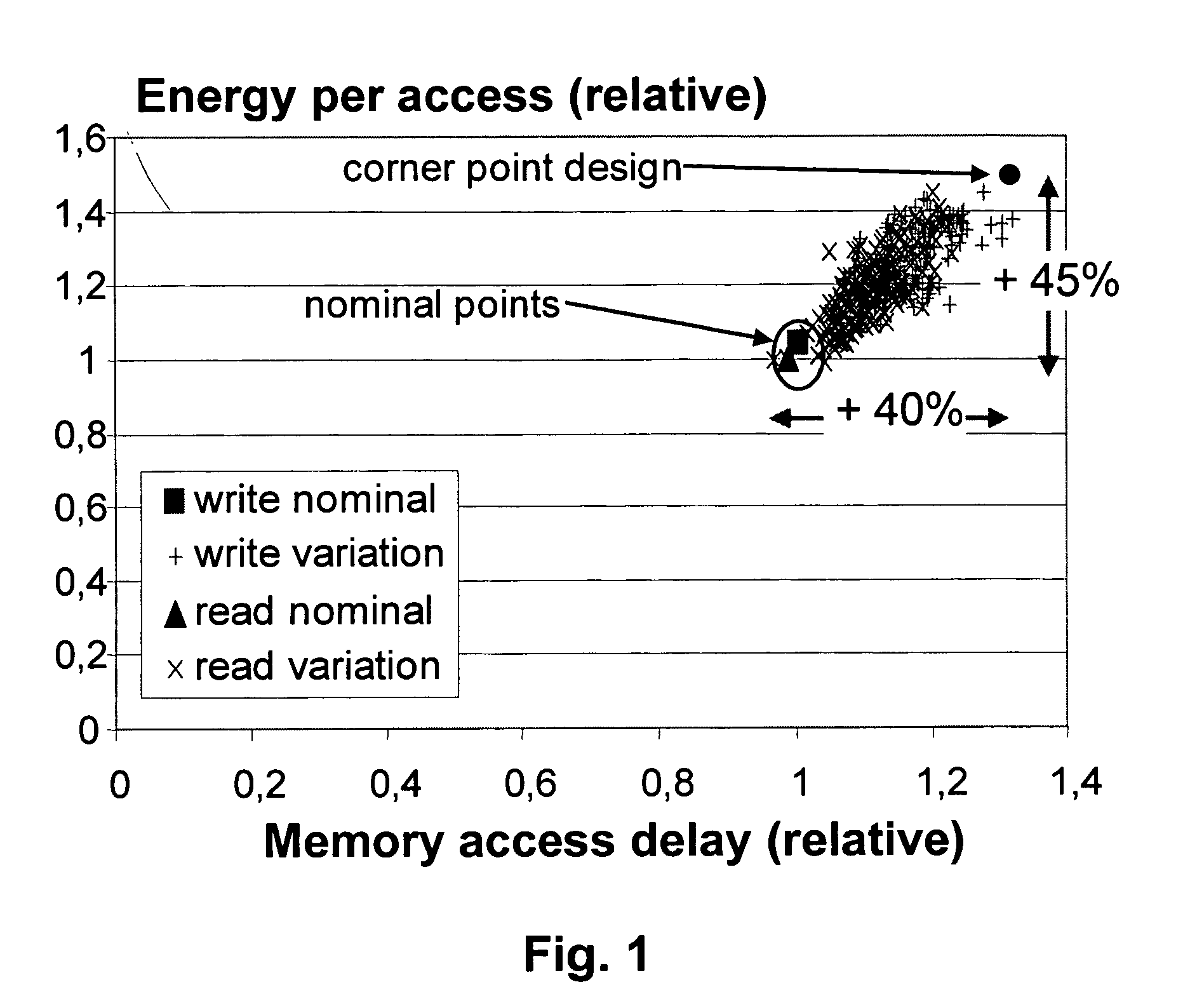

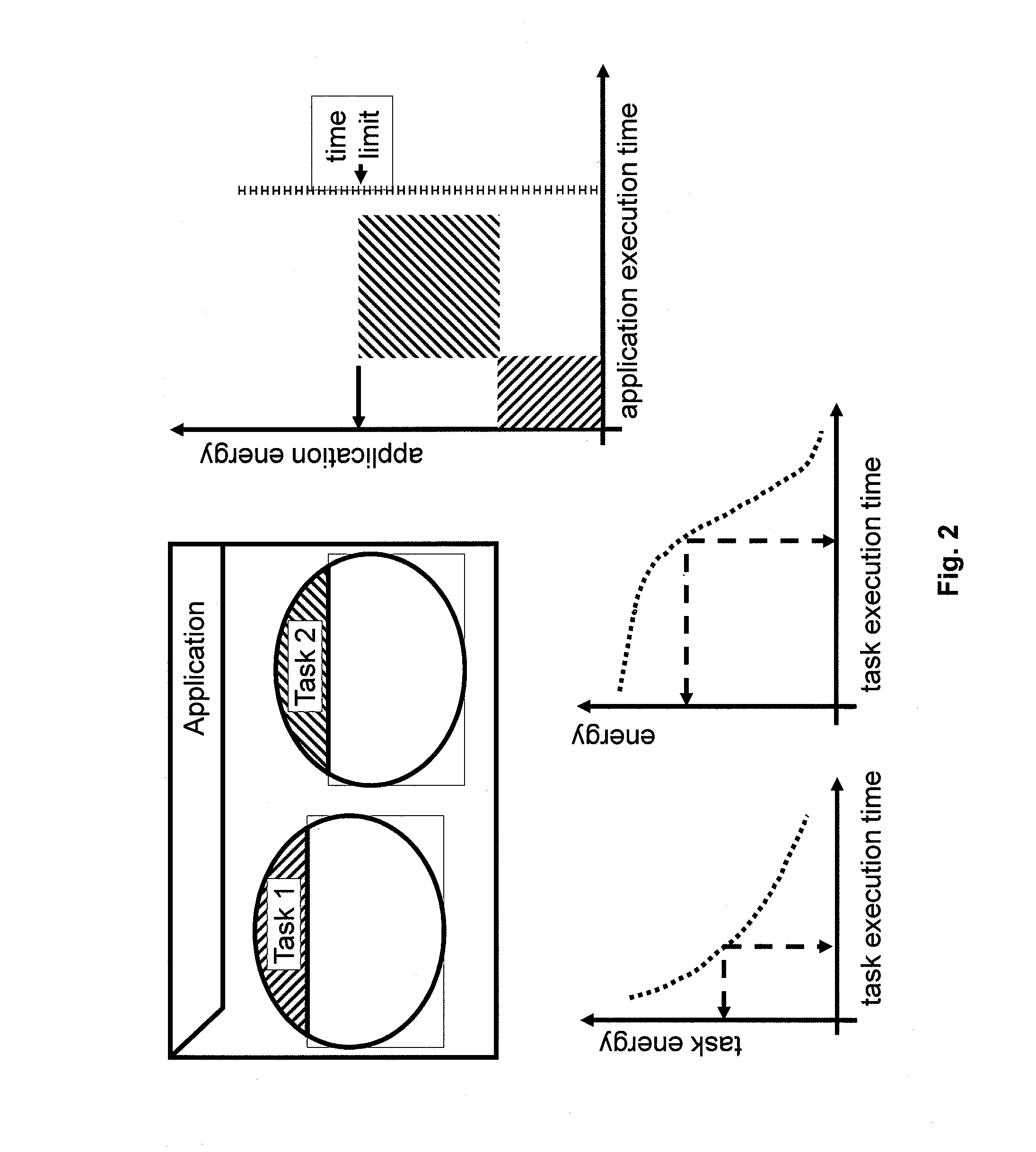

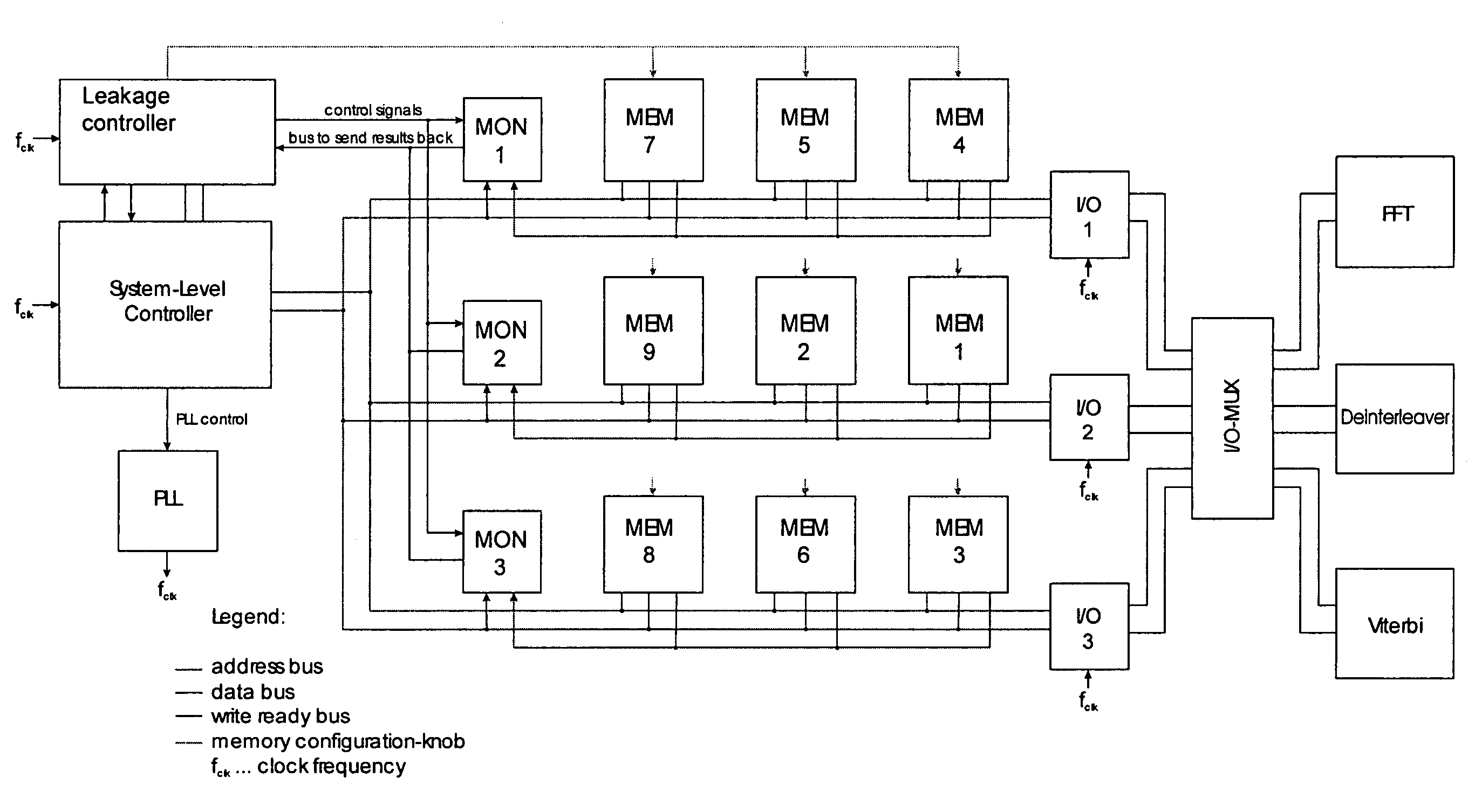

Method and apparatus for designing and manufacturing electronic circuits subject to process variations

ActiveUS20050235232A1Additional circuitryImprove the environmentDetecting faulty computer hardwareCAD circuit designDisplay deviceTrade offs

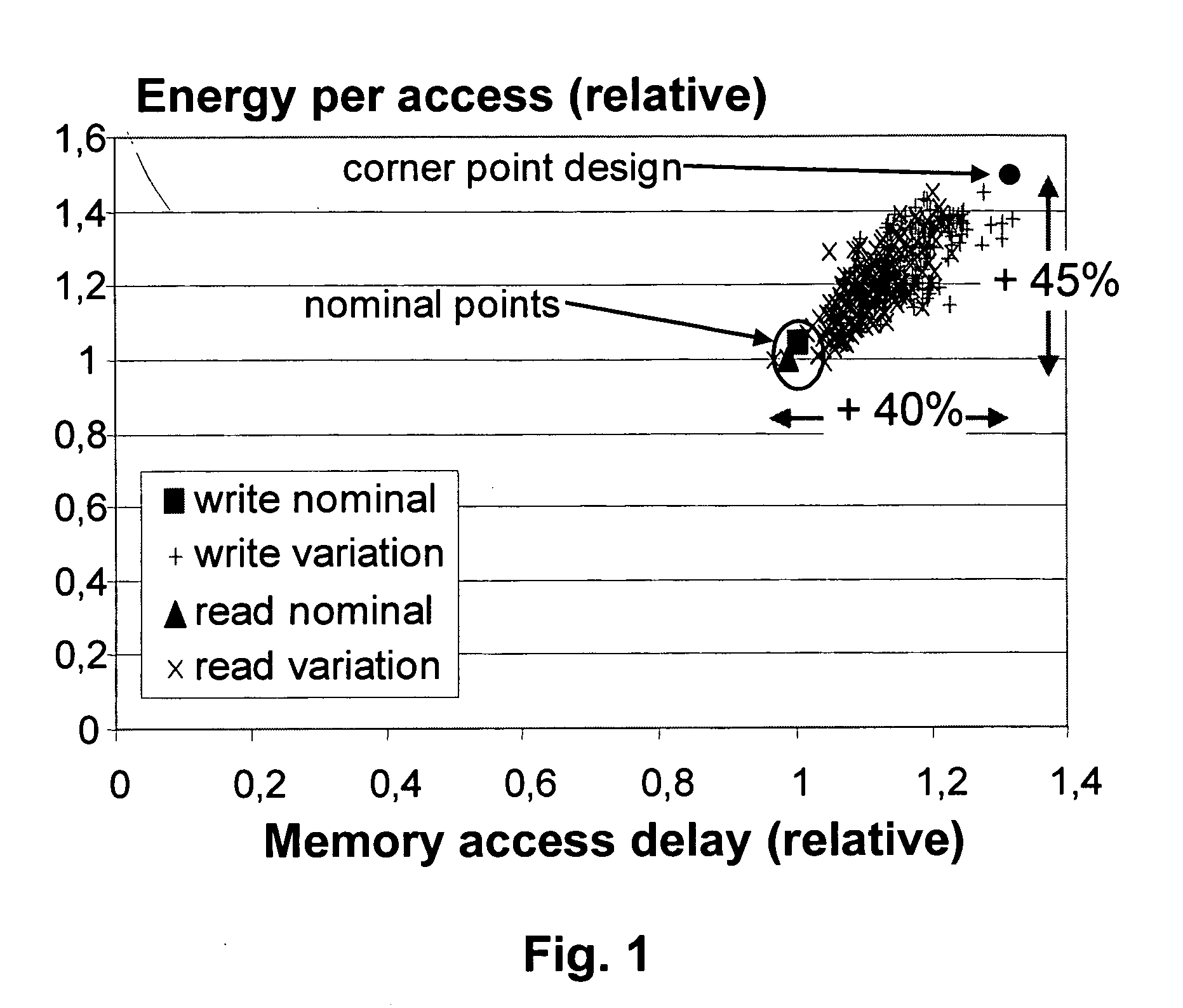

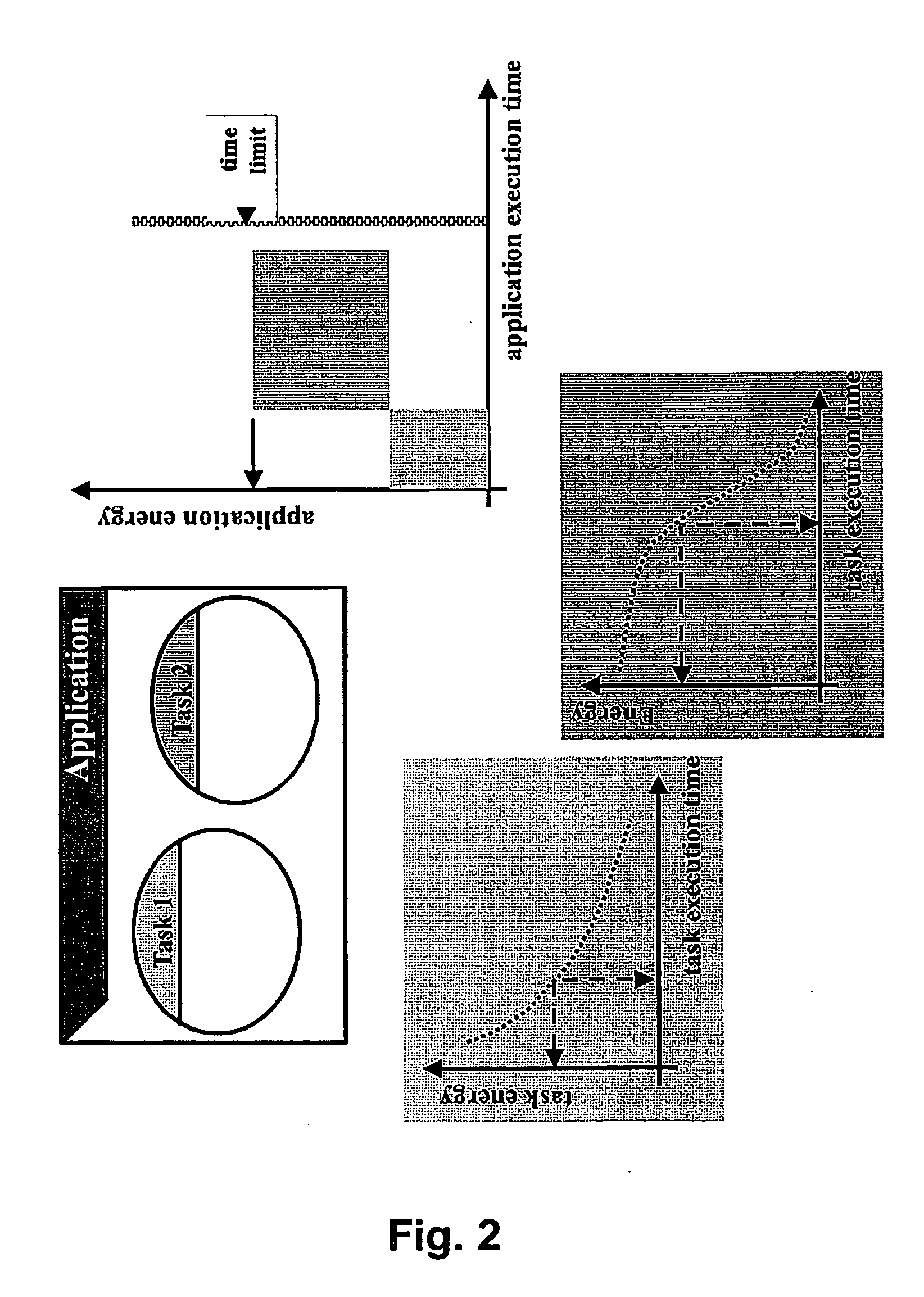

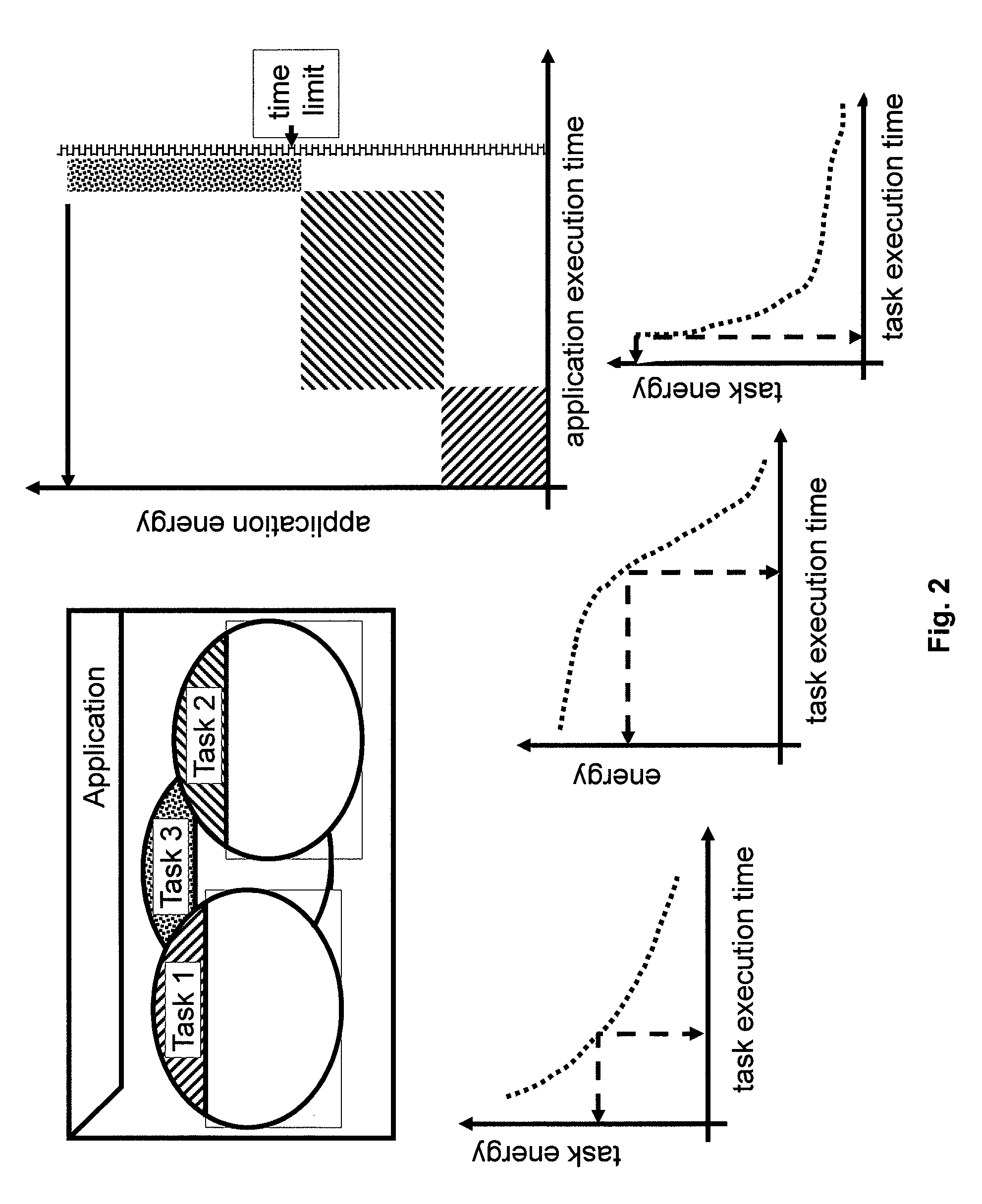

Methods and apparatus are described in which, at design-time a thorough analysis and exploration is performed to represent a multi-objective “optimal” trade-off point or points, e.g. on Pareto curves, for the relevant cost (C) and constraint criteria. More formally, the trade-off points may e.g. be positions on a hyper-surface in an N-dimensional Pareto search space. The axes represent the relevant cost (C), quality cost (Q) and restriction (R) criteria. Each of these working points is determined by positions for the system operation (determined during the design-time mapping) for a selected set of decision knobs (e.g. the way data are organized in a memory hierarchy). The C-Q-R values are determined based on design-time models that then have to be “average-case” values in order to avoid a too worst-case characterisation. At processing time, first a run-time BIST manager performs a functional correctness test, i.e. checks all the modules based on stored self-test sequences and “equivalence checker” hardware. All units that fail are deactivated (so that they cannot consume any power any more) and with a flag the run-time trade-off controllers, e.g. Pareto controllers, are informed that these units are not available any more for the calibration or the mapping. At processing time, also a set of representative working points are “triggered” by an on-chip trade-off calibration manager, e.g. a Pareto calibration manager, that controls a set of monitors which measure the actual C-Q-R values and that calibrates the working points to their actual values. Especially timing monitors require a careful design because correctly calibrated absolute time scales have to be monitored.

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW)

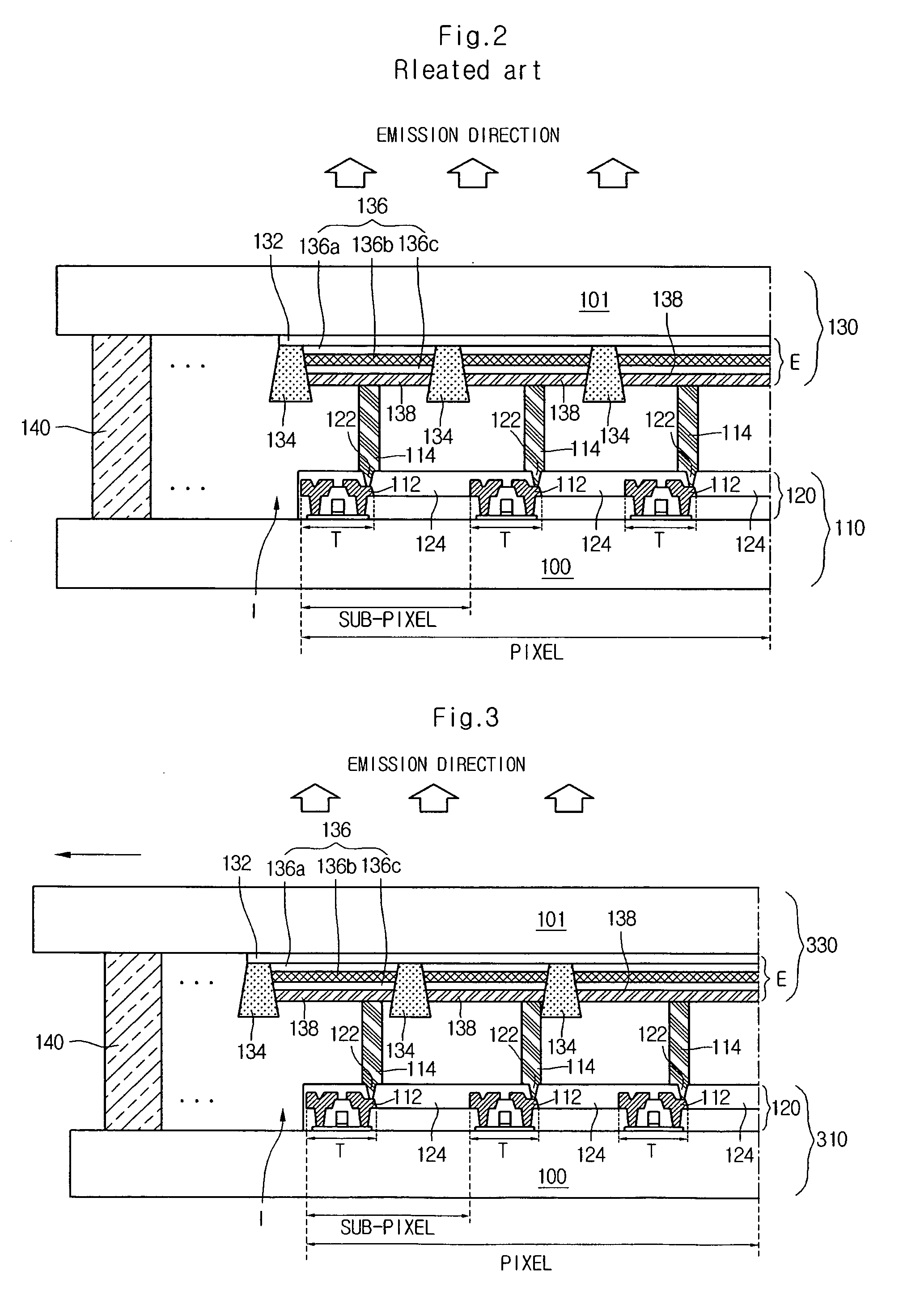

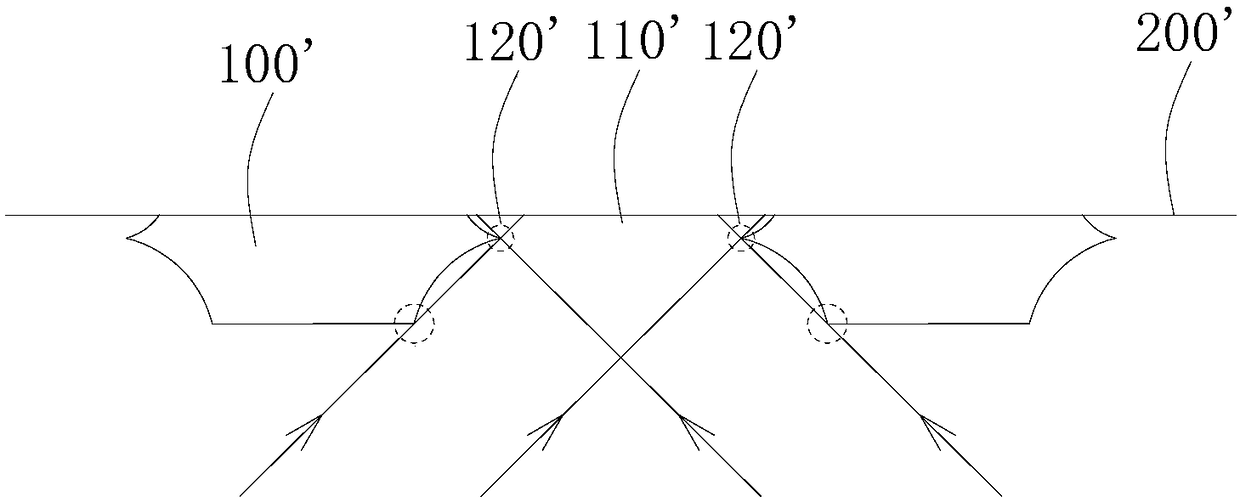

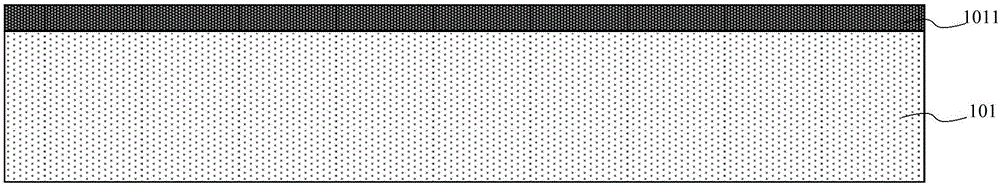

Organic electro-luminescence device and fabrication method thereof

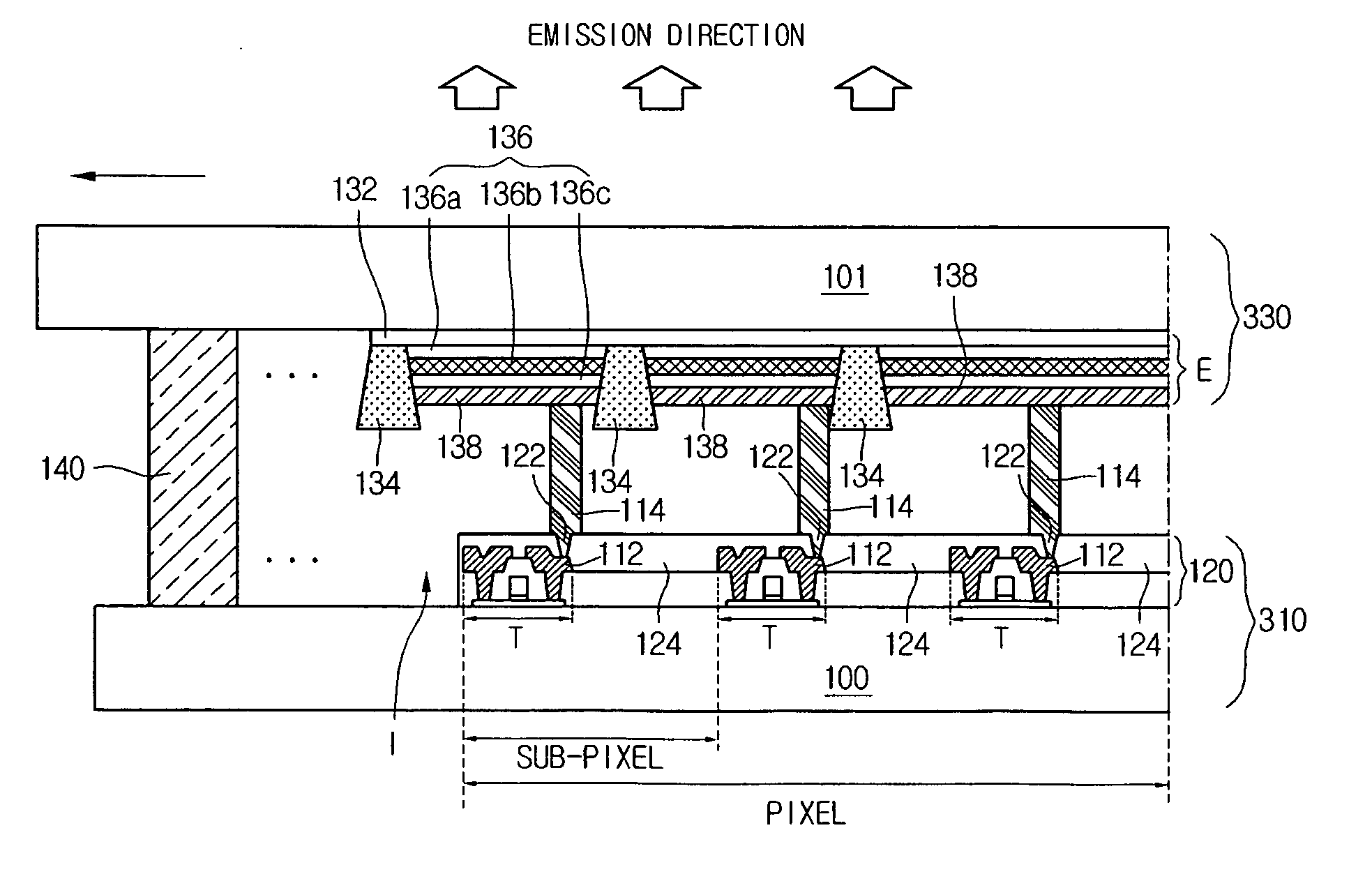

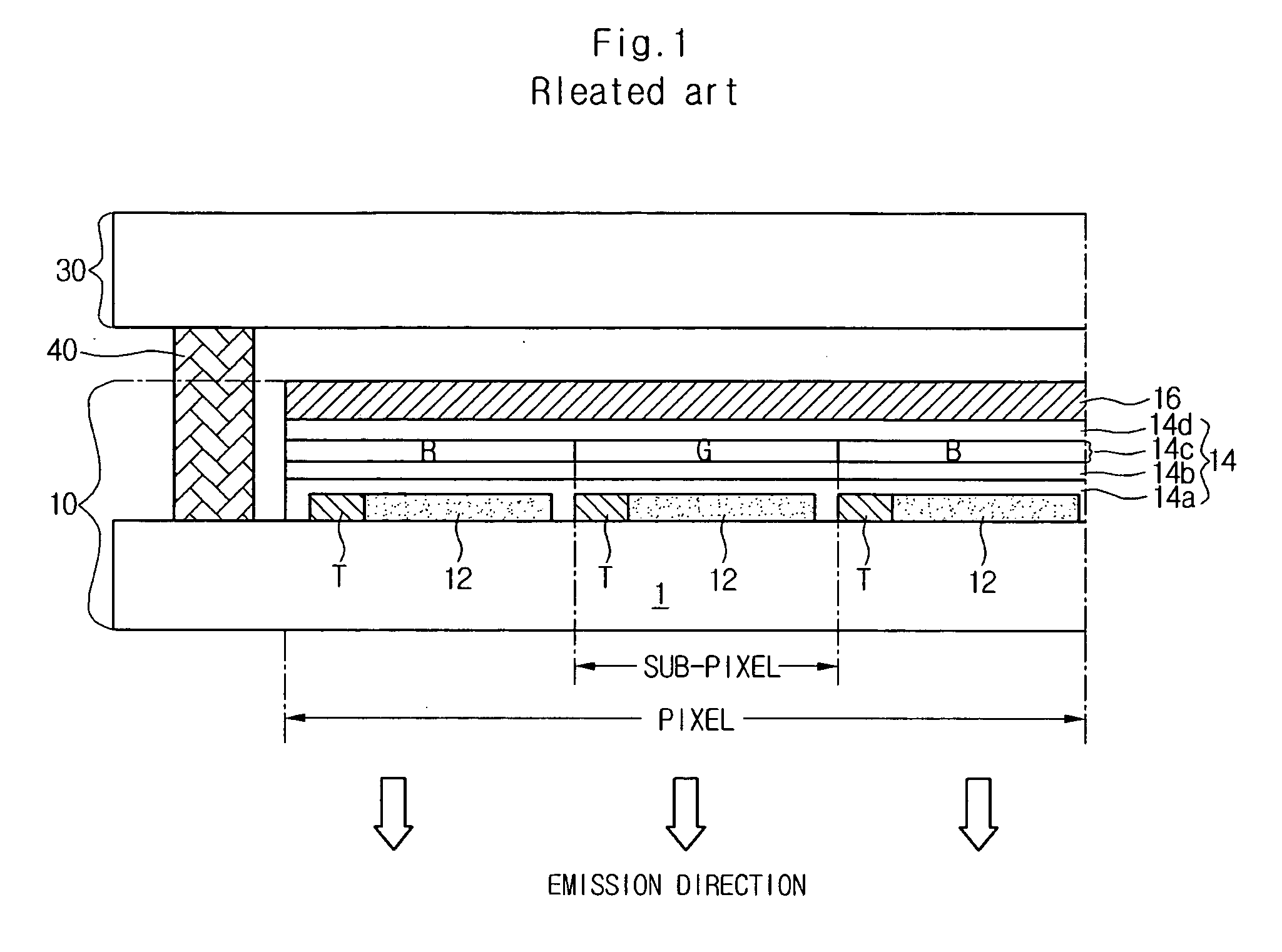

ActiveUS20050242717A1Reduce design marginDesign margin of the TFTs on the lower substrate can be reducedDischarge tube luminescnet screensElectroluminescent light sourcesArray elementOrganic electroluminescence

An organic electro-luminescence device is provided. First and second substrates are arranged spaced apart from each other by a predetermined distance and sub-pixels are defined in the substrates. An array element has at least one thin film transistor (TFT) formed on an inner surface of the first substrate in sub-pixel unit. A conductive spacer is electrically connected to a drive TFT of the array element. A first electrode for an organic electro-luminescence diode is disposed on an inner surface of the second substrate. An organic electro-luminescence layer and a second electrode for the organic electro-luminescence diode are sequentially formed on the first electrode in sub-pixel unit. The first substrate and the second substrate are misaligned by a predetermined position and attached to each other, such that the conductive spacer is in contact with a conductive spacer contact region provided on the second electrode.

Owner:LG DISPLAY CO LTD

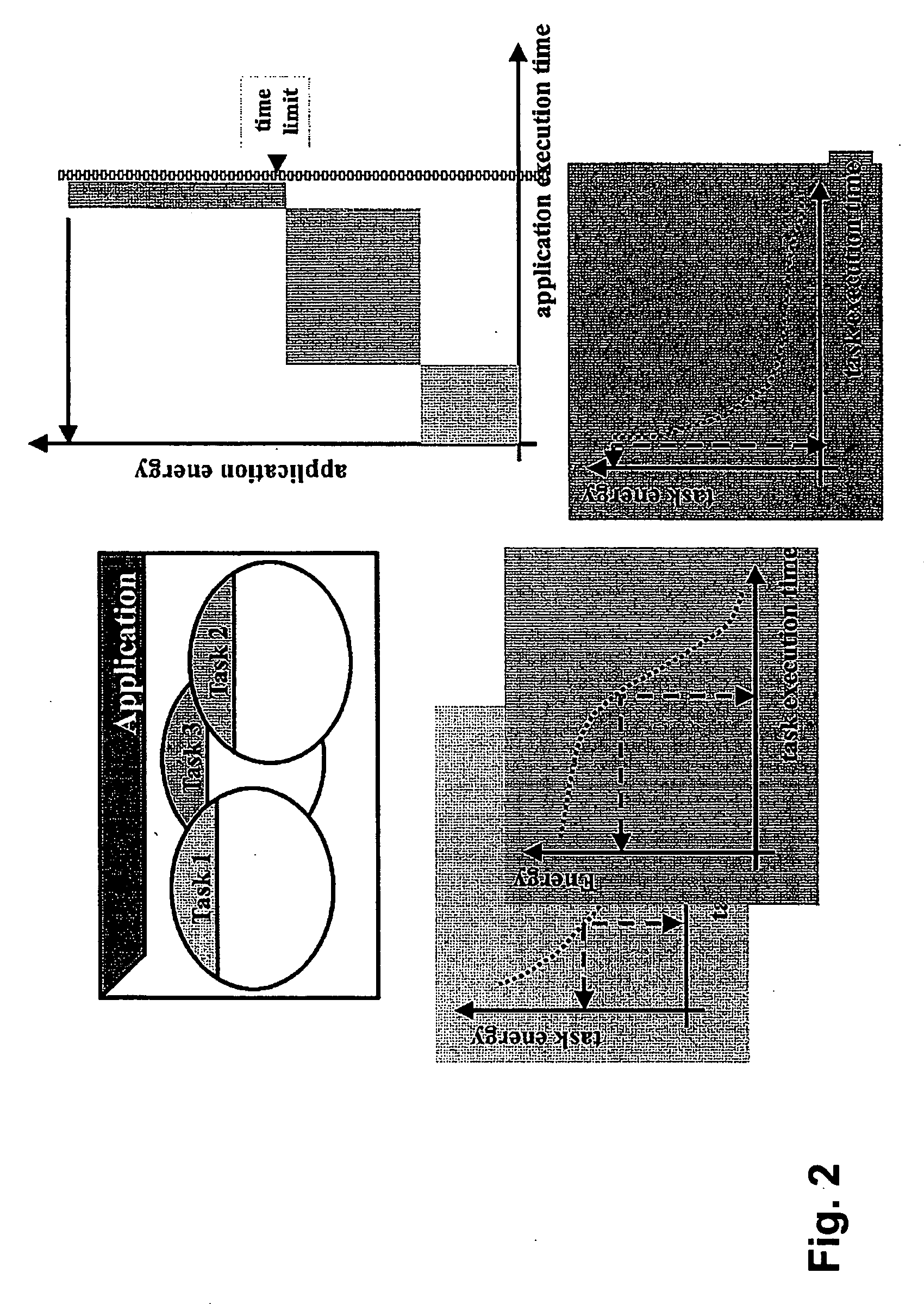

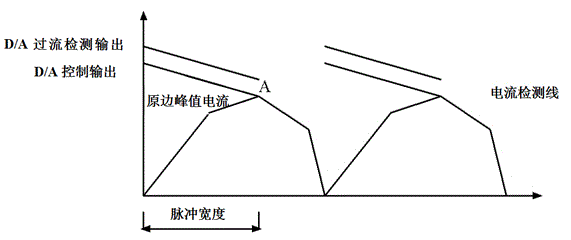

Method and apparatus for designing and manufacturing electronic circuits subject to leakage problems caused by temperature variations and/or ageing

ActiveUS20060253204A1The degree of freedom becomes largerReduce design marginComputer controlCAD circuit designSystem requirementsTrade offs

First several possible working points are stored with different mappings to available modules. Each of these working points involves different trade-offs for important criteria related to performance and costs. At the design stage, these trade-off points for the criteria are not calibrated to the actual run-time conditions. Subsequently, based on actual values of the leakage criteria caused by temperature variations and / or ageing at given run-time conditions for (a subset of) the working points, it is possible to calibrate the trade-off curves and use a run-time controller to select the most suited working points afterward for an actual circuit. These active working points are selected to just meet the necessary system requirements on performance, while minimizing any of the important cost parameters.

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW)

Internal combustion engine start controller

InactiveUS7594491B2Reduce loadAvoid yield lossElectrical controlMuscle operated startersPower semiconductor deviceElectric power system

An internal combustion engine start controller in a vehicle that includes: a power source; an internal combustion engine that is started by using electric power supplied from the power source; a first motor; and a first electric power converter that is constructed so as to be able to perform electric power conversion between the power source and the first motor through switching control of power semiconductor elements is provided. The start controller includes: a start detecting device for detecting whether the engine is in a starting operation; and a first frequency setting device that, when the engine is in a starting operation, sets a switching frequency of the first electric power converter to a frequency lower than that used when the engine is not in a starting operation.

Owner:TOYOTA JIDOSHA KK

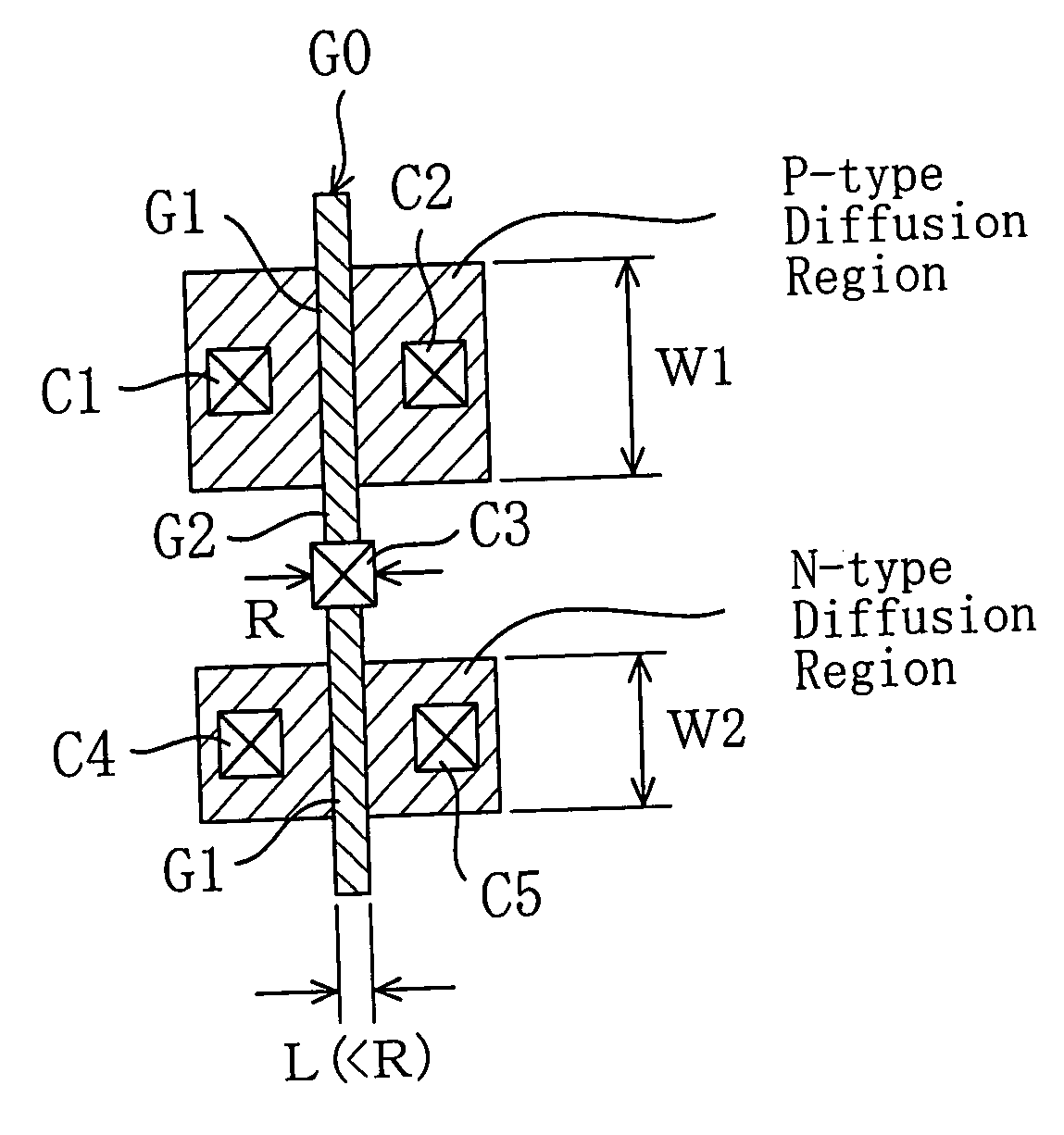

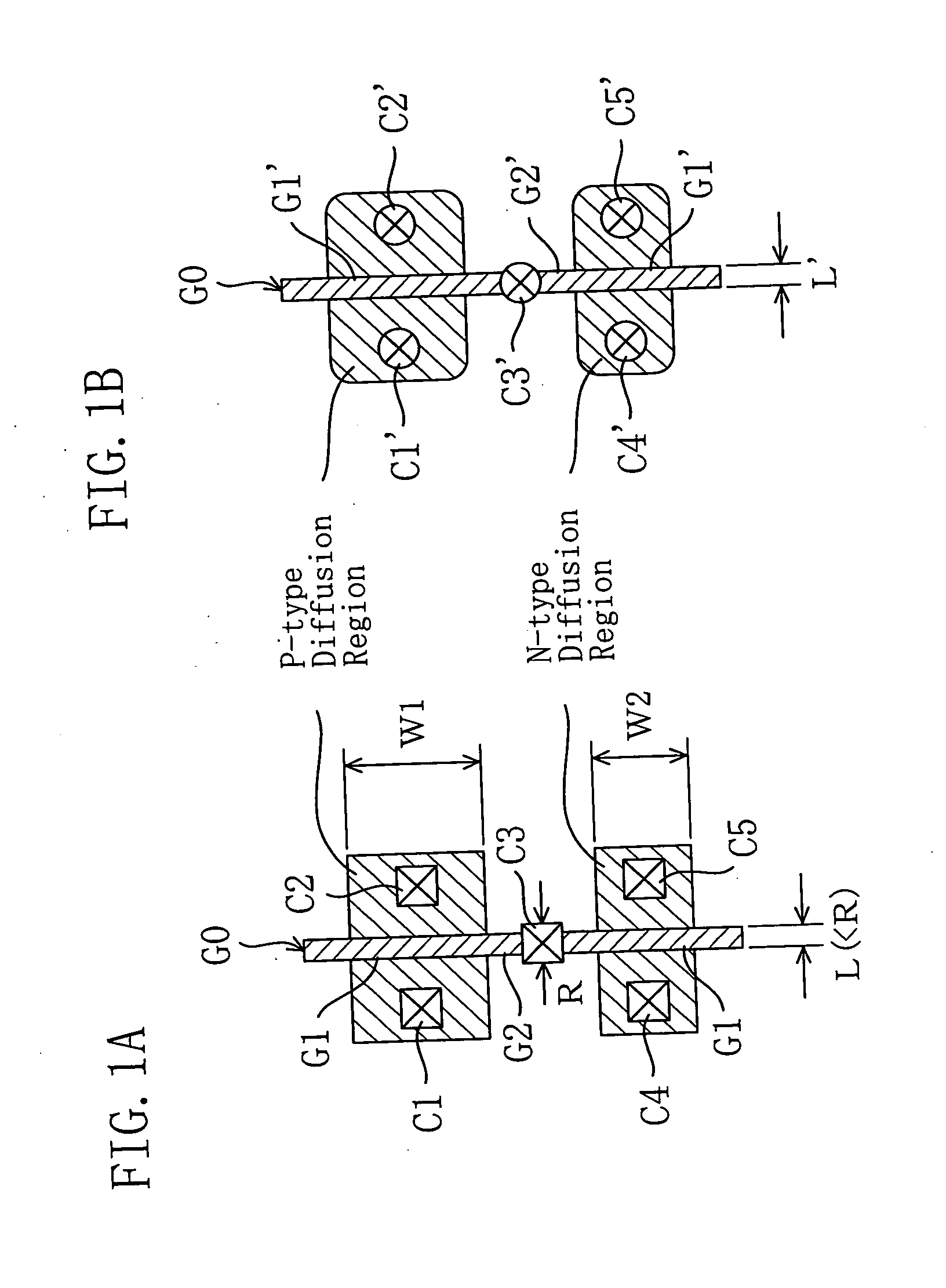

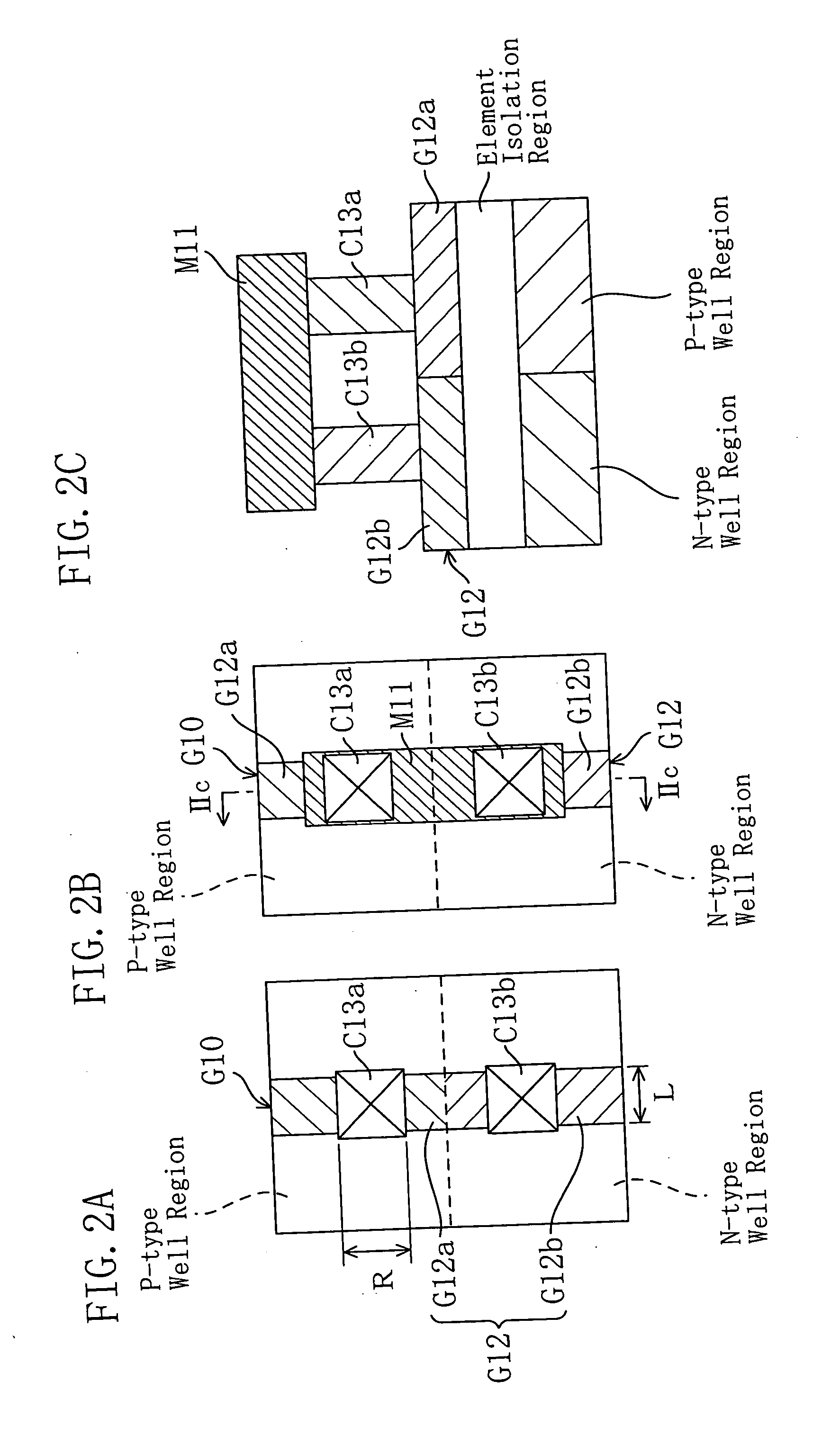

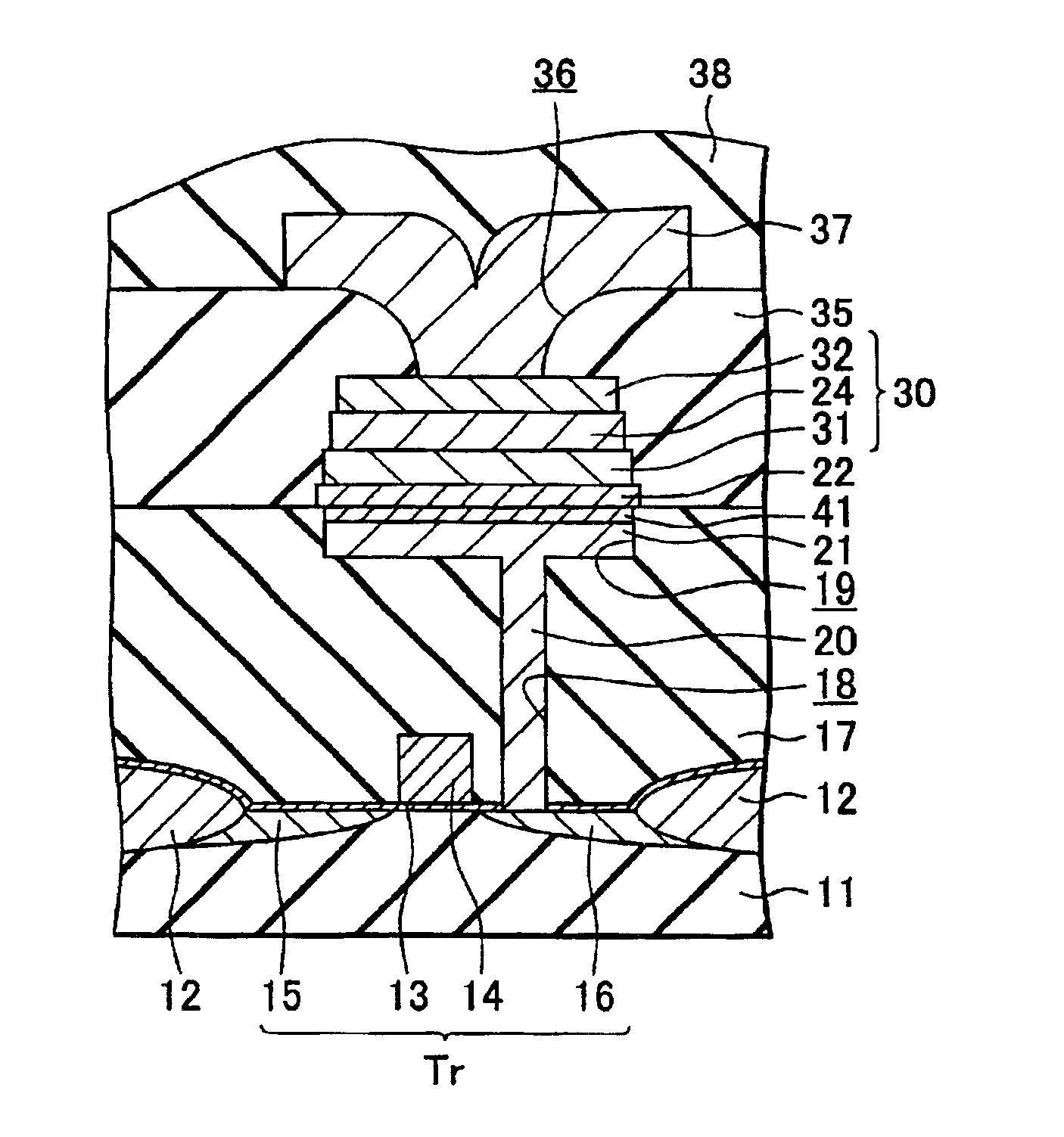

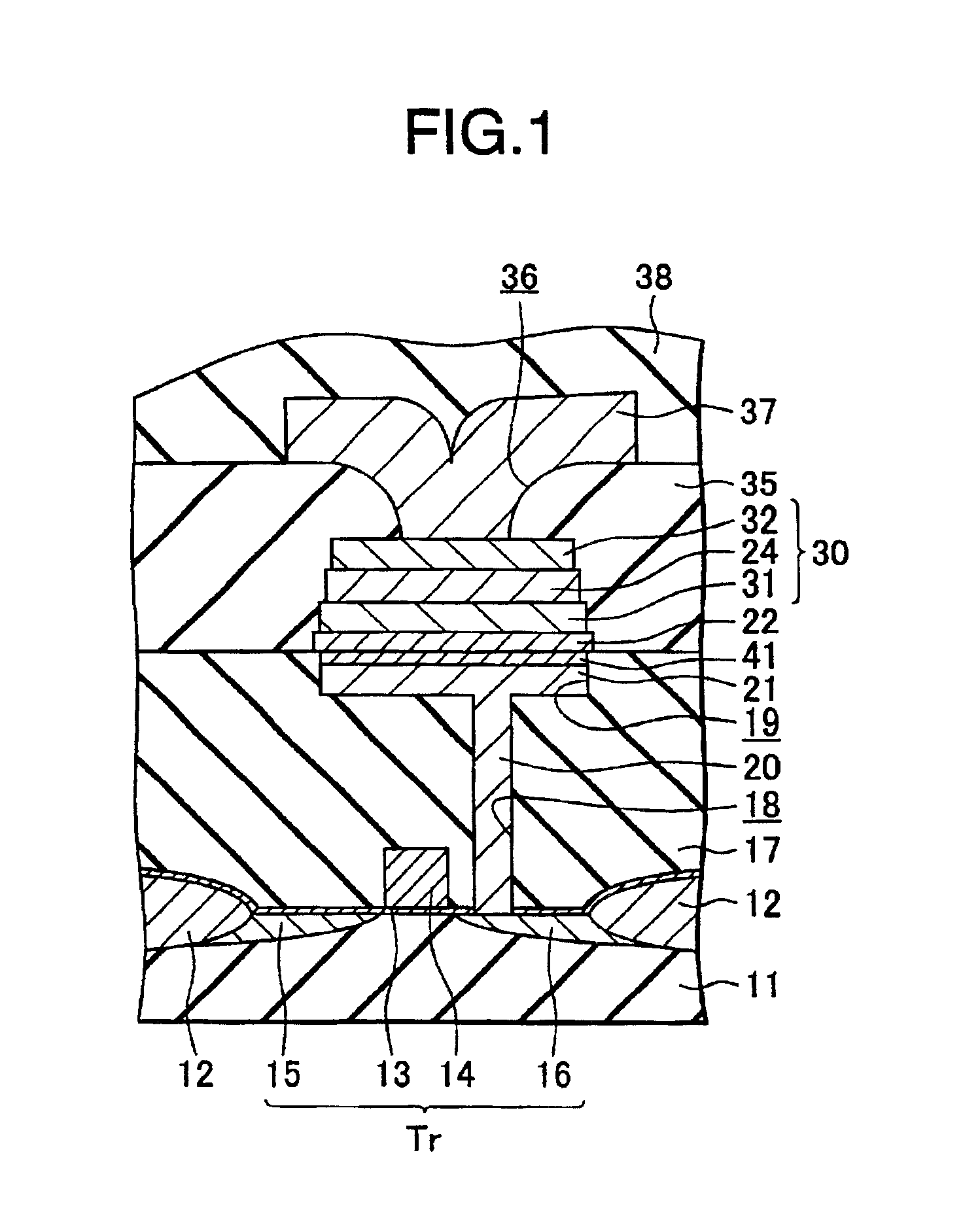

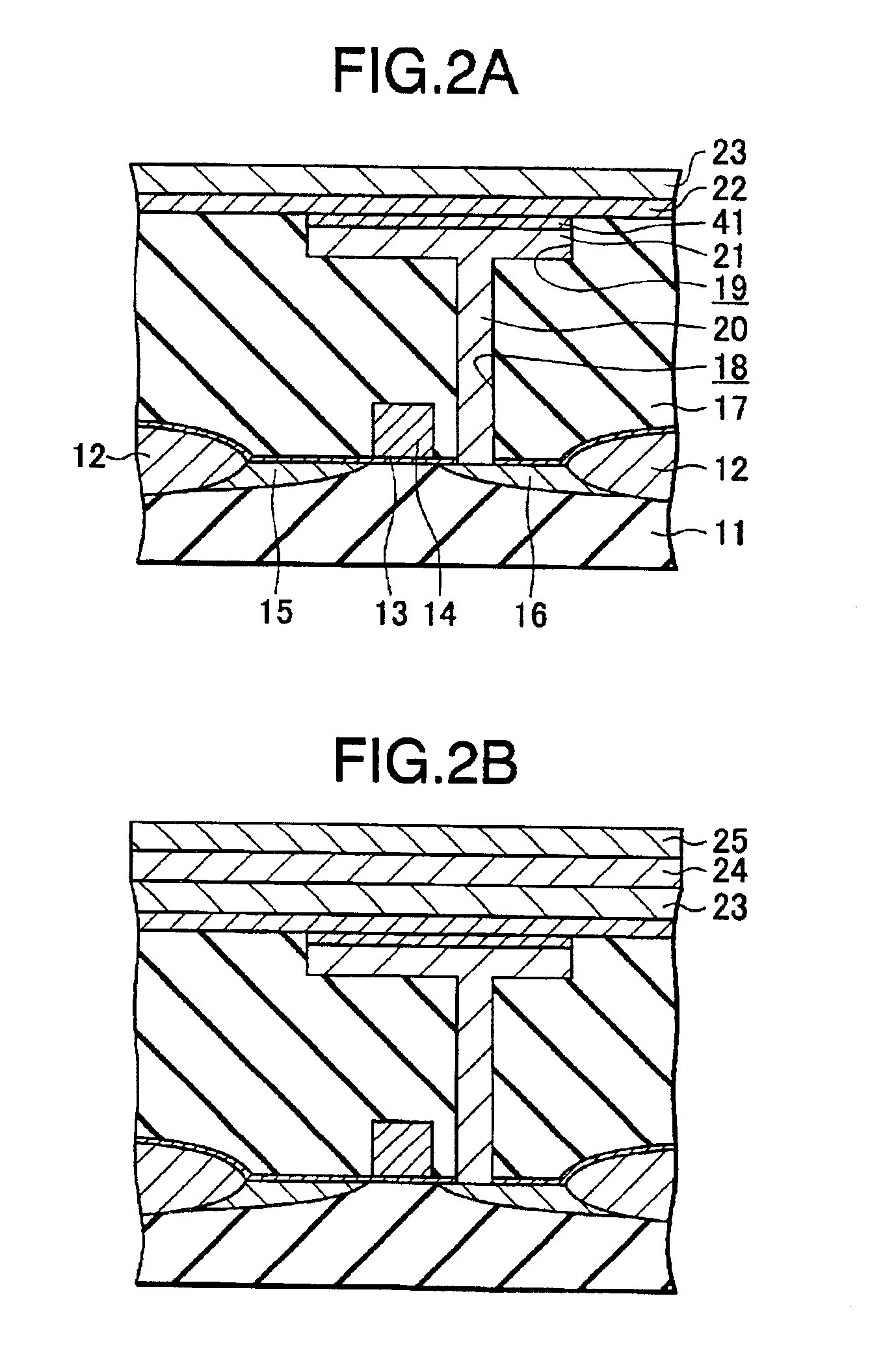

Semiconductor device

ActiveUS20060017070A1Planar area of becomes largeImprove performanceSolid-state devicesSemiconductor/solid-state device manufacturingElectrical conductorDevice material

A semiconductor device includes a semiconductor substrate; a diffusion region which is formed in the semiconductor substrate and serves as a region for the formation of a MIS transistor; an element isolation region surrounding the diffusion region; at least one gate conductor film which is formed across the diffusion region and the element isolation region, includes a gate electrode part located on the diffusion region and a gate interconnect part located on the element isolation region, and has a constant dimension in the gate length direction; and an interlayer insulating film covering the gate electrode. The semiconductor device further includes a gate contact which passes through the interlayer insulating film, is connected to the gate interconnect part, and has the dimension in the gate length direction larger than the gate interconnect part.

Owner:GK BRIDGE 1

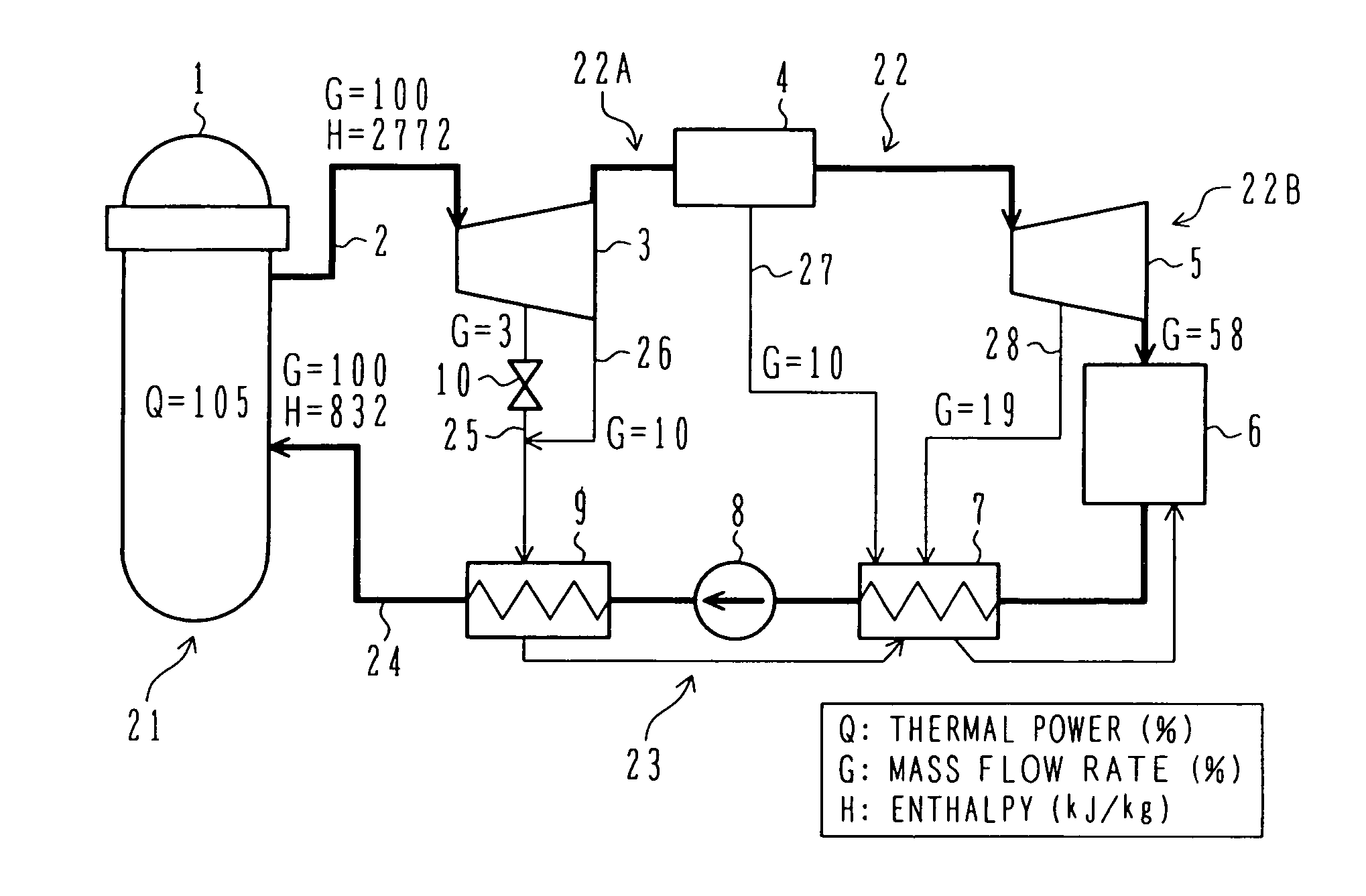

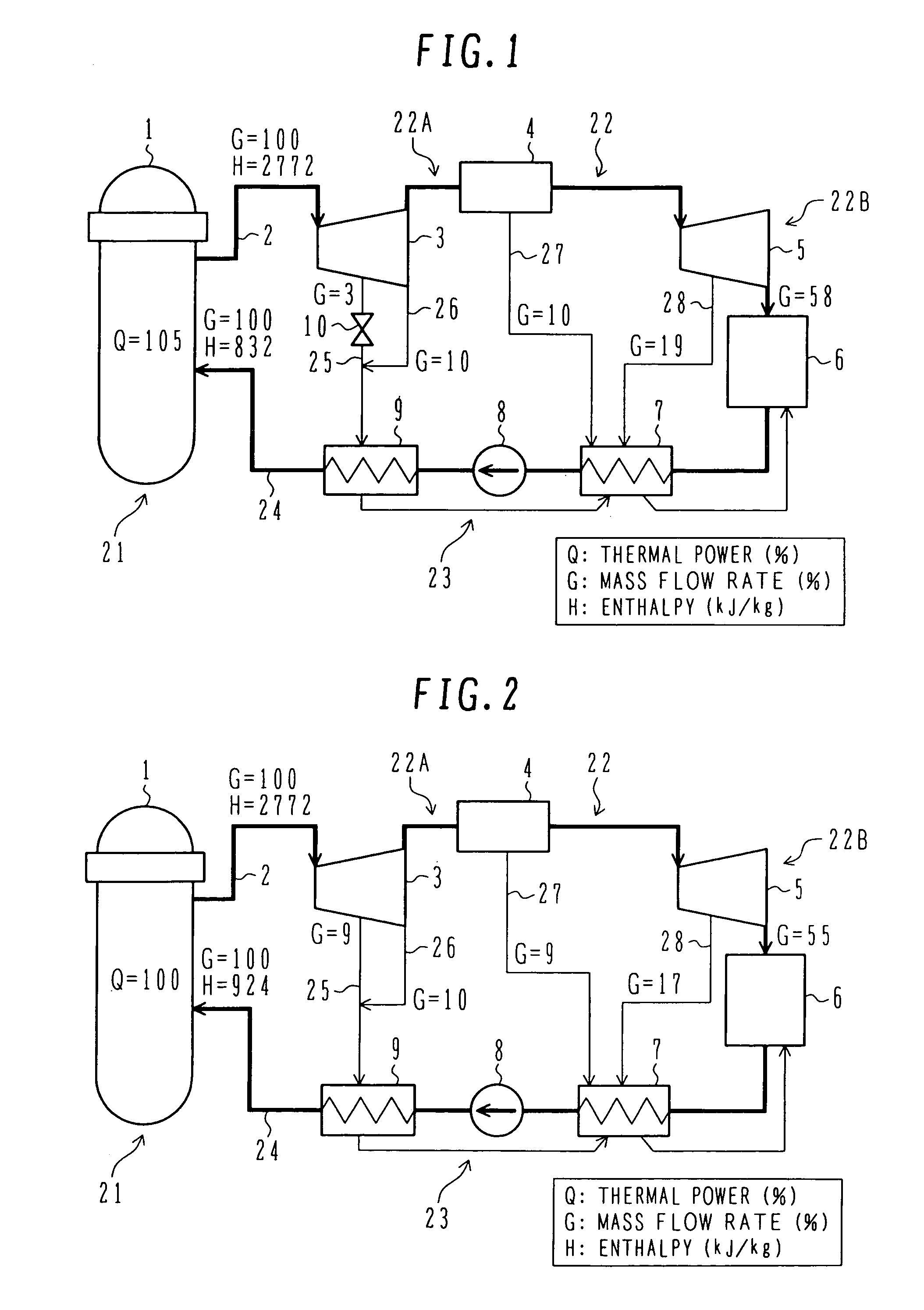

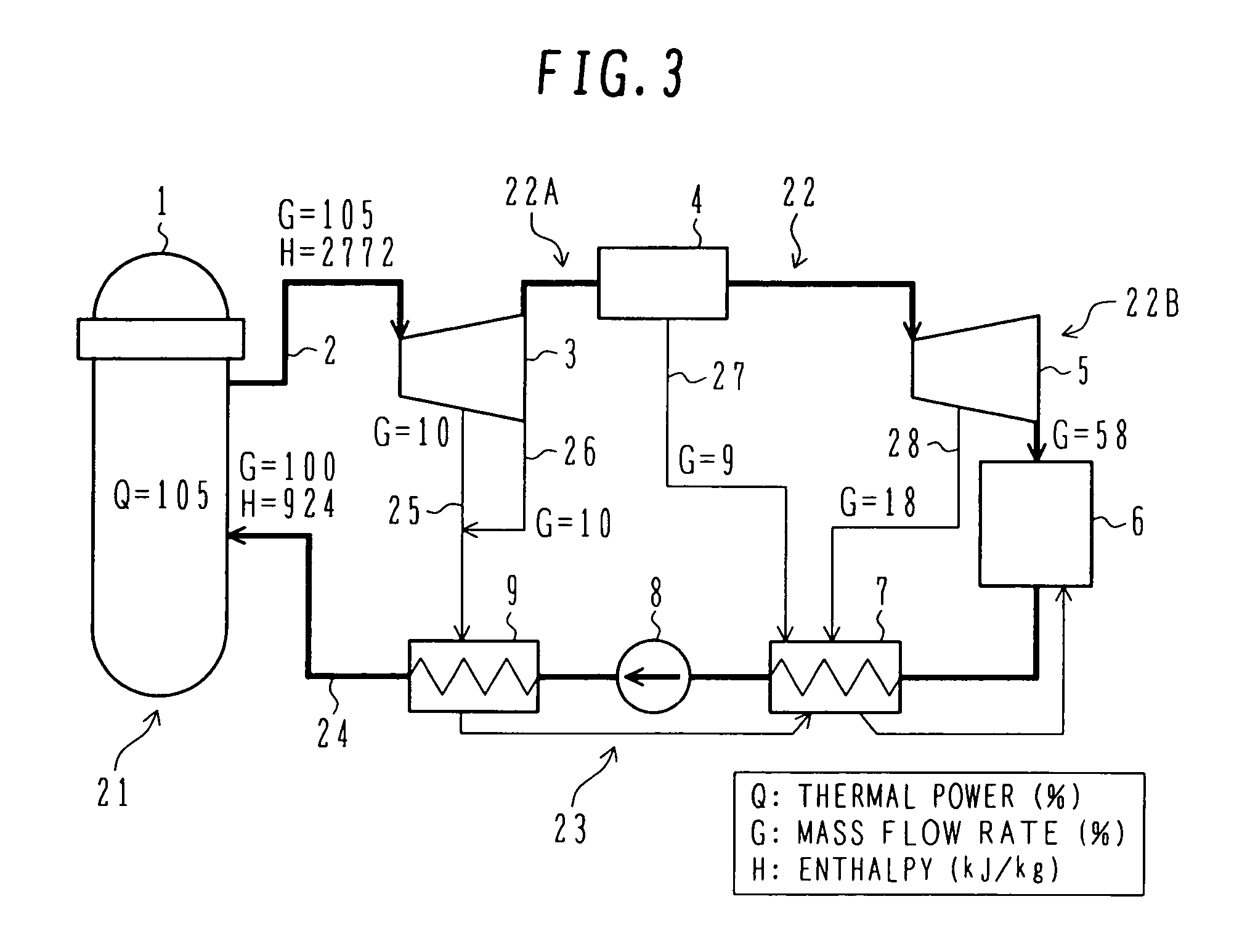

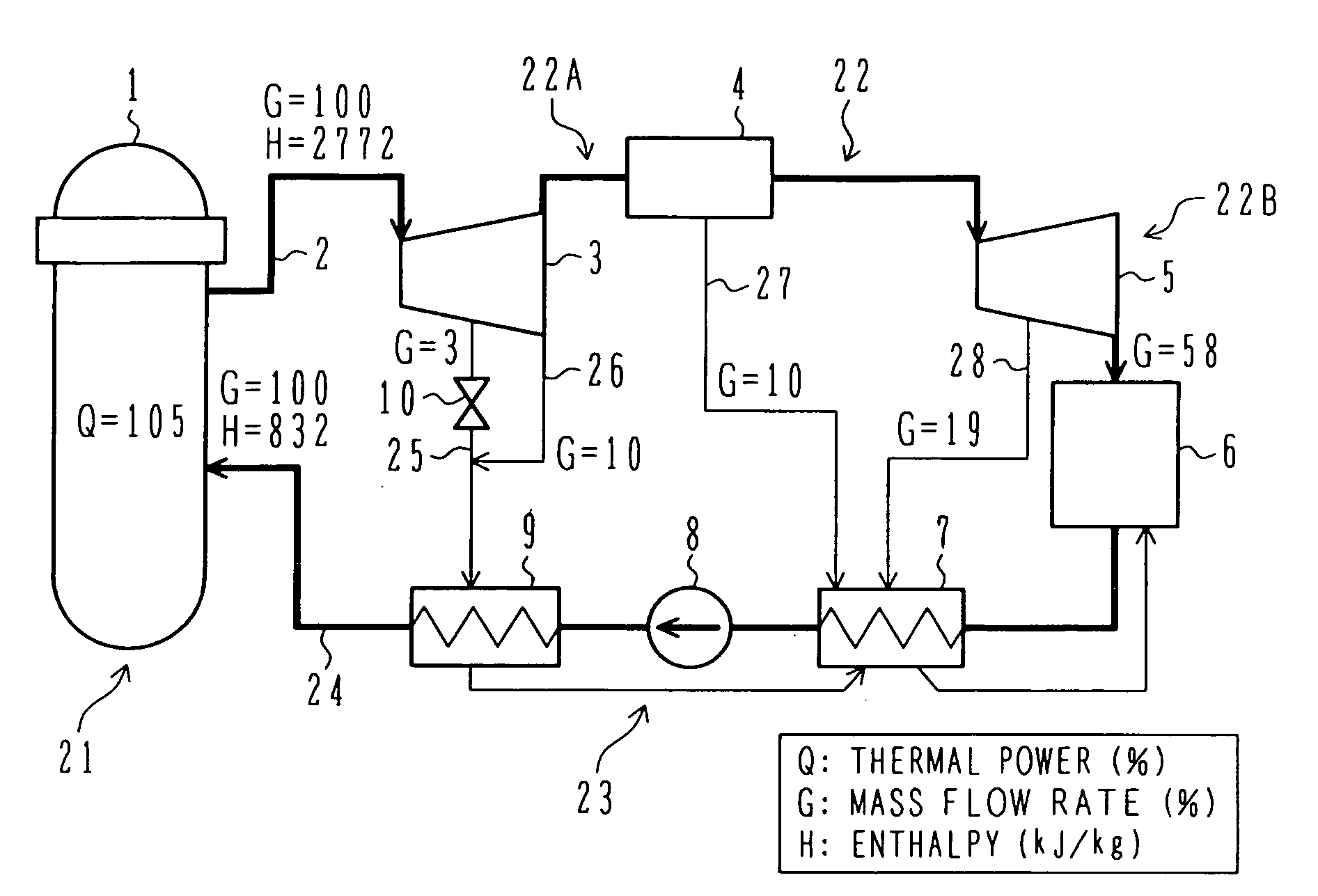

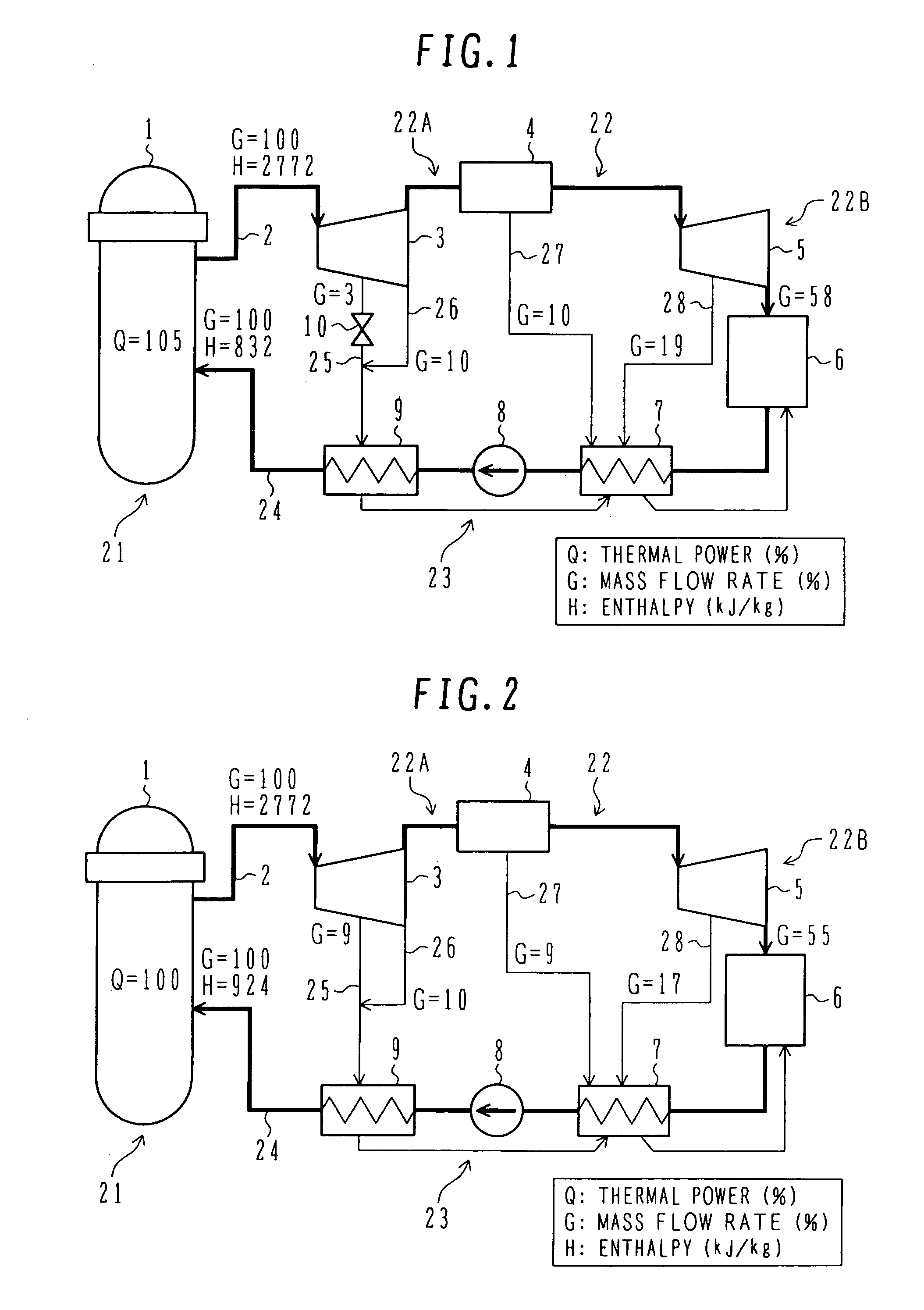

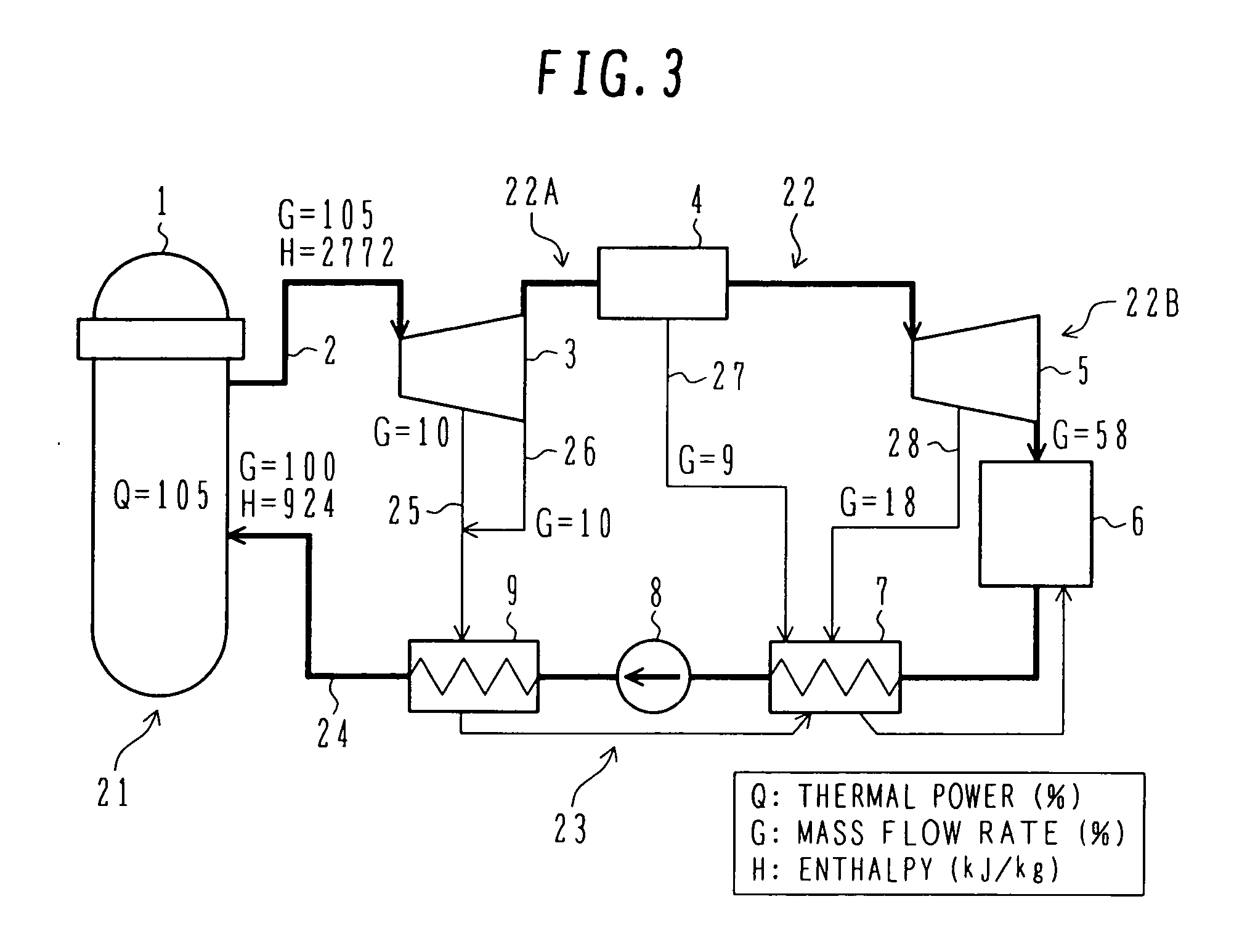

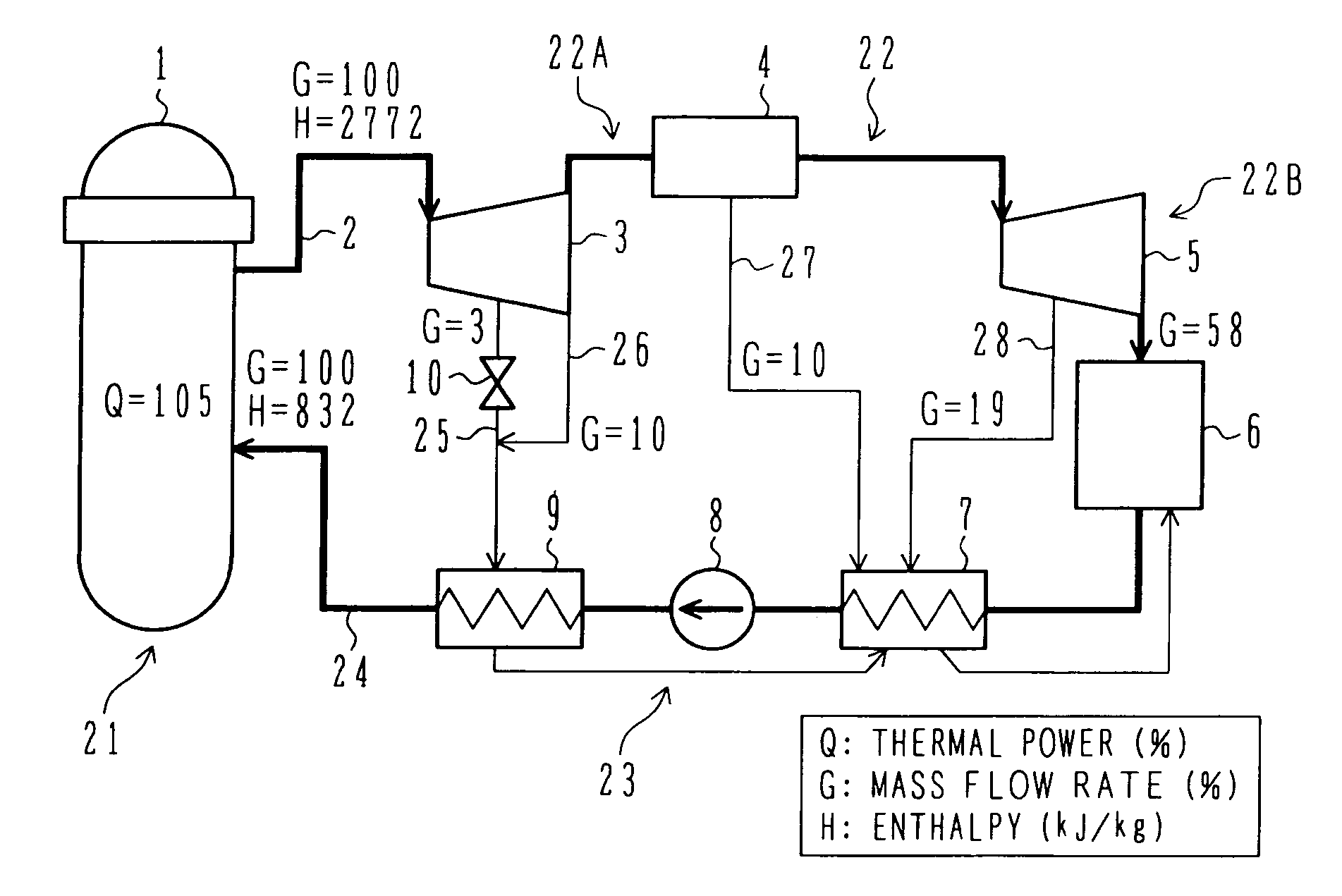

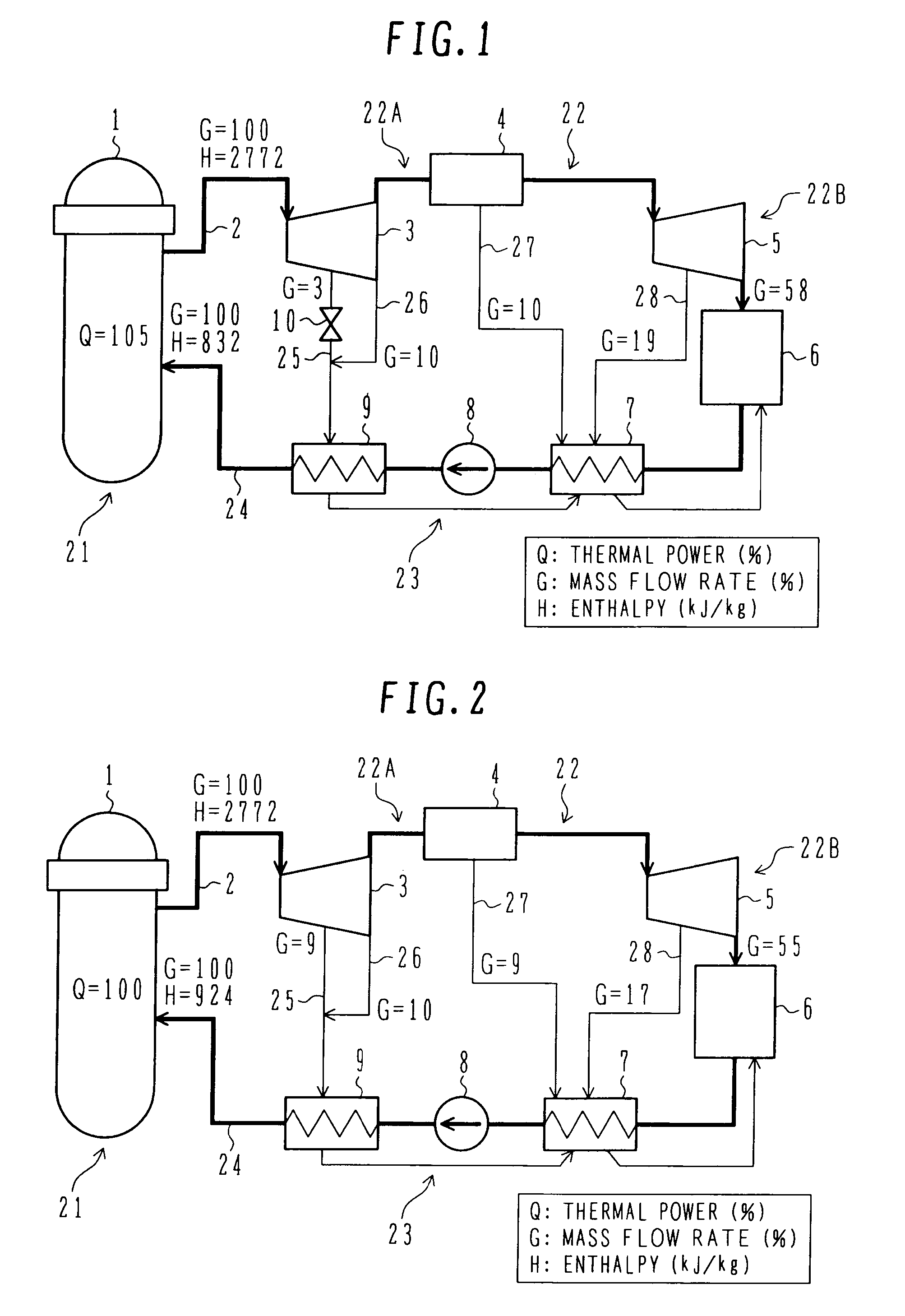

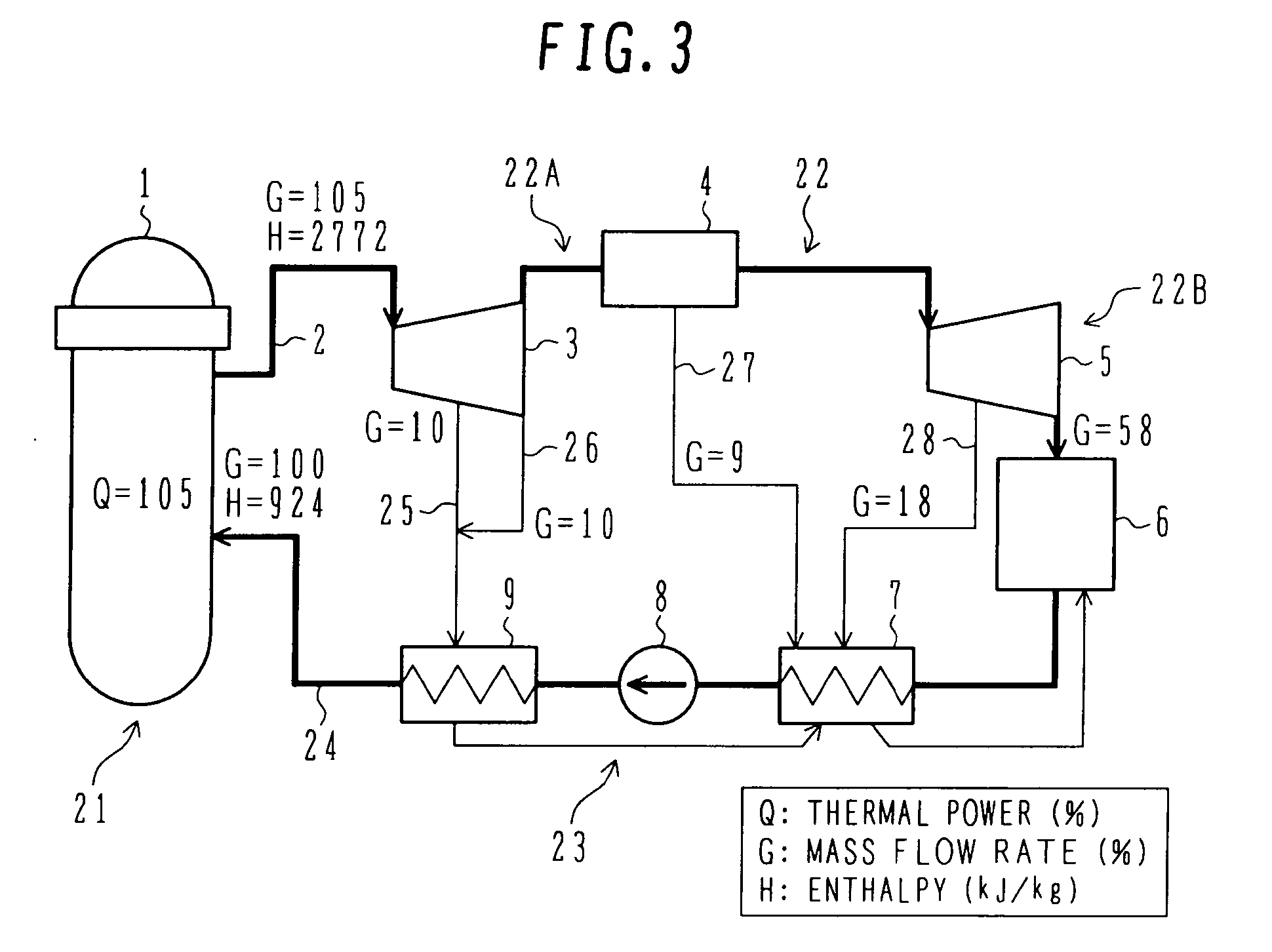

Operation method of nuclear power plant

ActiveUS7614233B2Increase thermal powerIncrease flow rateNuclear energy generationNuclear power plant controlNuclear reactorNuclear power

In a nuclear power plant, thermal power in a second operation cycle of a nuclear reactor is uprated from thermal power in a first operation cycle preceding the second operation cycle by at least one operation cycle. A proportion of steam extracted from a steam system and introduced to a feedwater heater, which is in particular extracted from an intermediate point and an outlet of a high pressure turbine, with respect to a flow rate of main steam, is reduced in the second operation cycle from that in the first operation cycle such that the temperature of feedwater discharged from the feedwater heater is lowered by 1° C. to 40° C. in the second operation cycle.

Owner:HITACHI-GE NUCLEAR ENERGY LTD

FCM (full ceramic microcapsulated) fuel effective multigroup cross section acquiring method

InactiveCN109493924AFast implementation of design calculationsCalculation speedChemical structure searchSelf screeningGroup method

Disclosed is an FCM fuel effective multigroup cross section acquiring method. The FCM fuel effective multigroup cross section acquiring method comprises, in a resonant energy section and based on a superfine group method, solving a TRISO (tristructure isotropic) particle and matrix material containing one-dimensional sphere model to obtain superfine group defect factors; through the superfine group defect factors, correcting the superfine group cross section of all nuclides to homogenize particles and matrix; through Dancoff factor equivalence, acquiring the equivalent one-dimensional rod model of every fuel rod of an FCM fuel, solving the superfine group slowing-down equation of the one-dimensional rod models to acquire the effective self-shielding cross section of the resonant energy section; in a heat energy section, through penetration probability and collision probability equivalence, acquiring multigroup defect factors, correcting the multigroup cross sections of all the nuclidesthrough the multigroup defect factors to homogenize fuel and matrix and to acquire the effective multigroup cross sections of the heat energy section. The FCM fuel effective multigroup cross sectionacquiring method can help effectively process the dual heterogenous effects of the FCM fuel to acquire a precise effective self-screening cross section.

Owner:XI AN JIAOTONG UNIV

Operation method of nuclear power plant

ActiveUS20070000250A1Increase thermal powerIncrease flow rateNuclear energy generationNuclear power plant controlNuclear powerHigh pressure

A nuclear power plant and an operation method of the nuclear power plant, which can uprate plant power without greatly modifying the construction of plant equipment, while keeping a core's pressure loss characteristic, a safety margin, and a design margin in the transient state substantially the same as those before the power uprate. Thermal power in a second operation cycle of a nuclear reactor is uprated from thermal power in a first operation cycle preceding the second operation cycle at least one operation cycle. A proportion of steam extracted from a steam system and introduced to a feedwater heater, which is in particular extracted from an intermediate point and an outlet of a high pressure turbine, with respect to a flow rate of main steam is reduced in the second operation cycle from that in the first operation cycle such that temperature of feedwater discharged from the feedwater heater lowers in the range of 1° C. to 40° C. in the second operation cycle.

Owner:HITACHI-GE NUCLEAR ENERGY LTD

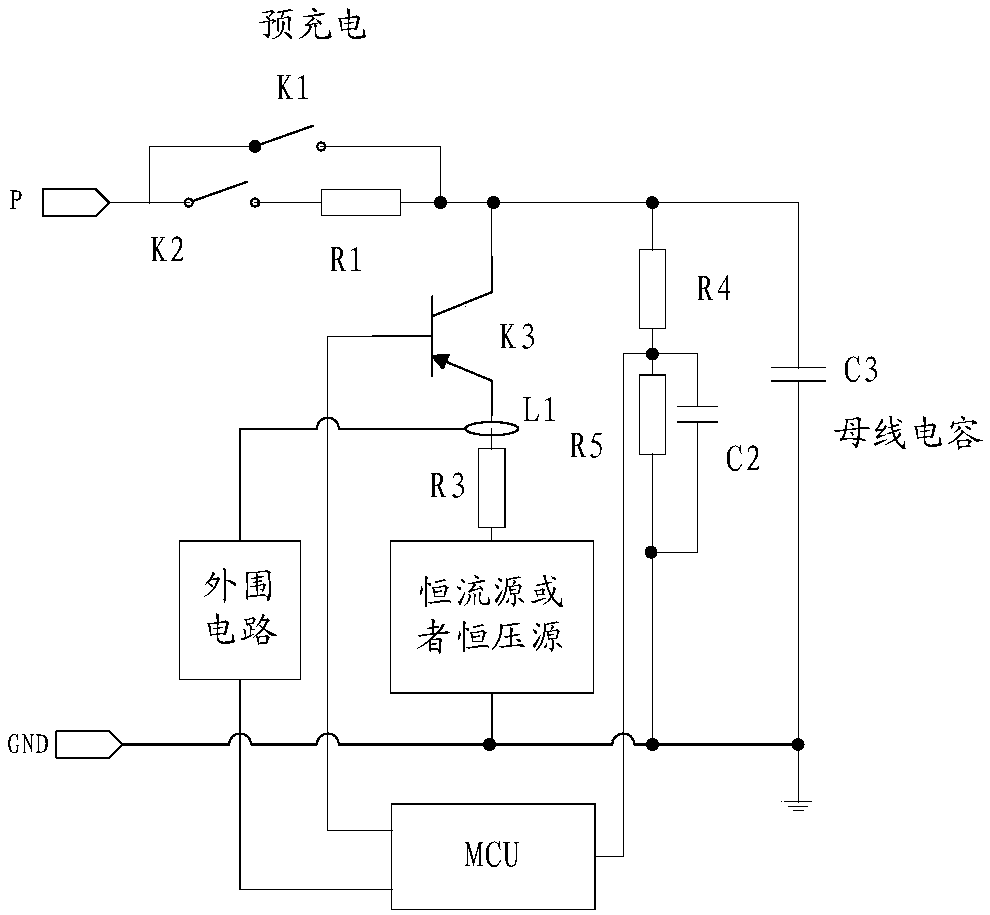

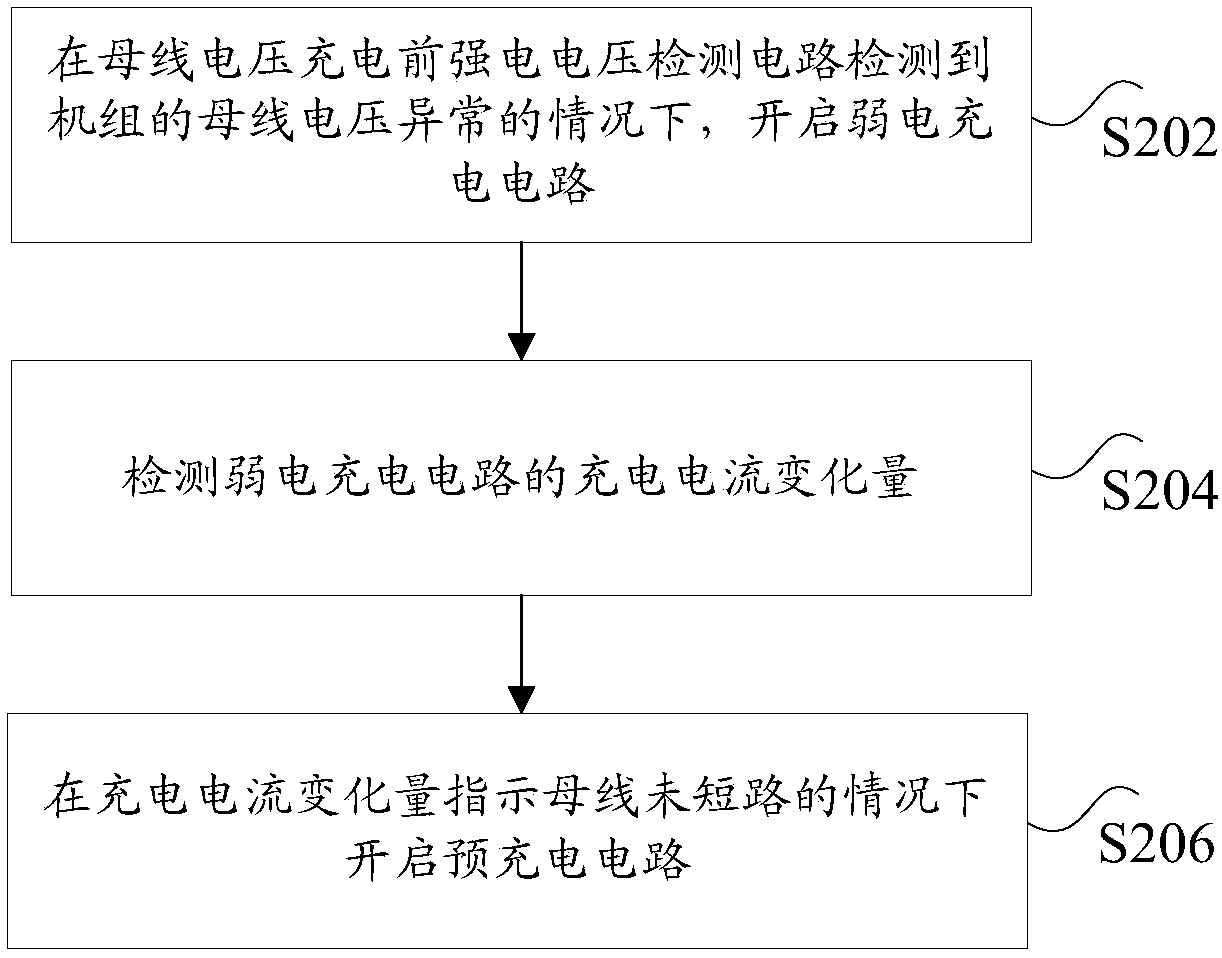

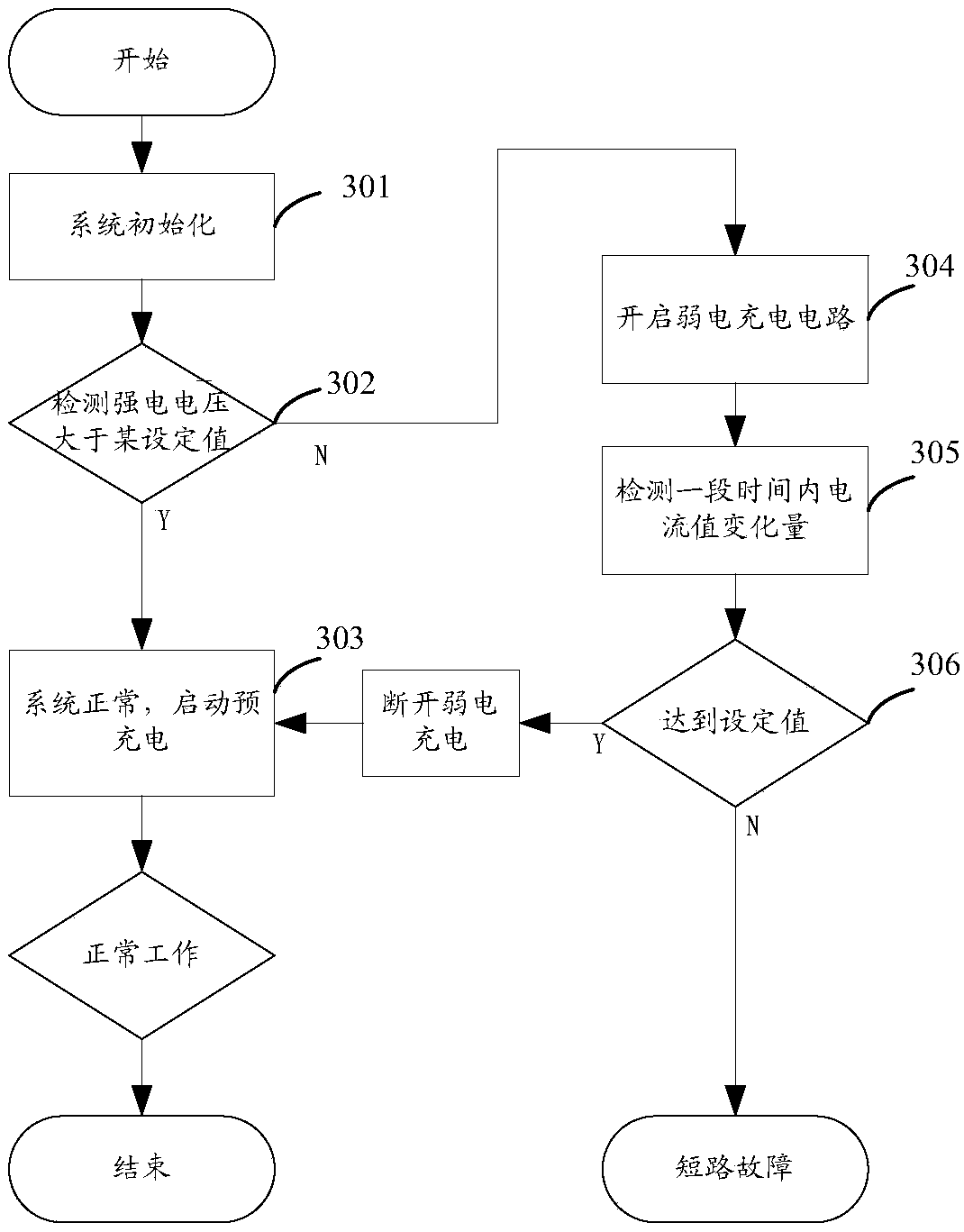

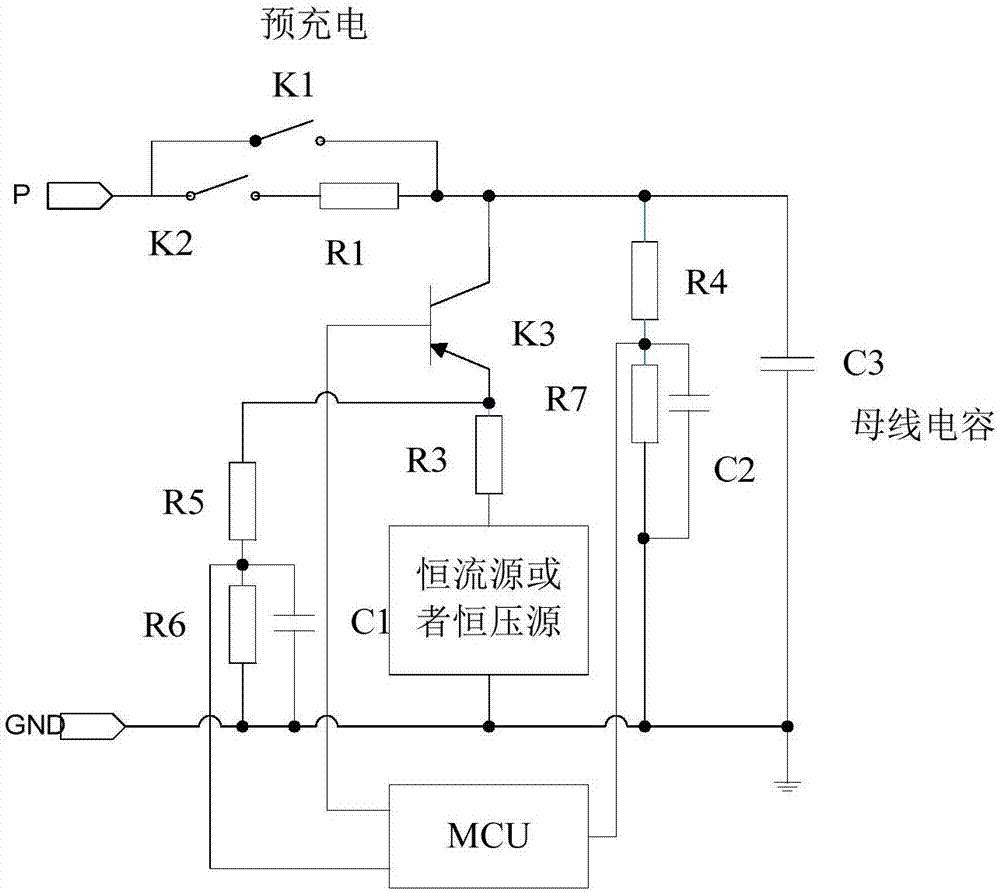

Bus short-circuit detection method and circuit, storage medium and processor

ActiveCN108267665AReduce design marginFix unsafe technical issuesTesting dielectric strengthShort-circuit testingCharge currentPre-charge

The present invention discloses a bus short-circuit detection method and circuit, a storage medium and a processor. The method comprises the steps of: starting a weak current charge circuit in a condition that a strong voltage detection circuit detects that a bus voltage of a unit is abnormal prior to bus voltage charge, wherein the weak current charge circuit is configured to charge the bus; detecting the charge current variation of the weak current charge circuit; and starting a pre-charge circuit in a condition that the e charge current variation shows that the bus is not short-circuit. Thetechnical problem is solved that a current detection circuit detects the bus short-circuit to cause that a rear-end circuit is not safe.

Owner:GREE ELECTRIC APPLIANCES INC

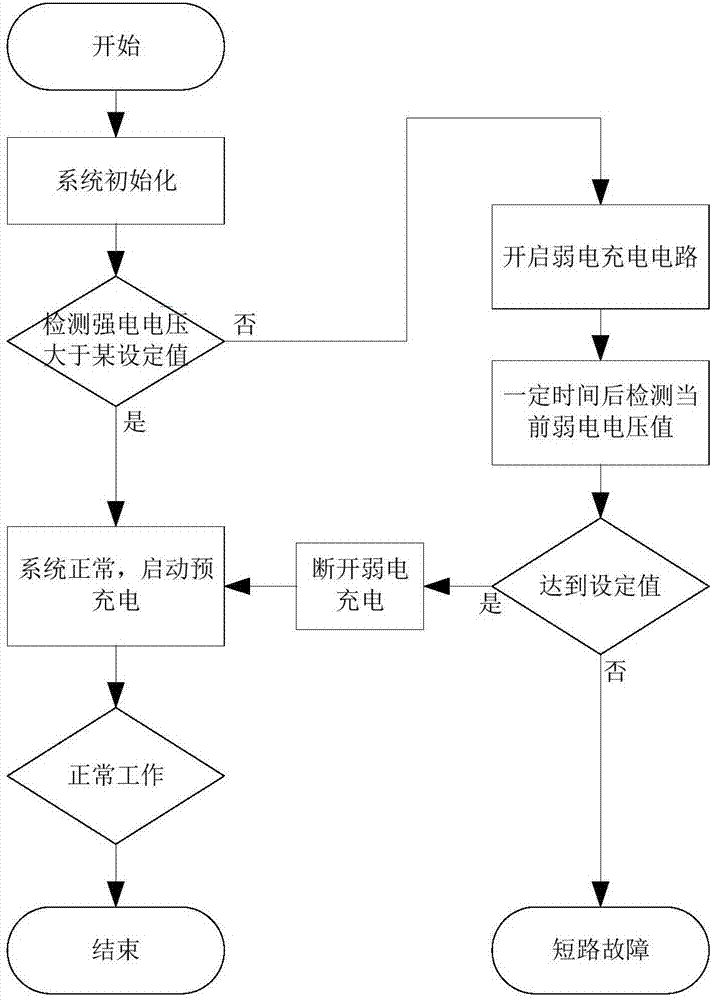

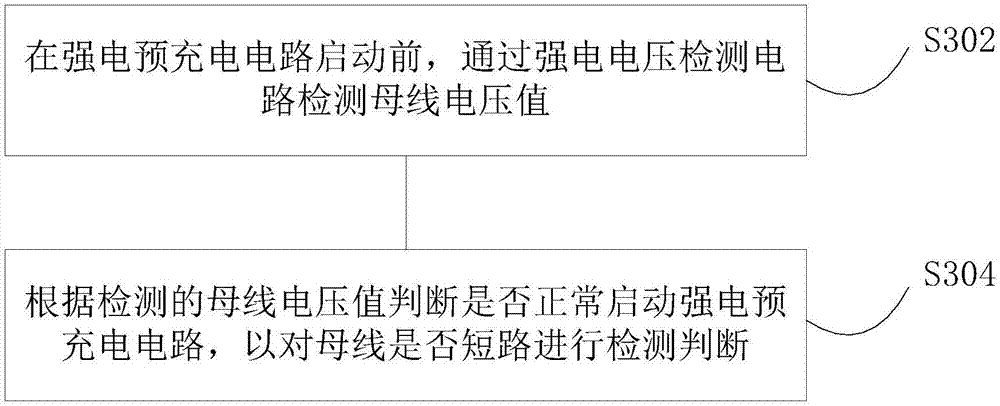

DC bus short-circuit detection method and device and detection circuit

ActiveCN108008235ASolve the problem of destroying circuit componentsImprove securityElectrical testingElectricityPre-charge

The invention discloses a DC bus short-circuit detection method and device and a detection circuit. The method comprises the steps of detecting a bus voltage value through a strong-current voltage detection circuit before a strong-current pre-charge circuit is started; and judging, according to the detected bus voltage value, whether the strong-current pre-charge circuit is normally started, so asto detect and judge whether the bus is short-circuited. According to the invention, the problem that in the prior art, if a short-circuit condition occurs during power-up of the strong-current circuit, circuit components may be destroyed is solved, and the circuit safety is improved.

Owner:GREE ELECTRIC APPLIANCES INC

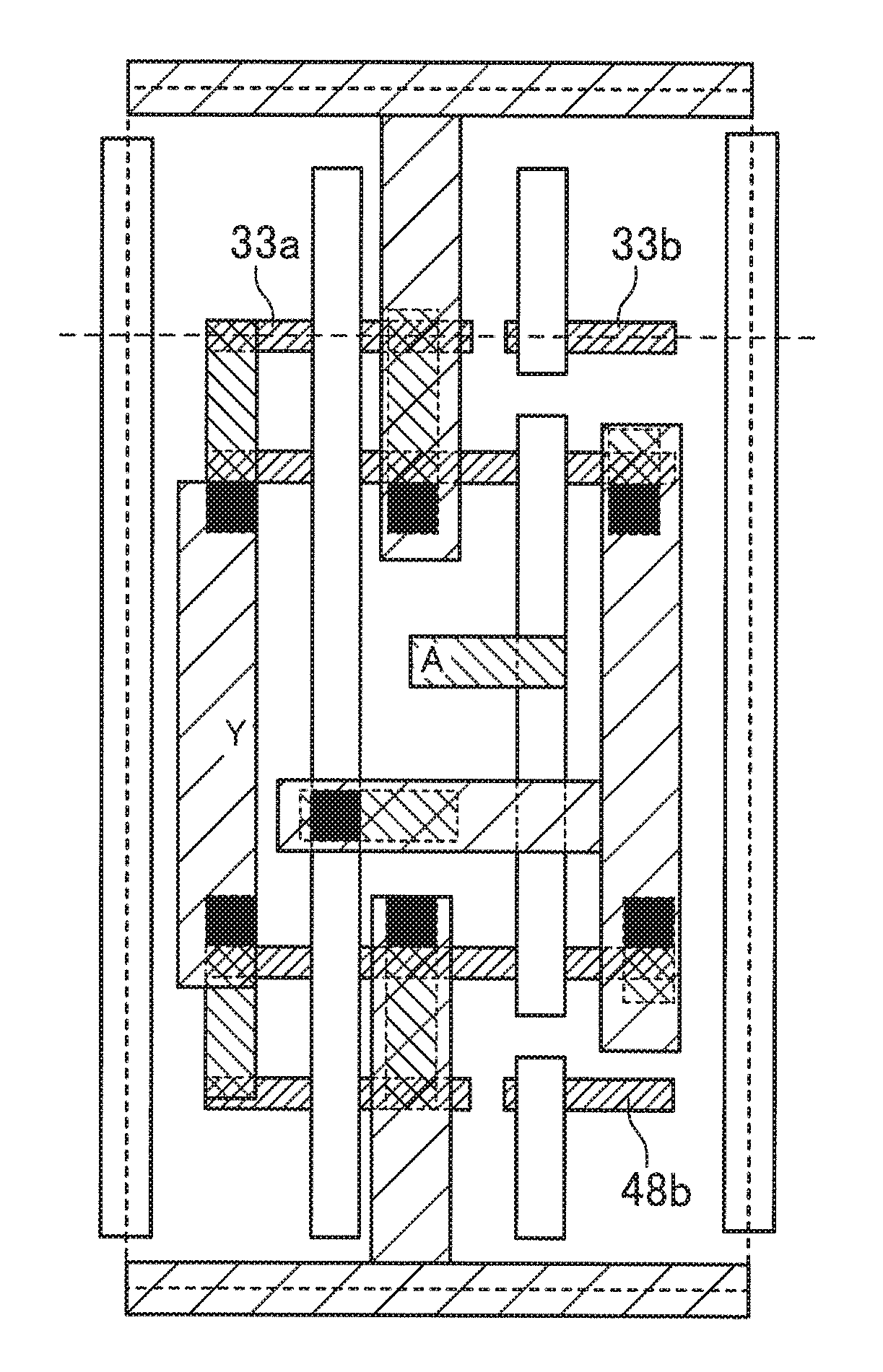

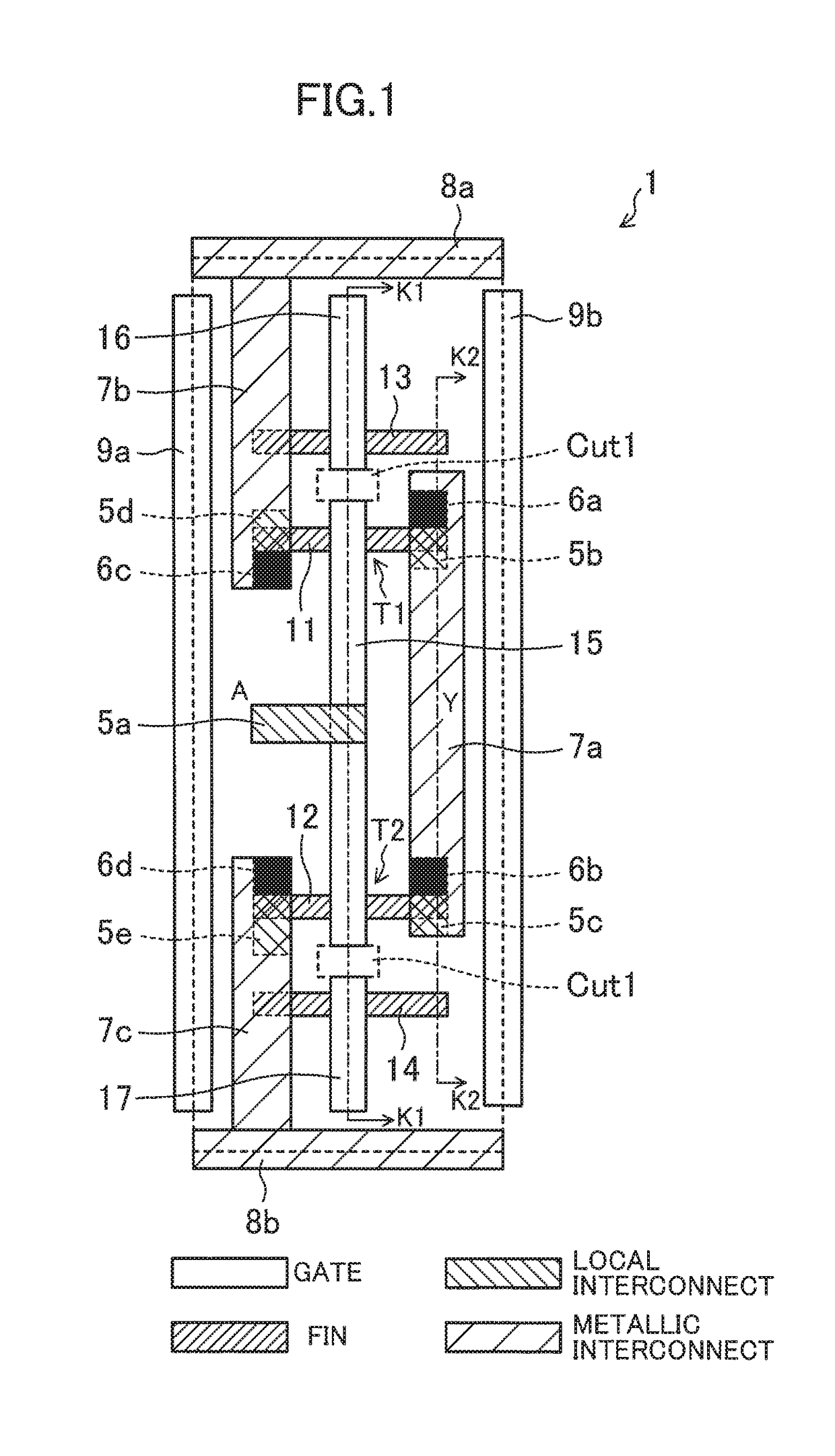

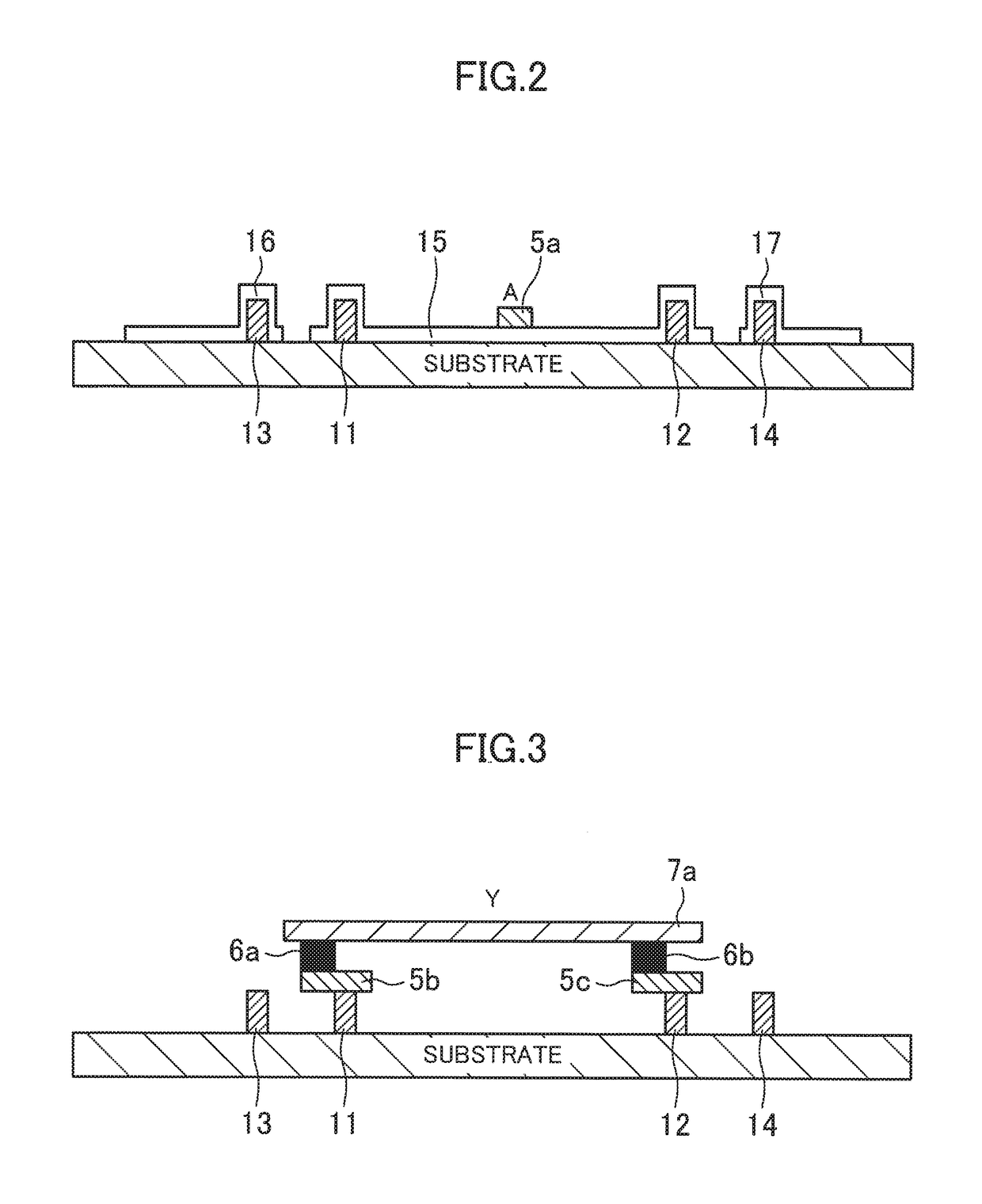

Semiconductor integrated circuit device

ActiveUS20180190640A1Improve performanceReduce design marginTransistorSemiconductor/solid-state device detailsEngineeringSemiconductor

Disclosed herein is a semiconductor integrated circuit device which includes a standard cell with a plurality of fins extending in a first direction and arranged in a second direction that is perpendicular to the first direction. An active fin of the fins forms part of an active transistor. A dummy fin of the fins is disposed between the active fin and an end of the standard cell.

Owner:SOCIONEXT INC

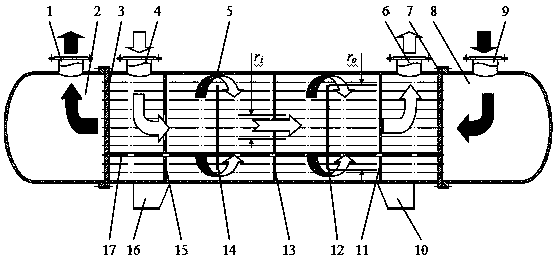

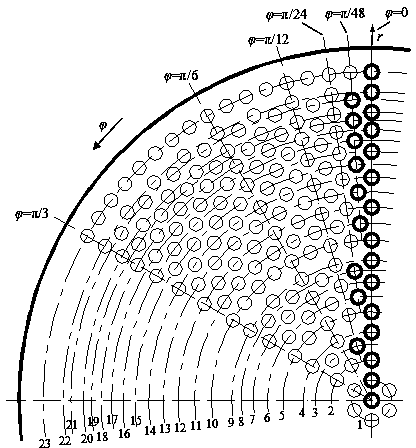

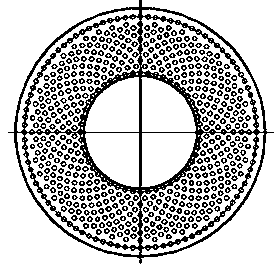

Shell-and-tube heat exchanger and method for machining plate holes in shell-and-tube heat exchanger

ActiveCN103968688AReduce design marginGuaranteed heat exchange effectHeat exchanger casingsStationary tubular conduit assembliesShell and tube heat exchangerPlate heat exchanger

The invention relates to a heat transfer technology and provides a shell-and-tube heat exchanger and a method for machining plate holes in the shell-and-tube heat exchanger. According to the technology, heat exchange tubes are distributed in a radial topological mode in cooperation with circular-ring-shaped and disk-shaped baffle plates which are arranged alternately, so that shell-pass fluid uniformly flows through all the heat exchange tubes in the radial direction, and the utilization rate of the heat exchange tubes is increased. The shell-and-tube heat exchanger mainly comprises a barrel body, tube plates, tube boxes, the heat exchange tubes and the baffle plates. The baffle plates comprise the circular-ring-shaped baffle plates and the disk-shaped baffle plates, the circular-ring-shaped baffle plates and the disk-shaped baffle plates are arranged alternately, and the total number of the baffle plates is an odd number. The heat exchange tubes are arranged on concentric circles with different diameters with the symmetrical axis of the heat exchanger as the center and are distributed evenly in the circumferential direction. The spacing between the heat exchange tubes is not a definite value, and the minimum spacing is 1.25 times larger than or equal to the outer diameter of each heat exchange tube.

Owner:NANJING UNIV OF TECH

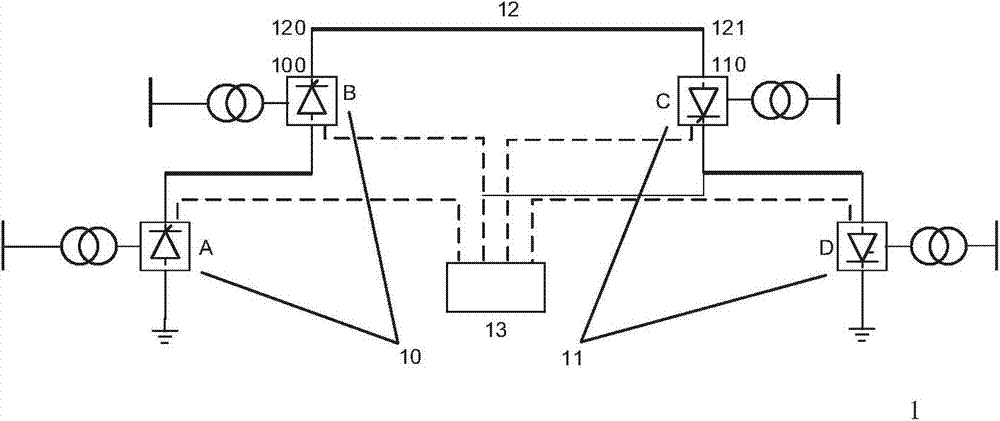

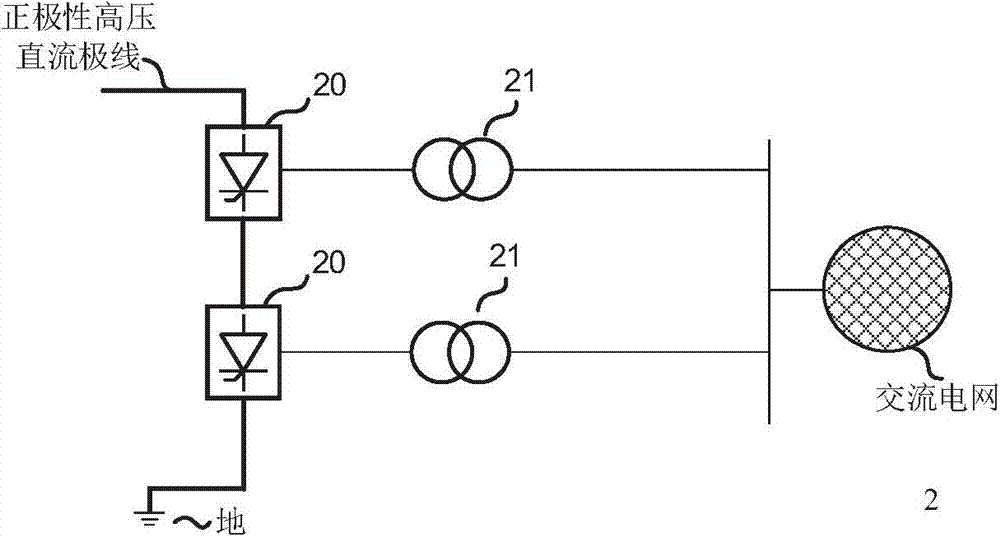

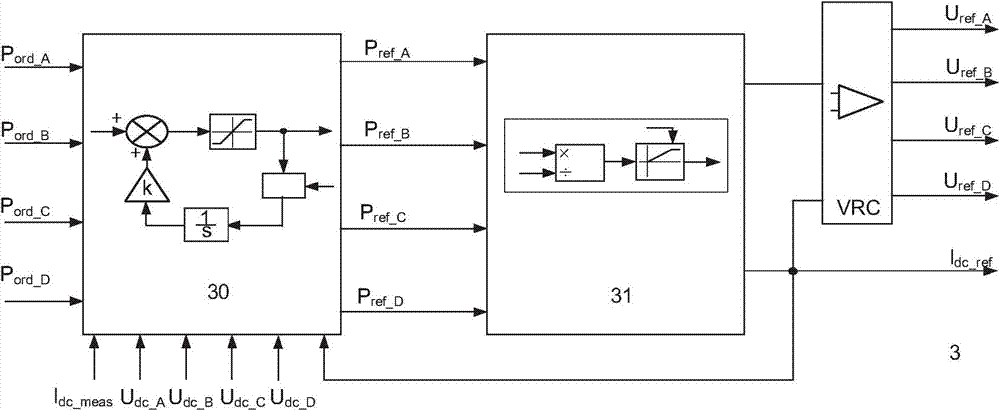

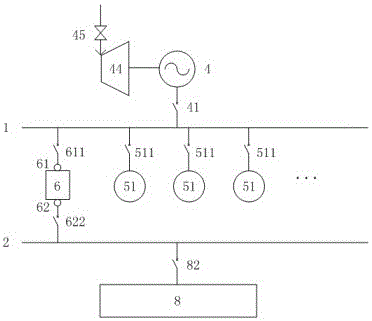

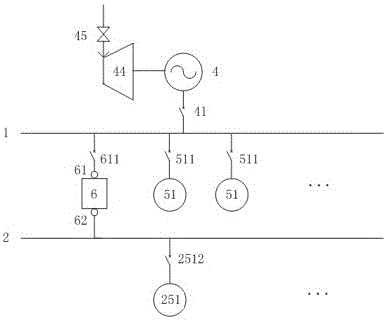

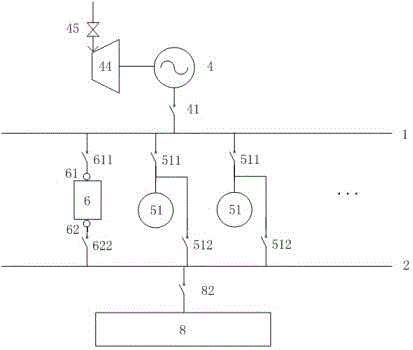

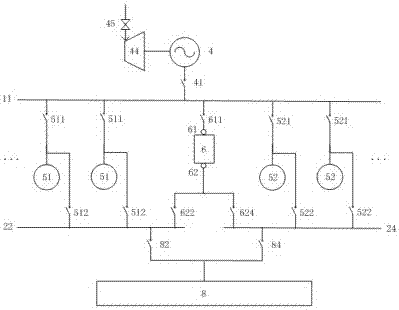

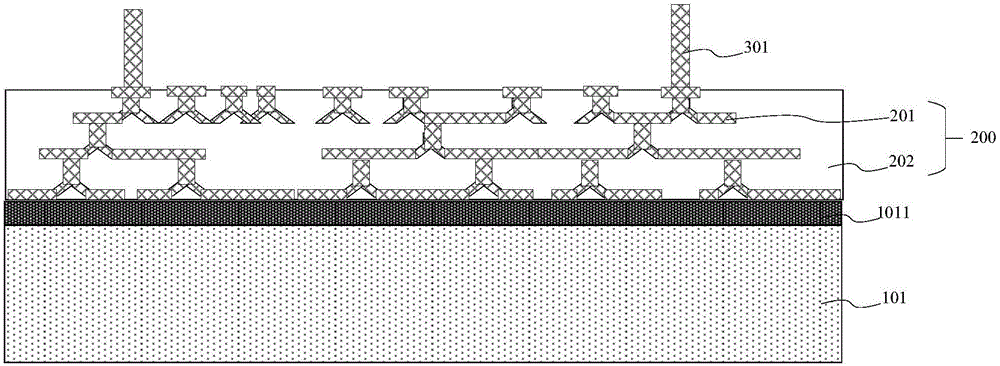

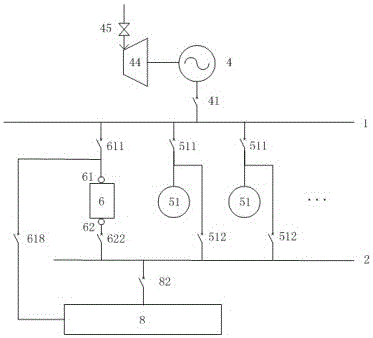

Tandem type multi-terminal direct-current power transmission system and loss compensation method thereof

ActiveCN103762584ACompensate for power lossReduced DC voltage increasesElectric power transfer ac networkDc source parallel operationPower transmissionPower loss

The invention provides a tandem type multi-terminal direct-current power transmission system and a loss compensation method thereof. The system comprises a first converter station unit group, a second converter station unit group, and a controller. The controller is capable of controlling one converter station unit among the at least one first converter station unit and a plurality of second converter station units to work as a current control terminal so as to maintain the constant state of the direct current, obtaining information including direct-current voltage values of the at least one first converter station unit and the plurality of second converter station units and the current value of a high-voltage direct-current polar line, and adjusting the direct voltage of at least one non-constant current terminal converter station unit among the at least one first converter station unit and the plurality of second converter station units based on the information so as to compensate the power loss of the high-voltage direct-current polar line conveniently. With the system and the method, the power loss of the high-voltage direct-current polar line can be compensated and the direct voltage of the current setting terminal can be decreased.

Owner:HITACHI ENERGY SWITZERLAND AG

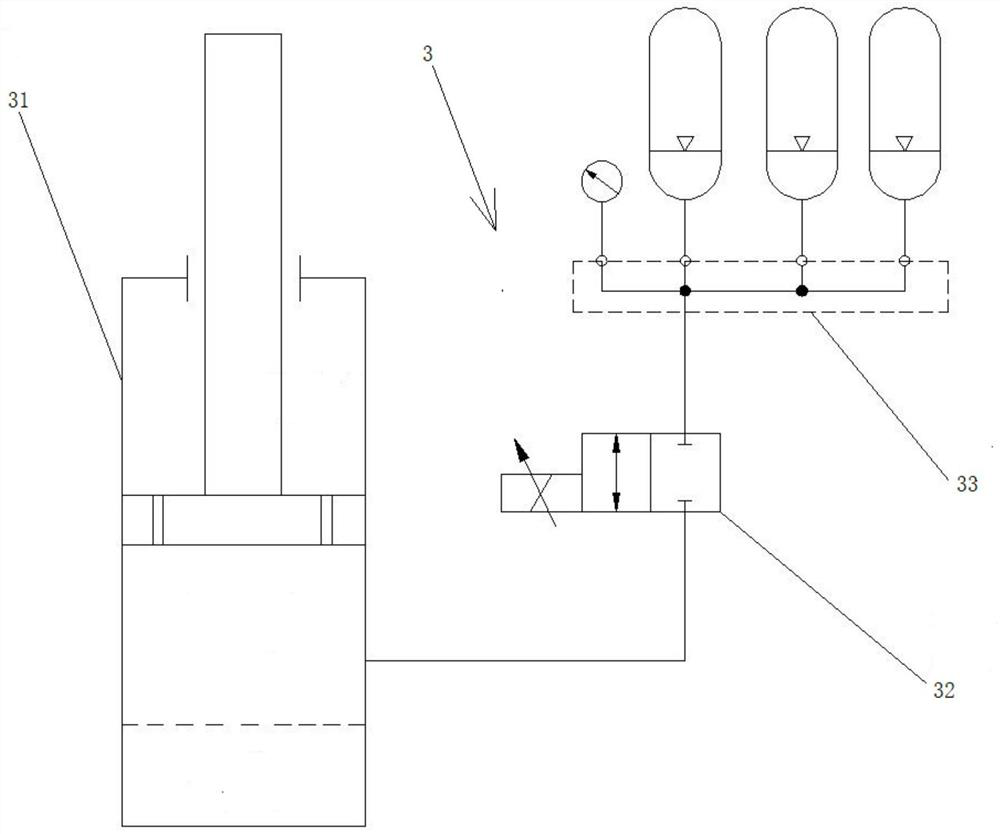

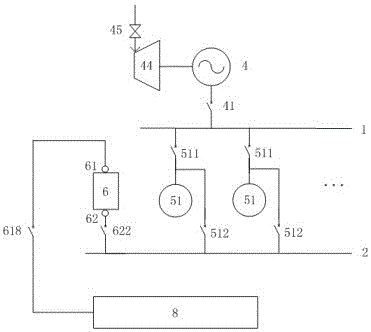

Electric energy converting-switching system and method and application thereof

PendingCN106849089AIncrease output powerReduce plant power consumptionSingle network parallel feeding arrangementsSingle ac network with different frequenciesAutomotive engineeringElectric energy

The invention discloses an electric energy converting-switching system and method applied to a thermal power plant. The frequency and / or voltage of at least one connection end can be adjusted through an electric energy transducer, and electric energy is controlled to flow among plant buses of different frequencies, or the electric energy can be controlled at different frequencies and can be controlled to flow among the plant buses of different frequencies, so that the throttling loss is reduced and even eliminated, the performance of a variable-frequency generating set is brought into full play, and the overall system efficiency is increased, thereby lowering the energy consumption and creating a greater economic benefit; meanwhile, a method of starting and switching through a motor of an auxiliary machine for a plant is improved, so that the flexibility of the overall running manner of the system is improved.

Owner:上海申能电力科技有限公司

Method and apparatus for designing and manufacturing electronic circuits subject to process variations

ActiveUS8578319B2Additional circuitryImprove the environmentDetecting faulty computer hardwareCAD circuit designMemory hierarchyEngineering

Methods and apparatus are described in which, at design-time a thorough analysis and exploration is performed to represent a multi-objective “optimal” trade-off point or points, e.g. on Pareto curves, for the relevant cost (C) and constraint criteria. More formally, the trade-off points may e.g. be positions on a hyper-surface in an N-dimensional Pareto search space. The axes represent the relevant cost (C), quality cost (Q) and restriction (R) criteria. Each of these working points is determined by positions for the system operation (determined during the design-time mapping) for a selected set of decision knobs (e.g. the way data are organized in a memory hierarchy). The C-Q-R values are determined based on design-time models that then have to be “average-case” values in order to avoid a too worst-case characterization. At processing time, first a run-time BIST manager performs a functional correctness test, i.e. checks all the modules based on stored self-test sequences and “equivalence checker” hardware. All units that fail are deactivated (so that they cannot consume any power any more) and with a flag the run-time trade-off controllers, e.g. Pareto controllers, are informed that these units are not available any more for the calibration or the mapping. At processing time, also a set of representative working points are “triggered” by an on-chip trade-off calibration manager, e.g. a Pareto calibration manager, that controls a set of monitors which measure the actual C-Q-R values and that calibrates the working points to their actual values. Especially timing monitors require a careful design because correctly calibrated absolute time scales have to be monitored.

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW)

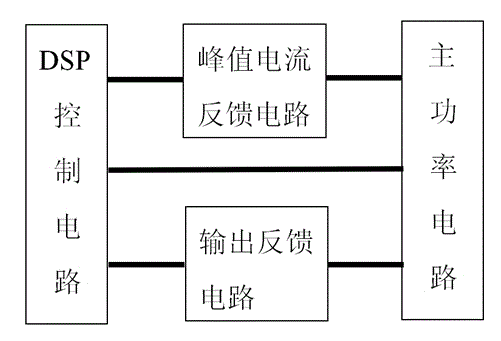

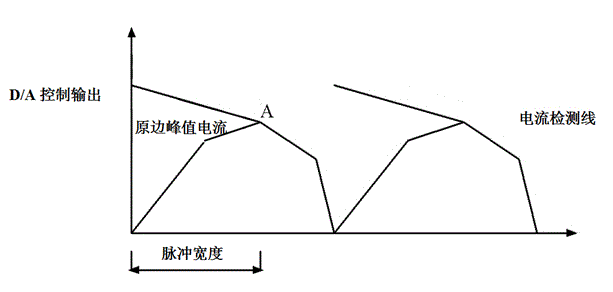

High-frequency power supply bias magnet suppression system based on DSP and control method

The invention discloses a high-frequency power supply bias magnet suppression system based on a DSP and a control method. The system comprises a DSP control circuit, a main power circuit, a peak current feedback circuit and an output feedback circuit, wherein the DSP control circuit is connected with the main power circuit, the peak current feedback circuit and the output feedback circuit, and the main power circuit is connected with the peak current feedback circuit and the output feedback circuit. The control method includes the steps that an analog comparator of the DSP control circuit and one D / A circuit form a peak control mode to control power supply output; the bias magnet phenomenon of a transformer is accurately detected and processed through the other D / A circuit and the analog comparator. By the adoption of the bias magnet suppression system and the control method, the bias magnet phenomenon can be detected in advance, controlled and eliminated, and the design allowance of the transformer is reduced.

Owner:SOUTH CHINA UNIV OF TECH

Method and apparatus for designing and manufacturing electronic circuits subject to leakage problems caused by temperature variations and/or aging

ActiveUS8578312B2Improved design environment and methodologyAdditional circuitryComputer controlCAD circuit designSystem requirementsTrade offs

First several possible working points are stored with different mappings to available modules. Each of these working points involves different trade-offs for important criteria related to performance and costs. At the design stage, these trade-off points for the criteria are not calibrated to the actual run-time conditions. Subsequently, based on actual values of the leakage criteria caused by temperature variations and / or ageing at given run-time conditions for (a subset of) the working points, it is possible to calibrate the trade-off curves and use a run-time controller to select the most suited working points afterward for an actual circuit. These active working points are selected to just meet the necessary system requirements on performance, while minimizing any of the important cost parameters.

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW)

Power amplifier

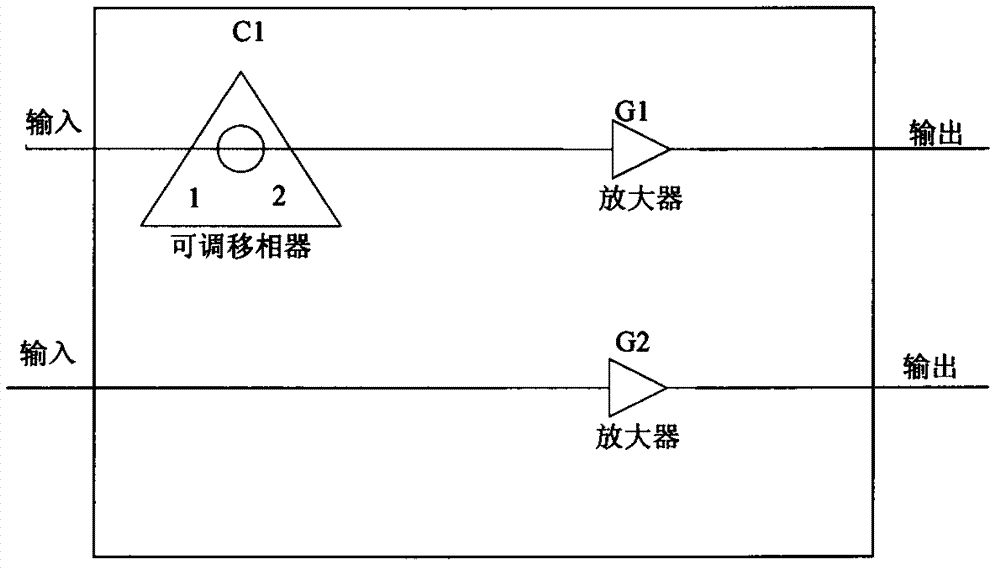

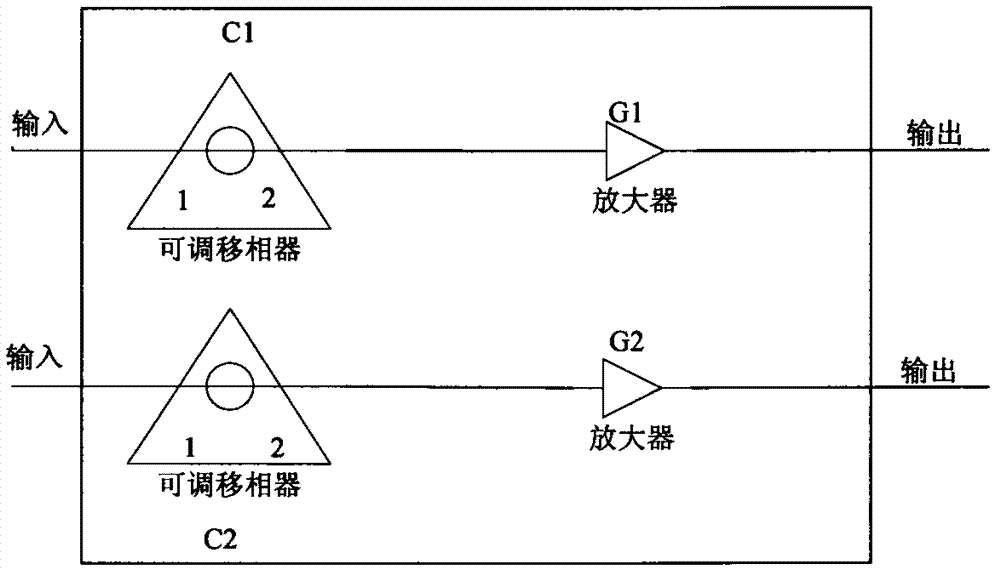

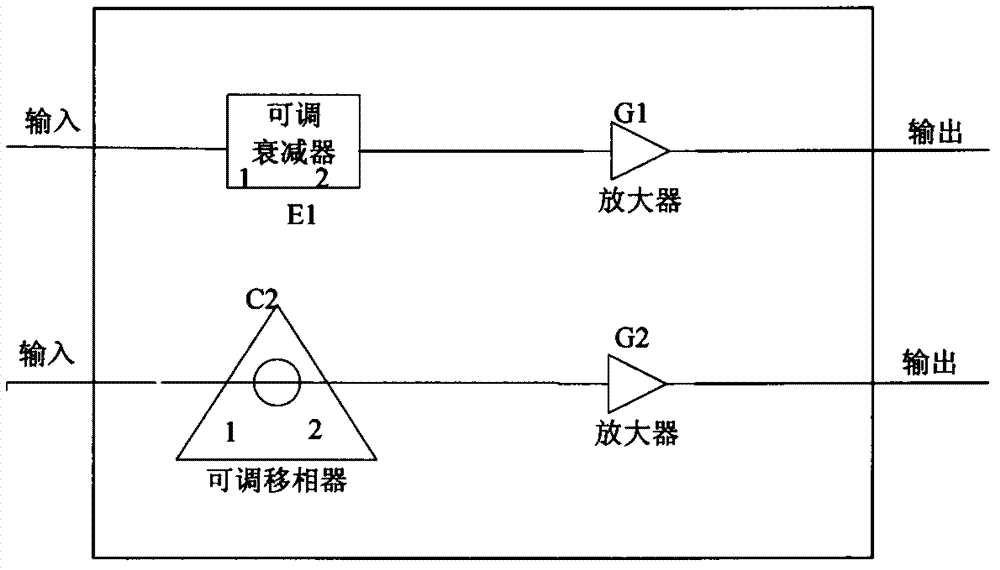

InactiveCN102957382AReduce phase deviationImprove yieldPower amplifiersTelecommunicationsAudio power amplifier

The invention provides a power amplifier comprising a plurality of power amplifying paths. Each power amplifying path comprises at least one amplifier, and at least one of the power amplifying paths is provided with at least one adjustable phase shifter. Compared with the prior art, the power amplifier has the advantages that phase error among the power amplifying paths is reduced by arranging the phase shifters on at least one of the power amplifying paths, affection resulted from production factors and devices themselves is greatly reduced, power synthesis efficiency is improved and yield rate of the power amplifier is increased.

Owner:ALCATEL LUCENT SHANGHAI BELL CO LTD

Nonvolatile semiconductor storage device

InactiveUS6914281B2Highly integratedReduce design marginTransistorSolid-state devicesFerroelectric thin filmsSemiconductor storage devices

In order to provide a nonvolatile semiconductor storage device designed to take off such existing restraint on the degree of freedom of device design as needed for the purpose of securing design margin, thus realizing a ferroelectric, nonvolatile storage device of high integration density, there is disclosed a capacitor using a ferroelectric thin film is provided, so that the apparent coercive electric field value in the operational guaranteed margin temperature of the nonvolatile semiconductor storage device when regarded as the voltage applied to the capacitor remains within the range of design margin of the nonvolatile semiconductor storage device at the coercive electric field value at the specified temperature, in which a metal oxide of a layer structure having the ferroelectric-to-normal dielectric phase transition point of 800° C. or higher may be used for the ferroelectric thin film.

Owner:SONY SEMICON SOLUTIONS CORP

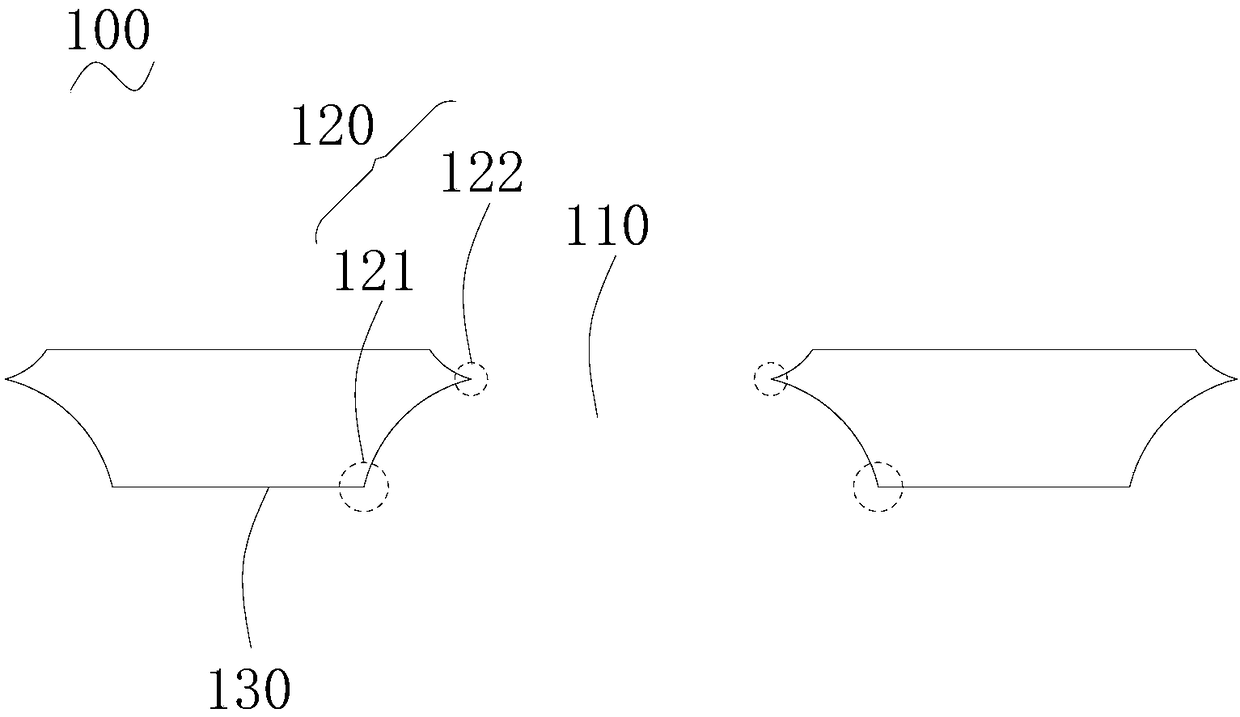

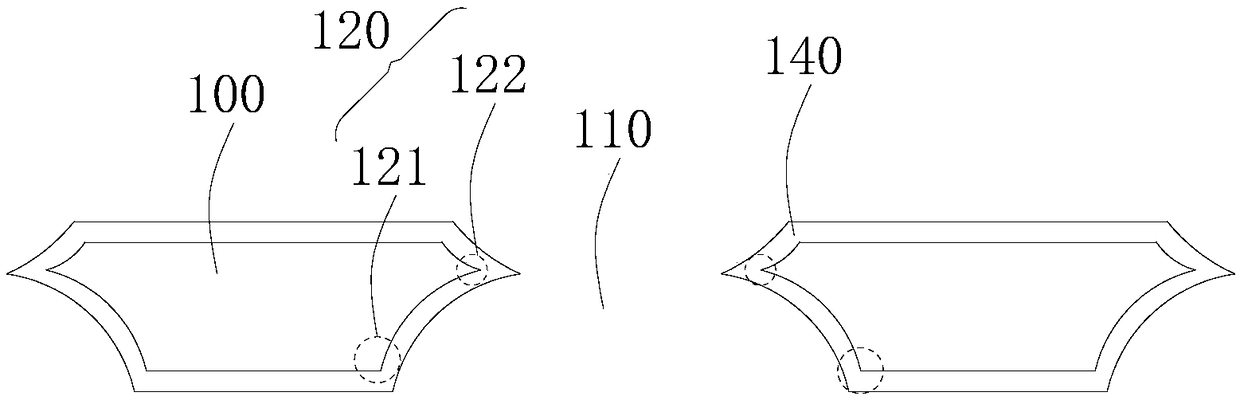

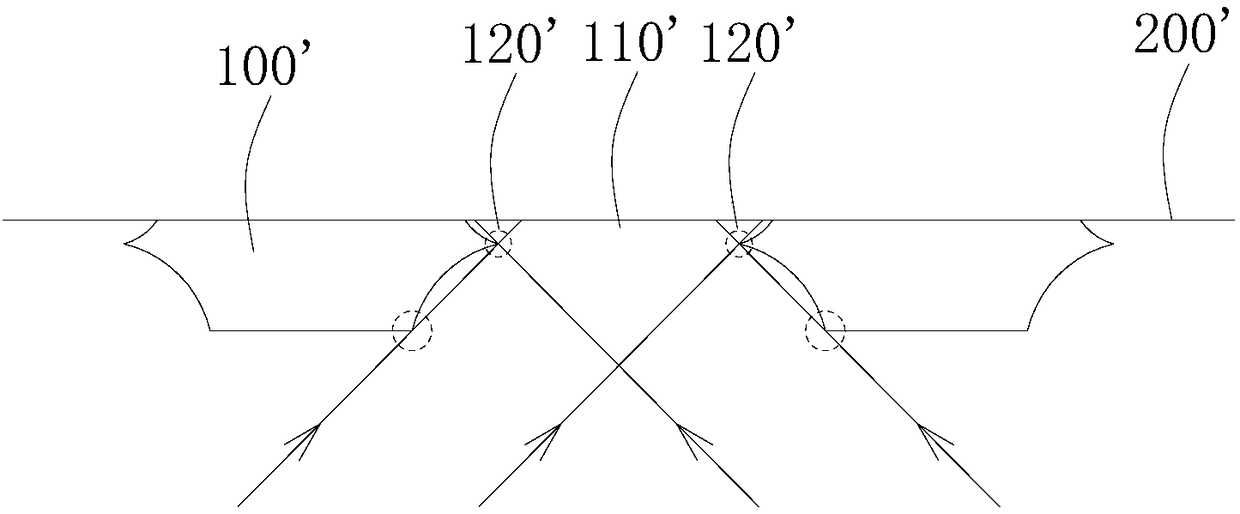

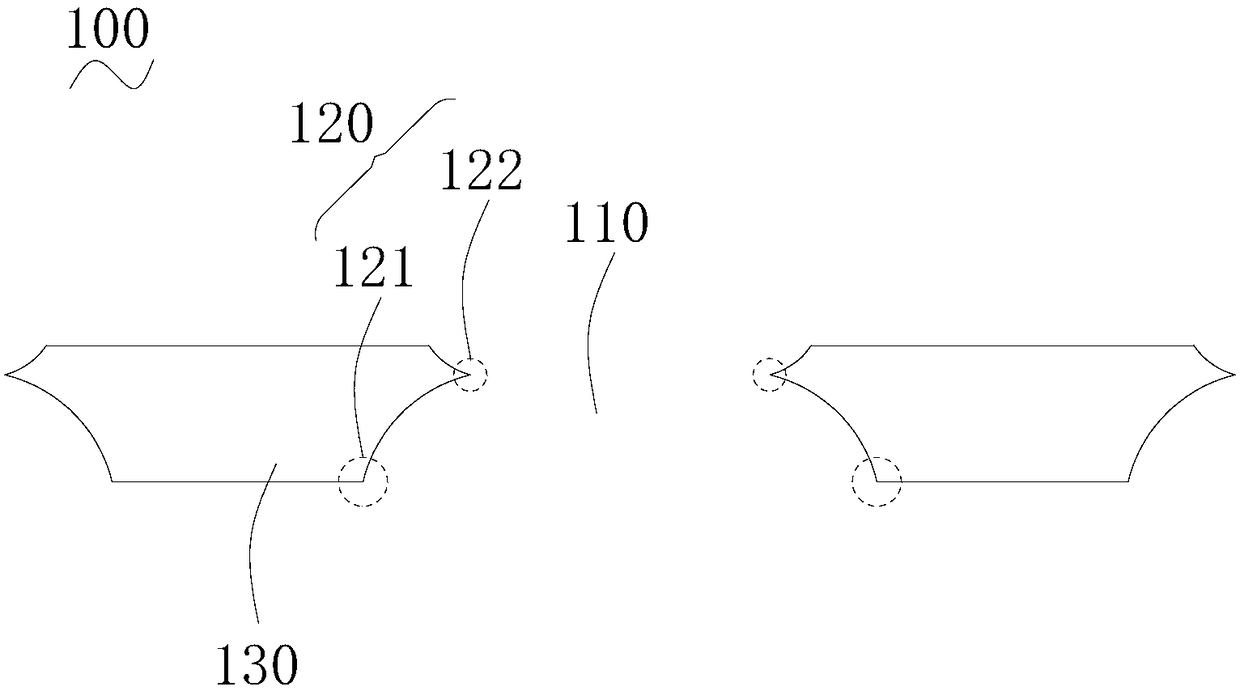

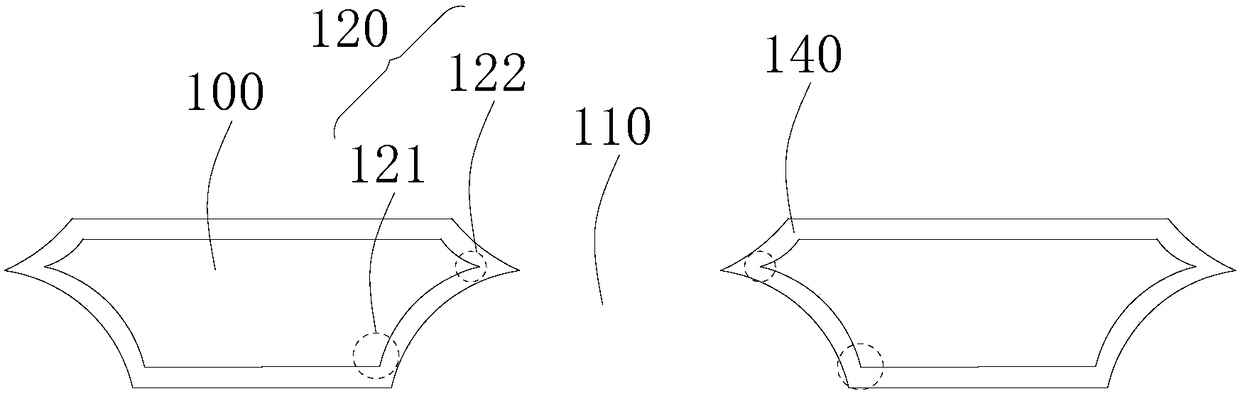

Post-processing method of mask plate and mask plate

InactiveCN108251794AReduce occlusionReduce design marginVacuum evaporation coatingSputtering coatingEvaporationEngineering

The invention relates to a post-processing method of a mask plate and the mask plate. The post-processing method of the mask plate comprises the following steps that the mask plate is provided, wherein the surface of the mask plate is provided with a convex portion; and at least one part of the convex portion of the mask plate is subjected to electrolytic treatment. By means of the post-processingmethod of the mask plate, the redundant convex portion located on the surface of the mask plate can be effectively removed or thinned. The mask plate is obtained by adopting the post-processing method. By reducing at least one part of the convex portion on the side wall face of an upper opening of the mask plate, blocked evaporation sources can be reduced, the evaporation effective area can be increased, the design margin can be reduced, the opening rate is increased, and high PPI product application is facilitated. In addition, burrs and corner affecting effects can be reduced.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

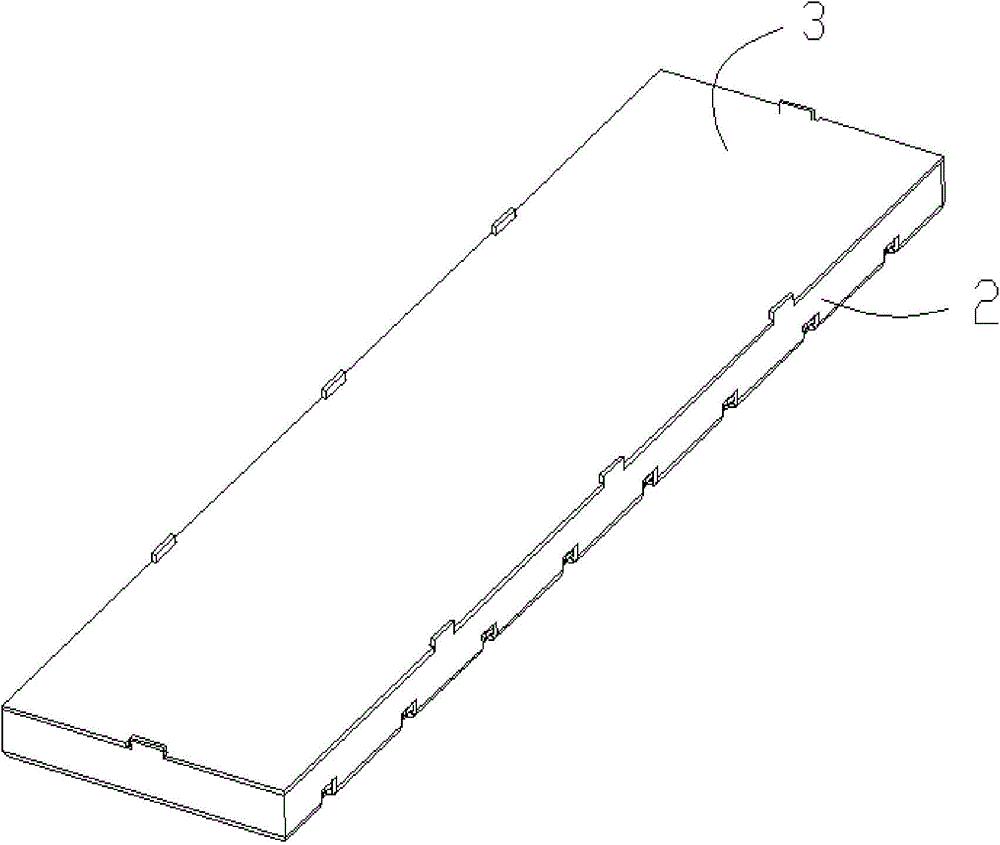

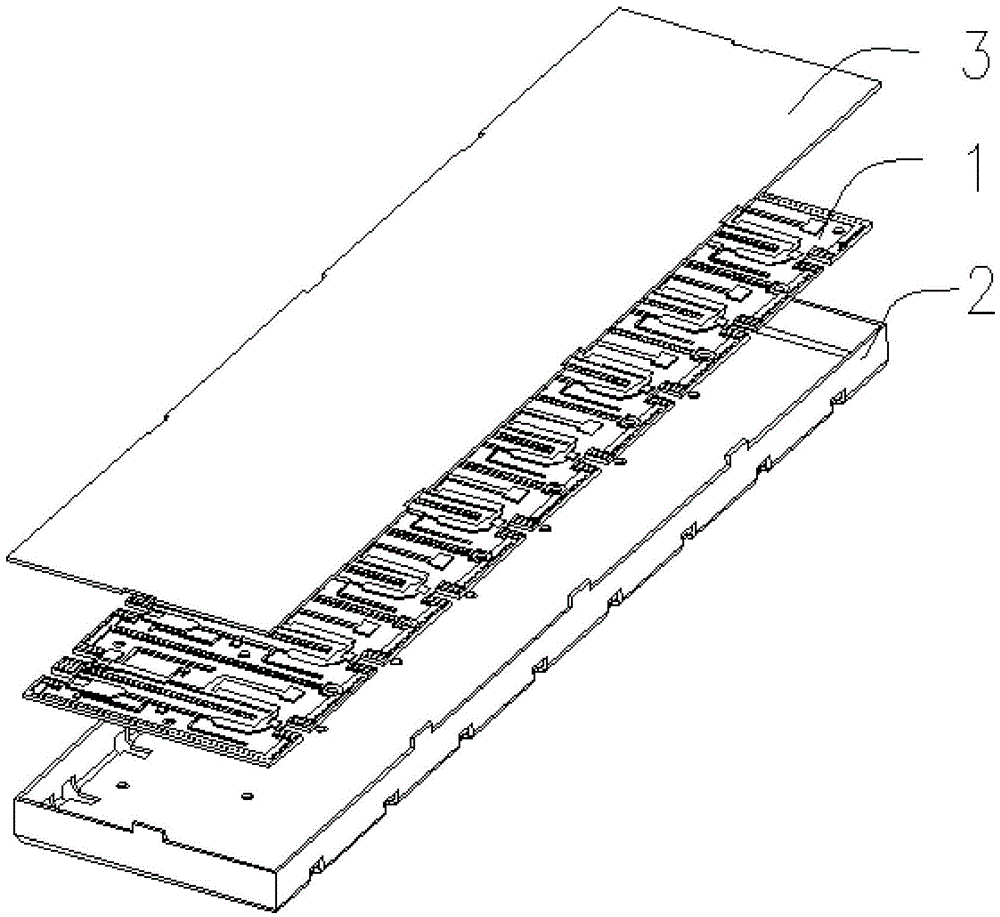

Integrated combiner

InactiveCN103956547AImprove assembly efficiencyImprove debugging efficiencyWaveguide type devicesMiniaturizationCenter frequency

The invention discloses an integrated combiner which comprises a circuit board and a metal frame, wherein the periphery of the metal frame is folded. The circuit board is provided with a plurality of combiner units which are integrally distributed side by side, each combiner unit is provided with an input port and an output port, and each combiner unit enables at least two filters to be output through the corresponding output port after the filters are combined. According to the integrated combiner, the multiple combiner units are designed in an integrated mode, miniaturization of the combiner is achieved, the size of an antenna is smaller, and the weight of the antenna is lower; due to the fact that the two filters are arranged in each combiner unit, the output end of each filter is provided with a microstrip line with the length 1 / 4 lambda the center frequency of a corresponding frequency band, influences between frequency bands are eliminated, the anti-interference capacity is strong, the design margin of each combiner unit is little, the whole combiner can be miniaturized, more space margin can be supplied to design of other components in the antenna of a base station, cost of the antenna is reduced, and large-scale assembling and debugging are facilitated.

Owner:JIANGSU JST RF SYST +2

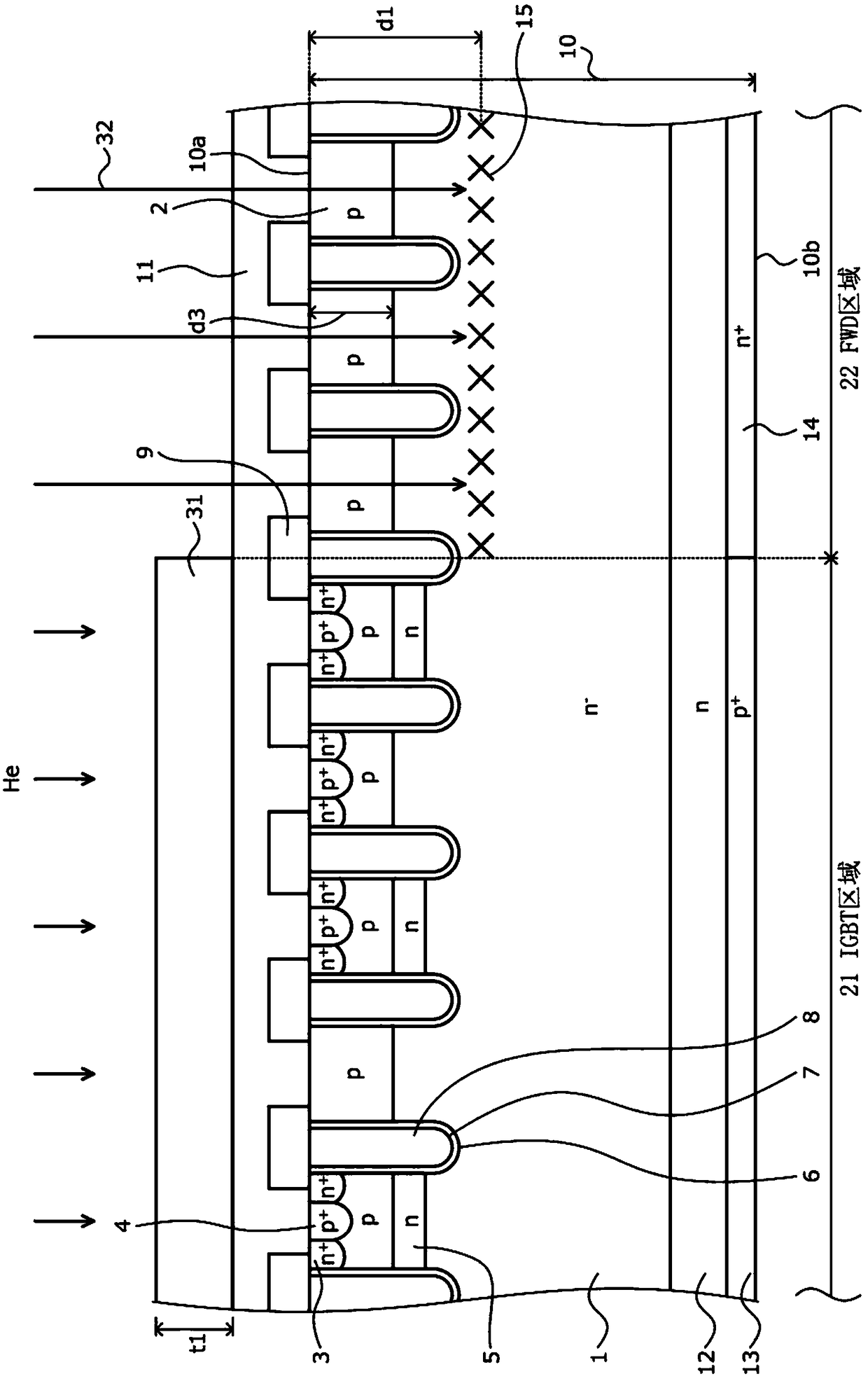

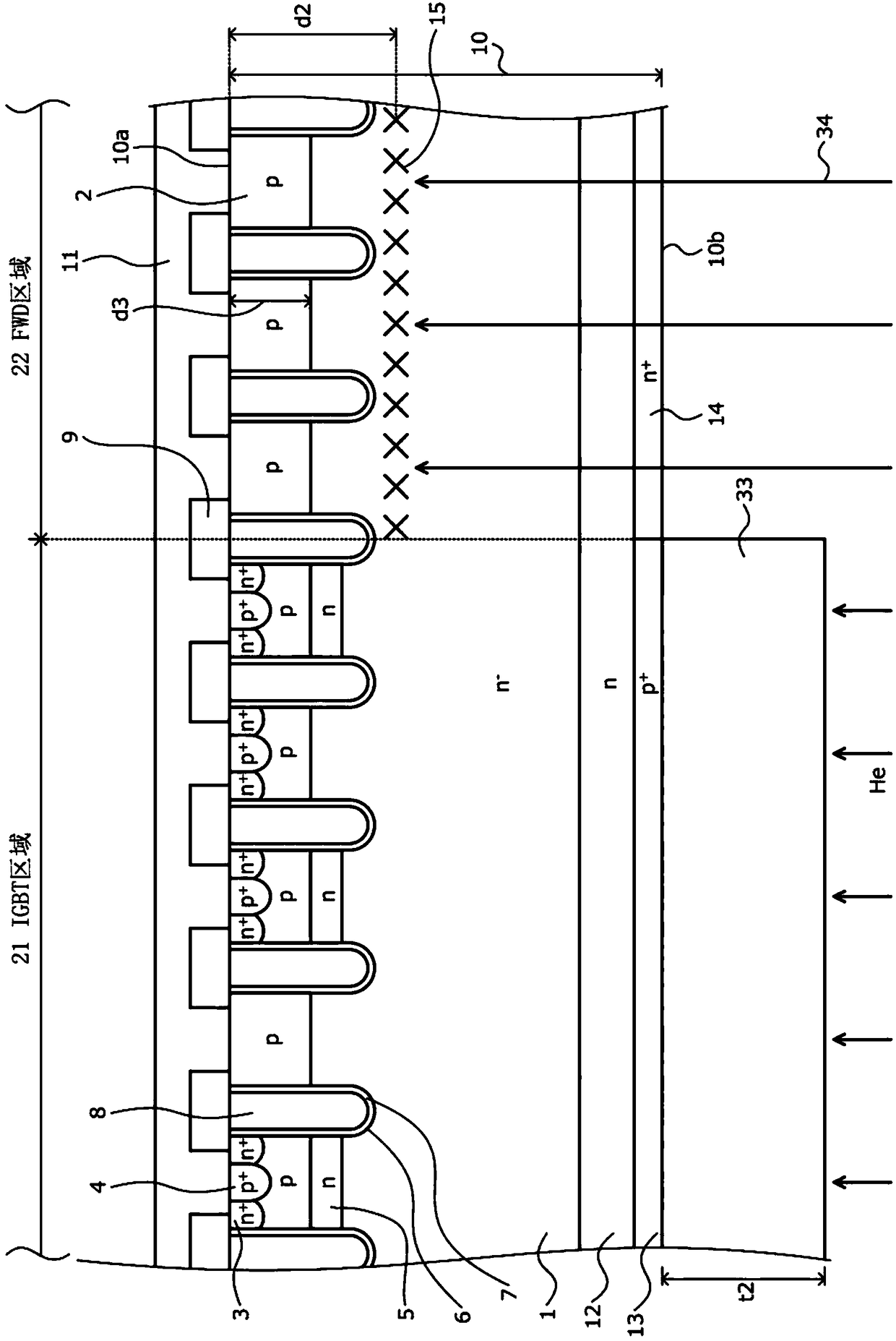

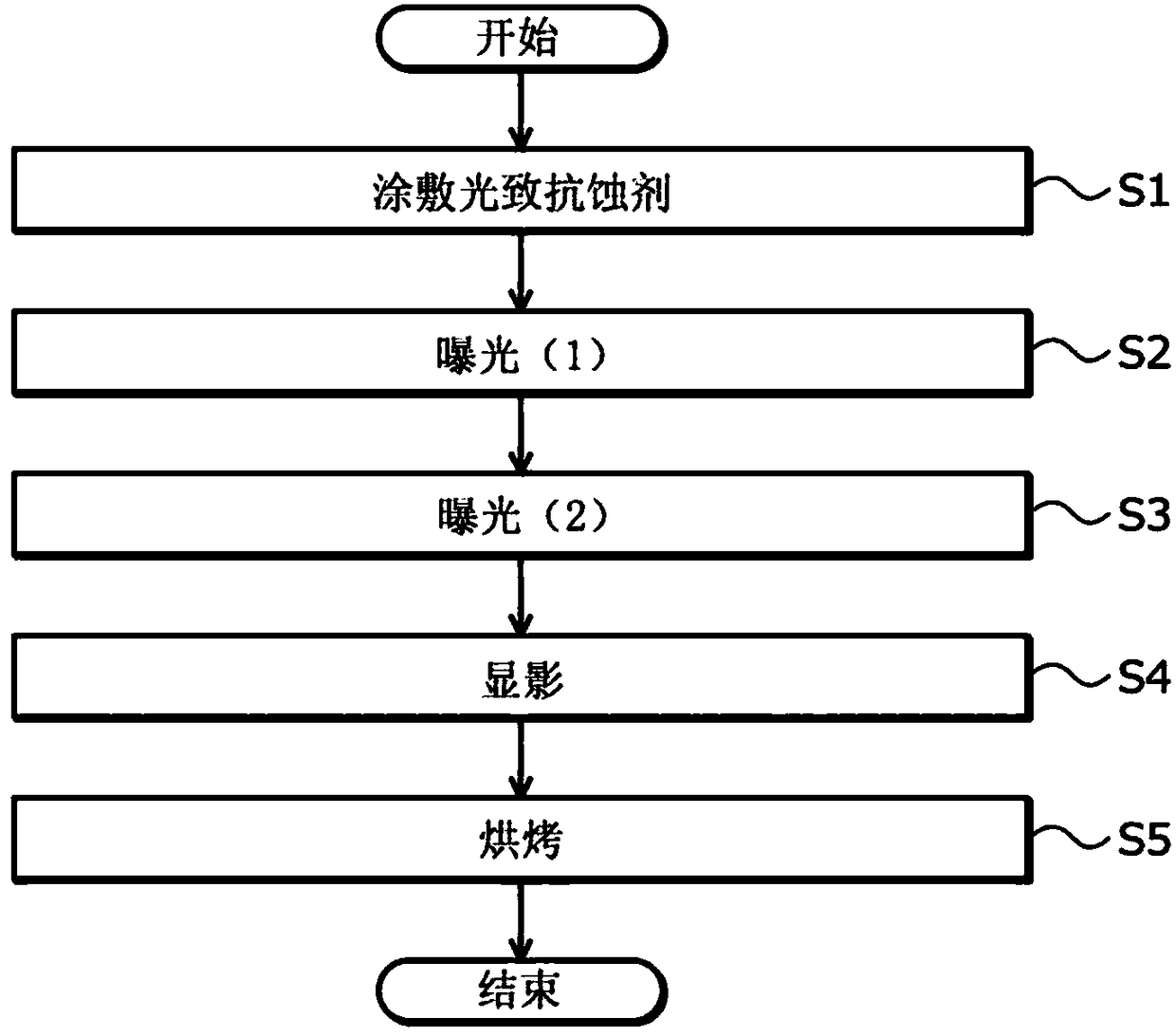

Method of manufacturing semiconductor device

ActiveCN108630532APrevent shape collapseReduce design marginSemiconductor/solid-state device manufacturingSemiconductor devicesWaferingDevice material

The present invention provides a method for manufacturing a semiconductor device capable of avoiding reduction of design margin caused for shape collapsing of an end portion of a slushing compound pattern when a photoresist is taken as a mask. The method of manufacturing a semiconductor device, includes the steps of: providing a semiconductor wafer (10), forming a photoresist film (31) on a main surface of the semiconductor wafer, forming a first mask pattern and a second mask pattern on the photoresist film (31), selectively removing portions of the photoresist film (31) according to the first and second mask patterns, to respectively form a first opening and a second opening in the photoresist film (31), a position of the second opening differing from that of the first opening, and performing ion implantation of an impurity into the semiconductor wafer (10), using the photoresist film (31) having the first and second openings formed therein as a mask (31).

Owner:FUJI ELECTRIC CO LTD

Operation method of nuclear power plant

ActiveUS20100170246A1Increase thermal powerIncrease flow rateNuclear energy generationSteam useNuclear reactorNuclear power

In a nuclear power plant, thermal power in a second operation cycle of a nuclear reactor is uprated from thermal power in a first operation cycle preceding the second operation cycle by at least one operation cycle. A proportion of steam extracted from a steam system and introduced to a feedwater heater, which is in particular extracted from an intermediate point and an outlet of a high pressure turbine, with respect to a flow rate of main steam, is reduced in the second operation cycle from that in the first operation cycle such that the temperature of feedwater discharged from the feedwater heater is lowered by 1° C. to 40° C. in the second operation cycle.

Owner:HITACHI-GE NUCLEAR ENERGY LTD

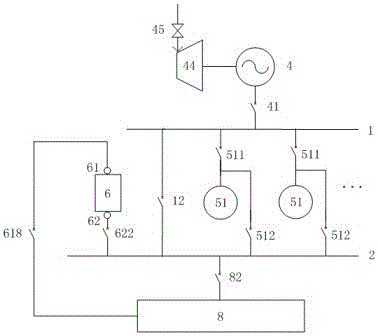

Electric energy conversion and switching system for multiple buses

PendingCN106887992AIncrease output powerReduce plant power consumptionAC motor controlConvertersPower station

The invention provides an electric energy conversion and switching system for multiple buses in a thermal power plant. The frequency and / or the voltage of at least one connection end can be adjusted by an electric energy converter. Meanwhile, the electric energy is controlled to flow among the buses of the thermal power plant, wherein the buses are different in frequency. Or, the electric energy is controlled to flow among the buses of the thermal power plant, wherein the buses are the same in frequency or are different in frequency. Moreover, the throttling loss is reduced and even eliminated. The performance of a frequency-conversion generator set is fully played and the overall efficiency of the system is improved. As a result, the energy consumption is reduced and higher economic benefits are created. Meanwhile, a bus is divided into a plurality of segments for power supply, so that the running safety and the running reliability of the auxiliary machine of the frequency-conversion system are improved. In addition, through improving the motor starting and switching method of the auxiliary machine of the thermal power plant, the flexibility of the overall operation mode of the system is improved.

Owner:上海申能电力科技有限公司

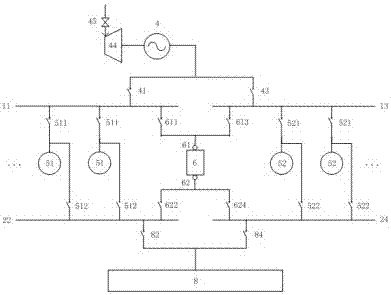

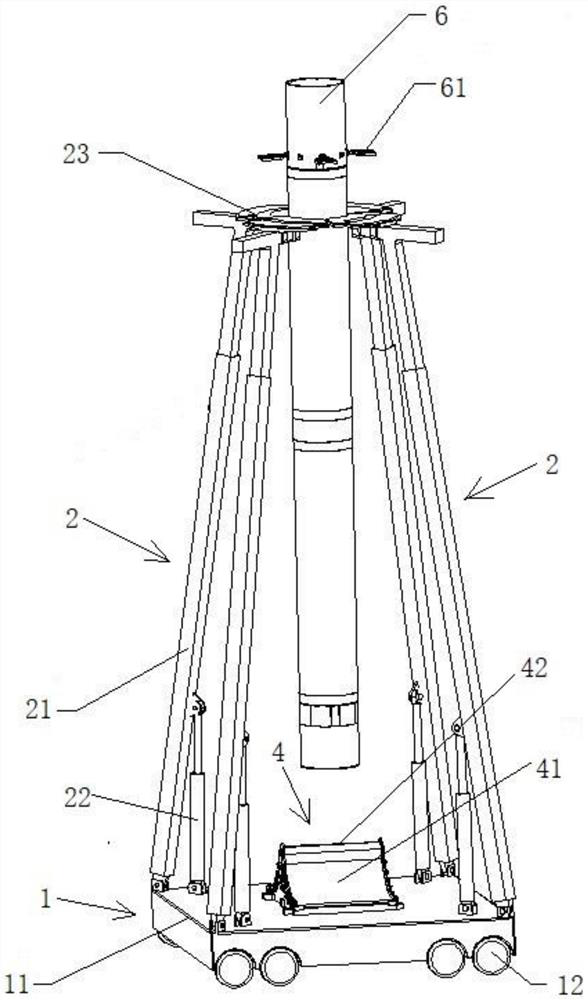

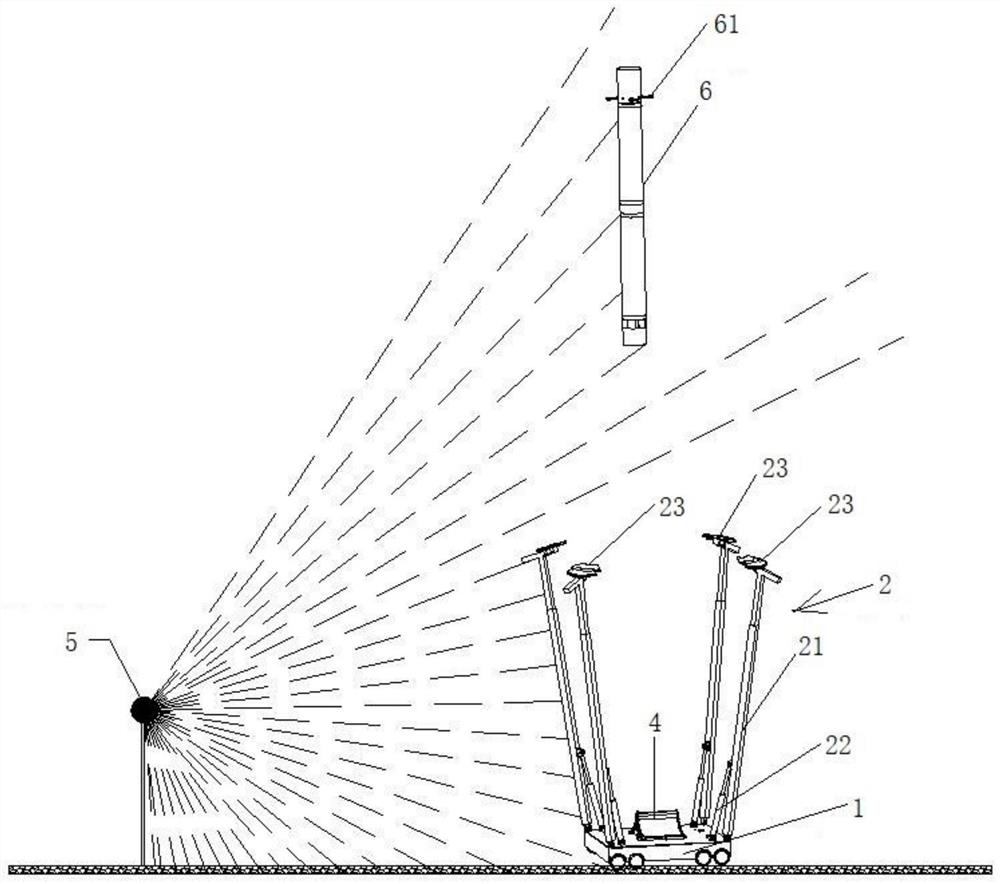

Ground recovery platform capable of repeatedly using carrier rocket

PendingCN114459297AReduce dead loadReduce complexitySelf-propelled projectilesDrive wheelControl system

The invention relates to a reusable ground recovery platform for a carrier rocket. The reusable ground recovery platform comprises a movable chassis, a capturing device and a recovery buffer device, the mobile chassis comprises a chassis framework, omni-directional driving wheels and a chassis control system, the at least three sets of capturing devices are arranged in a nonlinear mode, each capturing device comprises a recycling embracing arm, a first telescopic power piece, a capturing clamping table and a capturing control system, and the recycling buffering device comprises an oil gas buffer and a buffering energy storage control system. And the oil gas buffer is mounted in the recovery holding arm and is controlled by the buffer energy storage control system. The soft landing method has the following predictable technical effects that soft landing of the reusable carrier rocket can be achieved, a landing buffer system does not need to be installed on the reusable carrier rocket, the invalid load when the rocket takes off is reduced, and the complexity and cost of a rocket system are reduced.

Owner:AEROSPACE SCI & IND KET TECH CO LTD

Post-processing method of mask plates and mask plates

InactiveCN108330437AReduce occlusionReduce design marginVacuum evaporation coatingSolid-state devicesEvaporationEngineering

The invention relates to a post-processing method of mask plates and the mask plates. The post-processing method of the mask plate comprises the following steps that the mask plates are provided, andthe surfaces of the mask plates are provided with raised parts; and at least a part of the raised parts are subjected to chemical grinding treatment. The post-processing method of the mask plates caneffectively remove or thin unanticipated and spare raised parts on the mask surfaces. The mask plates are manufactured and processed by the post-processing method of the mask plates, by reducing at least a part of the raised parts located on the side wall faces of the upper openings of the mask plates, the occlusion on evaporation source can be reduced, the effective area of evaporation can be increased, the reduction of the design margin is facilitated, the aperture opening ratio is increased, and the application of high PPI products is facilitated. In addition, burr and corner influence effects are further reduced.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

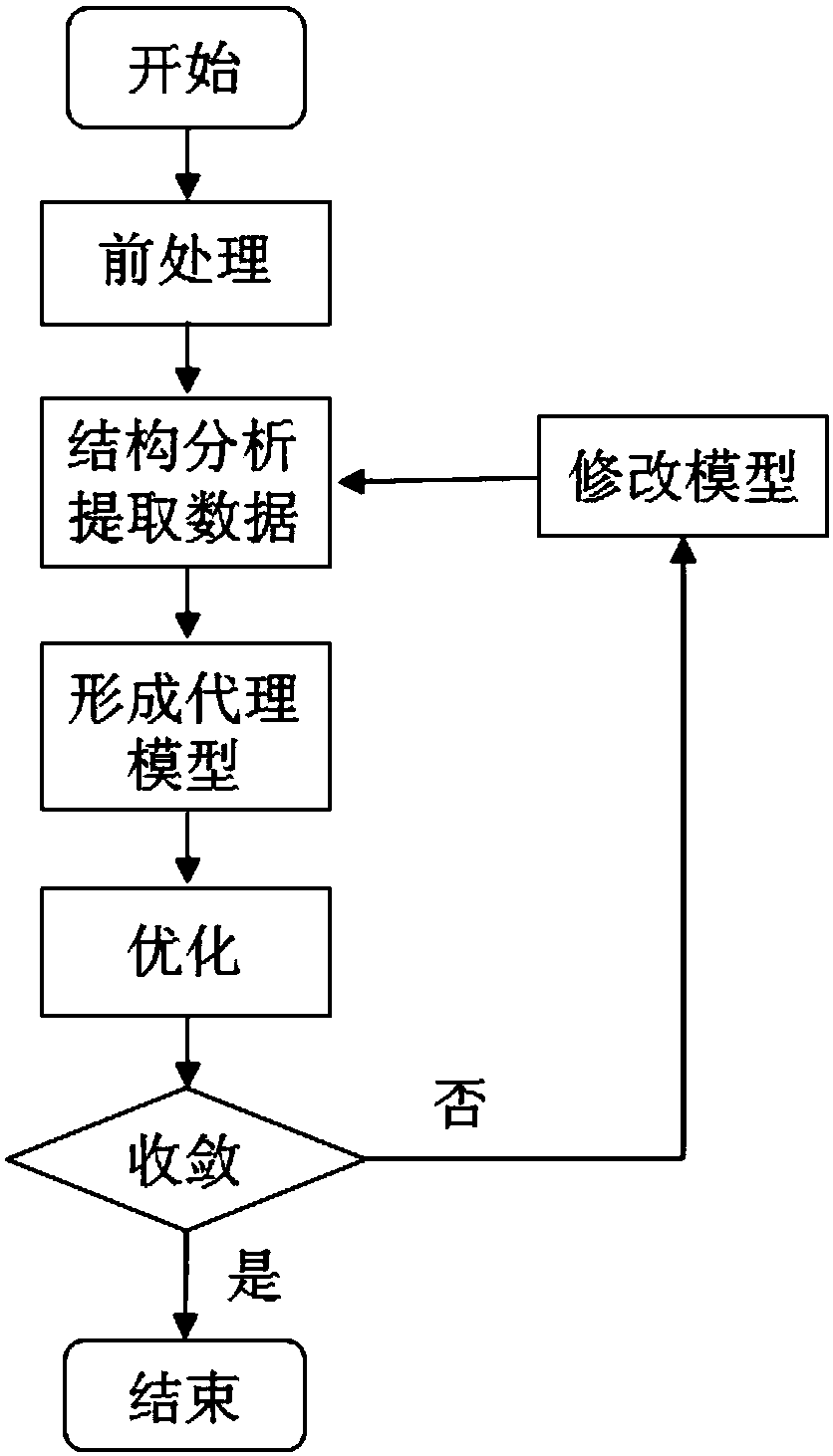

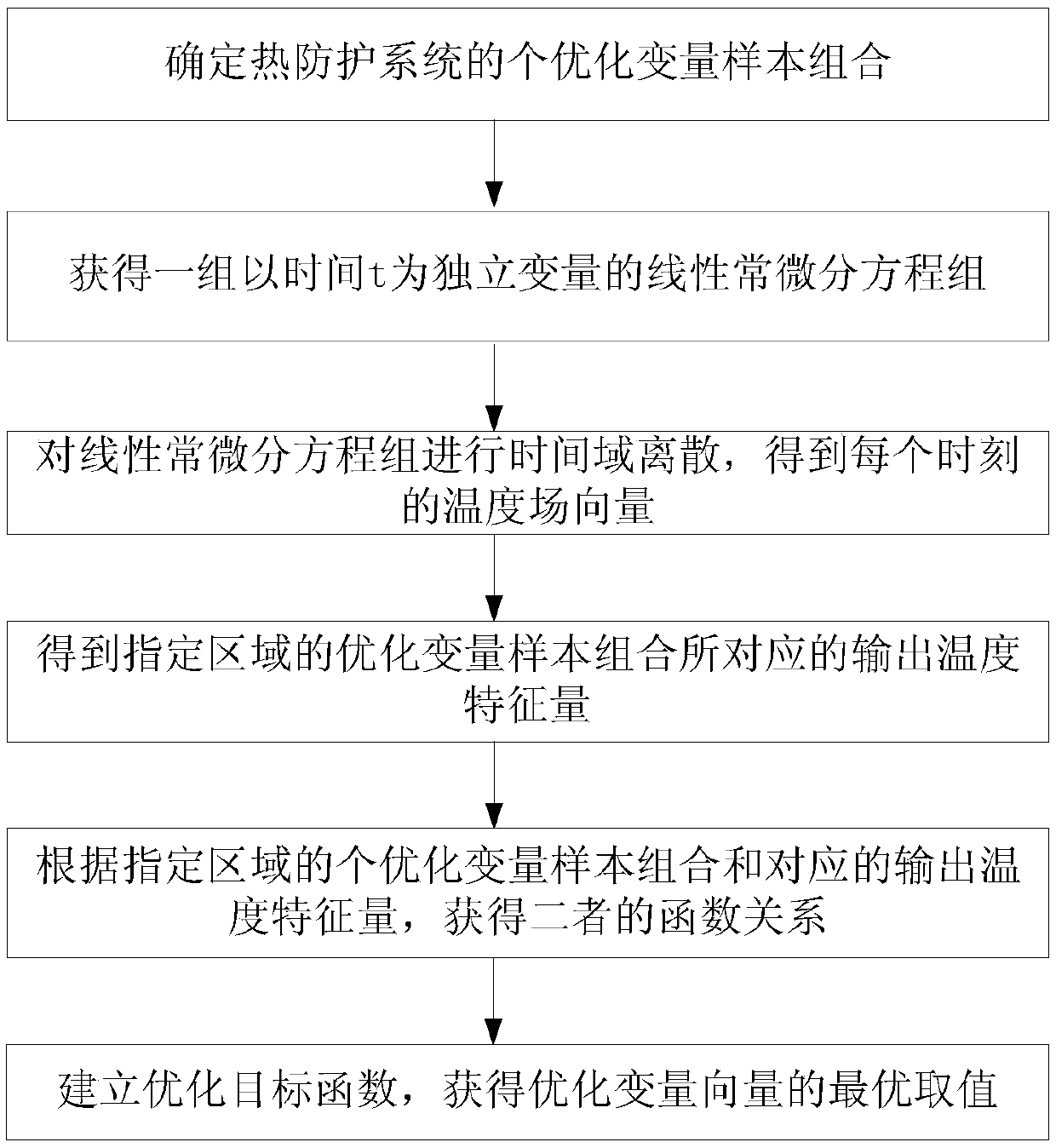

A thermal protection system optimization design method and system based on an agent model

PendingCN109598059AReduce design marginReduce weightGeometric CADSustainable transportationLinear ordinary differential equationDesign systems

The invention relates to a thermal protection system optimization design method and module based on an agent model, and the method comprises the steps: carrying out the finite element analysis on thebasis of a small sample, carrying out the fitting of a response surface model, carrying out the large optimization analysis on the response surface model, greatly reducing the calculation amount, andimproving the efficiency. Meanwhile, a linear constant differential equation set of the thermal protection analysis model is solved by adopting a time integration method, so that the resolving time issaved; According to the invention, geometric dimensions are also considered; A thermal analysis model is established under the influence of a plurality of optimization variables of the density, the specific heat capacity, the heat conductivity and the surface radiance of the thermal protection system on thermal protection, so that the thermal protection system optimization design has higher precision, and a more scientific and accurate basis is provided for the thermal protection system design of the hypersonic flight vehicle; In addition, the method effectively reduces the design allowance of the thermal protection system, reduces the weight of the thermal protection system and reduces the power consumption of the aircraft.

Owner:CHINA ACAD OF LAUNCH VEHICLE TECH

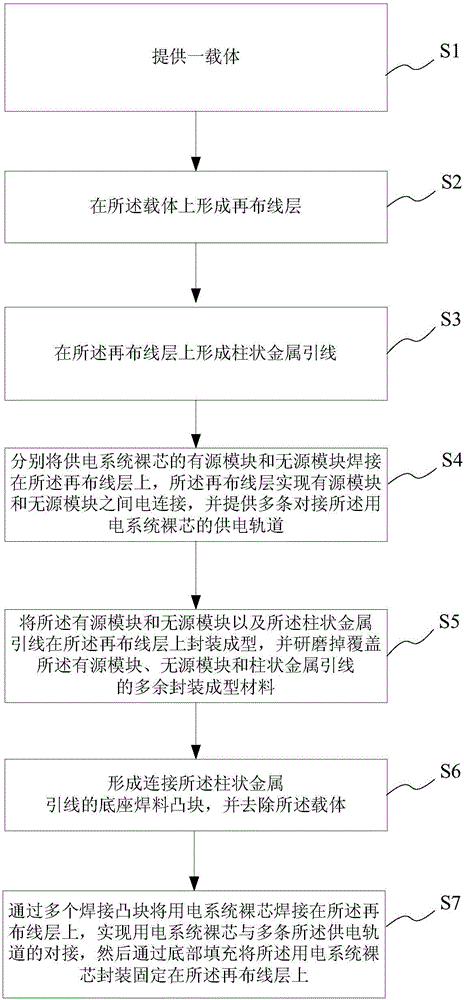

Package method of integrated power supply system package element

InactiveCN106783649AEliminate parasitic resistanceSolve processing problemsSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringThree-dimensional integrated circuit

The invention provides a package method of an integrated power supply system package element. The method includes the following steps that a carrier is provided; a re-wiring layer is formed on the carrier; a columnar metal lead is formed on the re-wiring layer; an active module and a passive module of a power supply system bare core are welded to the re-wiring layer; the active module, the passive module and the columnar metal lead are packaged and formed on the re-wiring layer, and redundant packaging and forming materials for covering the active module, the passive module and the columnar metal lead are removed through grinding; a base solder protruding block connected with the columnar metal lead is formed, and the carrier is removed; a power consumption system bare core is welded to the re-wiring layer, and then the power consumption system bare core is packaged and fixed to the re-wiring layer through bottom filling. By means of the three-dimensional chip stacking technology, a power supply system is directly integrated on the lower portion of the power consumption system bare core, power transmission efficiency is improved, and the number of different usable voltage rails is increased.

Owner:SJ SEMICON JIANGYIN CORP

Novel system and method for electric energy conversion and motor switching and application

PendingCN106849091AIncrease output powerReduce plant power consumptionSingle network parallel feeding arrangementsSingle ac network with different frequenciesElectric energyPower station

The invention relates to a novel system and a method for electric energy conversion and motor switching in a thermal power plant. The method has the advantages that the frequency and / or voltage of at least one connecting end can be adjusted by an electric energy converter, and the electric energy is controlled to flow between auxiliary buses of different frequency, or the electric energy is controlled to flow between the auxiliary buses of the same frequency and different frequency, so that the throttling loss is decreased and even eliminated, the property of a variable-frequency power generator is fully played, and the efficiency of whole system is improved, thereby decreasing the energy consumption, and creating larger economic benefit; the electric connecting relationship of the electric energy converter is increased, more motor starting and switching methods of the auxiliary units with more variety are improved and realized, and the flexibility in running type of the whole system is improved.

Owner:上海申能电力科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com