Shell-and-tube heat exchanger and method for machining plate holes in shell-and-tube heat exchanger

A technology of shell-and-tube heat exchangers and plate holes, which is applied in the field of heat transfer, can solve problems such as unfavorable shell-side fluid uniform flow, achieve accurate prediction of heat transfer performance and stress distribution, promote uniform flow, and reduce modeling difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

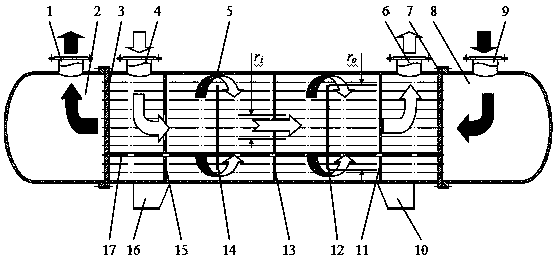

[0051] Design a heat exchanger, which is mainly composed of shell, tube sheet, heat exchange tube, tube box, baffle plate, etc. The material is not limited, such as figure 1 shown. The tube-side fluid enters from the tube-side inlet nozzle 9 on the right tube box 8, flows through the heat exchange tube bundle 17 from left to right, collects in the left tube box 2, and is discharged from the tube-side outlet nozzle 1; the shell-side fluid flows from the cylindrical The shell side inlet joint 4 of the cylinder 5 enters, and under the action of the baffle, the shell side flows radially, forming a cross flow with the tube side fluid, and finally discharges through the shell side inlet joint 7 of the cylinder 5 .

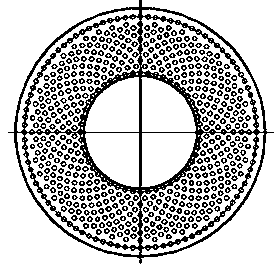

[0052] The heat exchange tube bundle is fixed by the left tube plate 3 and the right tube plate 7 welded to the cylinder body 5, and passes through each baffle. Both the tube sheet and the baffle (ring-shaped and disc-shaped) have plate holes consistent with the outer d...

Embodiment 2

[0058] According to the plate hole arrangement principle of the present invention, the following steps are adopted to determine the position of the plate holes.

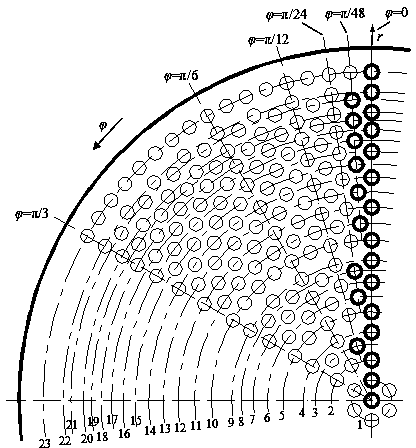

[0059] ①As attached figure 2 As shown, a polar coordinate system is established, the origin of the coordinate system is placed at the center of the tube sheet, the radial coordinate is r, and the circumferential coordinate is . Set the first plate hole in the center of the tube plate.

[0060] ② Determine the minimum spacing d of the plate holes s . With (r=0) as the center, d s Make the first concentric circle for the radius, and set 6 plate holes evenly on the concentric circle according to the principle (3), and the center of one of the plate holes is located at superior. The spacing of these 6 plate holes satisfies d s ≥1.25d requirement.

[0061] ③According to the method for determining the radius of concentric circles, the radius of the second concentric circle is calculated to be 2d s , 6 plate hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com