FCM (full ceramic microcapsulated) fuel effective multigroup cross section acquiring method

A cross-section and fuel technology, applied in the field of nuclear reactor core and nuclear reactor physical calculation, can solve the problems of low calculation efficiency, calculation deviation, inability to homogenize particles and substrates, etc., and achieves less memory storage, faster calculation, and reduced Effects of Design Margins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0079] A method for obtaining the effective multi-group section of FCM fuel of the present invention comprises the following steps:

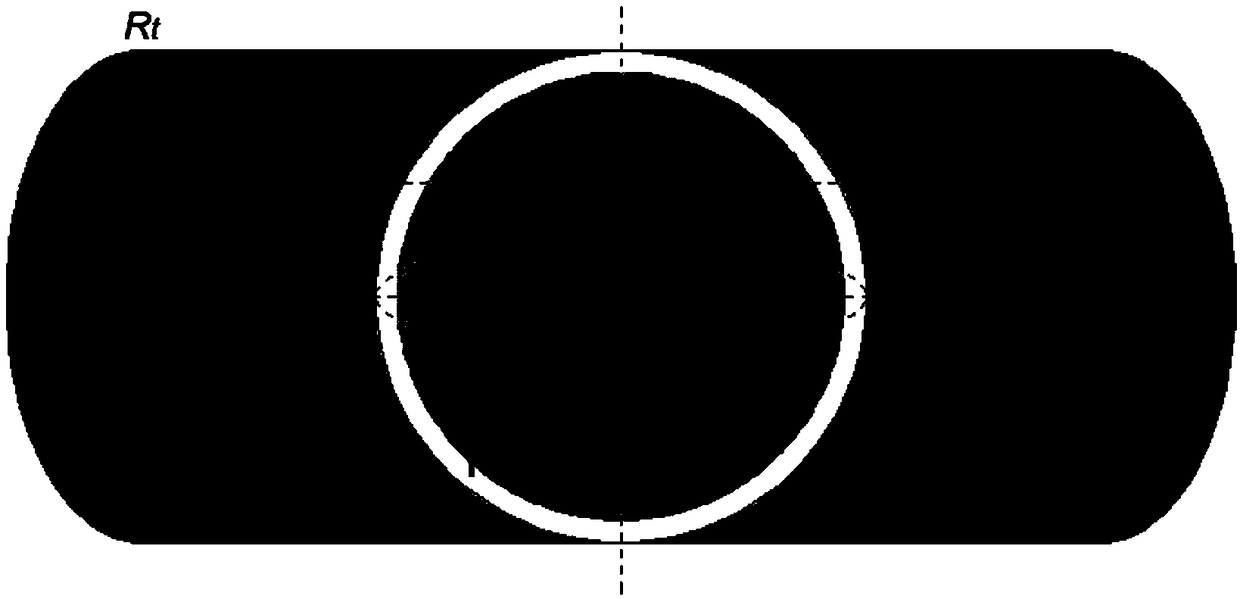

[0080] Step 1: Construct a one-dimensional spherical model with TRISO particles inside and matrix material outside. The radius of the matrix material can be calculated by formula (1); in the resonance energy section, solve the ultrafine group shown in formula (2) for this model The moderation equation is used to obtain the ultrafine group flux in the TRISO particle and the matrix; then the defect factor of the ultrafine group in the TRISO particle and the matrix can be obtained from the formula (3);

[0081]

[0082] in,

[0083] R m - the radius of the matrix material;

[0084] R t - the radius of the TRISO particle;

[0085] F - the filling rate of TRISO particles;

[0086]

[0087] in,

[0088] ∑ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com