Synthesis ammonia and methanol co-production method and device for improving methanol productivity

A technology for synthesizing ammonia and methanol, applied in chemical instruments and methods, ammonia preparation/separation, hydroxyl compound preparation, etc., can solve the problems of reduced methanol production capacity, inability to recycle, unstable operation, etc., so as to reduce air discharge and load. , the effect of improving methanol production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

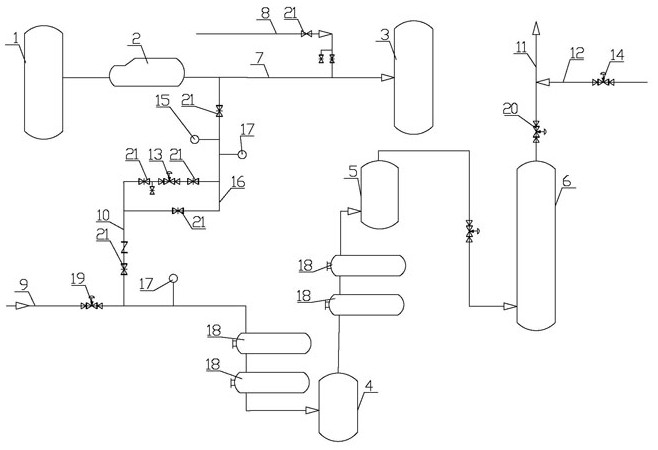

[0023] Embodiment 1: as attached figure 1 As shown, the method for synthesizing ammonia to co-produce methanol for improving methanol production capacity is carried out as follows: the shift gas generated by the first shift furnace 1 is divided into two streams, one stream of shift gas and high nitrogen tail gas (containing 30% nitrogen ) into the second shift furnace 3 together, and another stream of shifted gas merges with unshifted gas to form the pre-hydrogen mixed gas. After the first heat exchange and cooling, the pre-hydrogen mixed gas is separated by the water separation tank 4 The saturated water of the mixed gas with hydrogen is then cooled to normal temperature through the second heat exchange, and the ammonia in the mixed gas with hydrogen is removed through the ammonia washing tower 5, and the sulfide and carbon dioxide are removed through the unshifted gas washing tower 6 to obtain purified gas , after the purified gas is combined with the post-hydrogen gas from ...

Embodiment 2

[0026] Embodiment 2: as attached figure 1 As shown, the device for implementing the method for synthesizing ammonia and co-producing methanol described in Example 1 for improving methanol production capacity includes a first shift furnace 1, a medium-pressure waste heat boiler 2, a second shift furnace 3, a first heat exchange device, water The separation tank 4 and the unconverted gas scrubber 6, the converted gas outlet of the first shift furnace 1 communicates with the inlet of the medium-pressure waste heat boiler 2, and the gas outlet of the medium-pressure waste heat boiler 2 communicates with the inlet of the second shift furnace 3 The end is connected through the conversion gas pipeline 7, and the conversion gas pipeline 7 is connected with the liquid nitrogen washing recovery gas pipeline 8, and the high temperature end inlet of the first heat exchange device is connected with the untransformed gas pipeline 9, and the gas outlet of the medium pressure waste heat boiler...

Embodiment 3

[0039] Embodiment 3: the operating process of the device described in embodiment 2 is as follows:

[0040] (1) Unconverted system (including unconverted gas pipeline 9) and unconverted gas scrubber 6 depressurization: close unconverted gas control valve 19, open large low-temperature methanol to wash unconverted purified gas (that is, unconverted gas scrubber 6 ) outlet of the purified gas control valve 20 to reduce the untransformed system pressure to about 5.4MPa (that is, the outlet pressure of the water separation tank 4 is about 0.1MPa lower than the inlet pressure of the second conversion furnace 3); pay attention to the post-hydrogen distribution pipeline during depressurization 12 of the hydrogen dosing amount, make adjustments to maintain a stable flow;

[0041] (2) Pipeline pressure boost: close the front hydrogen distribution flow control valve 13 and the valve 21 of the bypass pipeline 16, slowly open the front gas distribution shaker valve (reserved valve), and pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com