A pressure swing adsorption decarburization method and equipment capable of realizing adjustable alcohol-ammonia ratio

A technology of pressure swing adsorption and alcohol-ammonia ratio, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles. It can solve problems such as high installation and operation costs, and equipment that cannot meet the market fluctuations of methanol and synthetic ammonia, and achieve coal saving. The effect is remarkable, the effective gas yield is improved, and the effect of reducing the venting amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 【Major equipment】

[0028] The existing one-stage pressure swing adsorption decarburization process is refitted into the equipment of the invention.

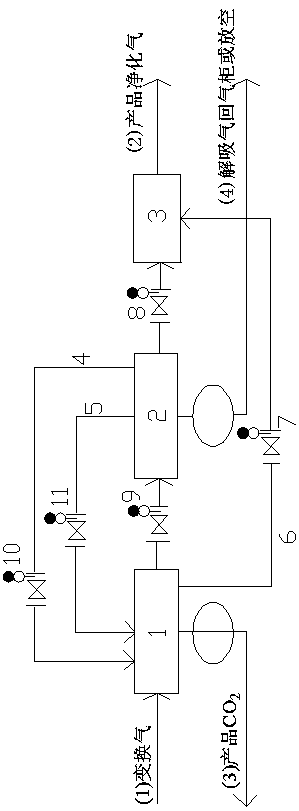

[0029] as attached figure 1 As shown, the PSA decarburization equipment capable of adjusting the ratio of alcohol to ammonia in the present invention is mainly composed of a first-stage PSA mechanism 1 , a second-stage PSA mechanism 2 , and a fine desulfurization mechanism 3 .

[0030] The first-stage pressure swing adsorption mechanism 1, the second-stage pressure swing adsorption mechanism 2 and the fine desulfurization mechanism 3 are sequentially connected in series through pipelines. Between the first-stage pressure swing adsorption mechanism 1 and the second-stage pressure swing adsorption mechanism 2, a primary parallel air release pipeline 4 and a secondary forward air release pipeline 5 are arranged. An auxiliary line pipeline 6 is arranged between the first-stage pressure swing adsorption unit 1 and the fine d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com