Dehydrogenation method of carbon dioxide feed gas

A carbon dioxide and raw material gas technology, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve the problem of high venting volume in high-pressure systems, and achieve environmental protection control, increase conversion rate, and increase system load. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0023] Example 1: a kind of dehydrogenation method of carbon dioxide feed gas, the steps are as follows:

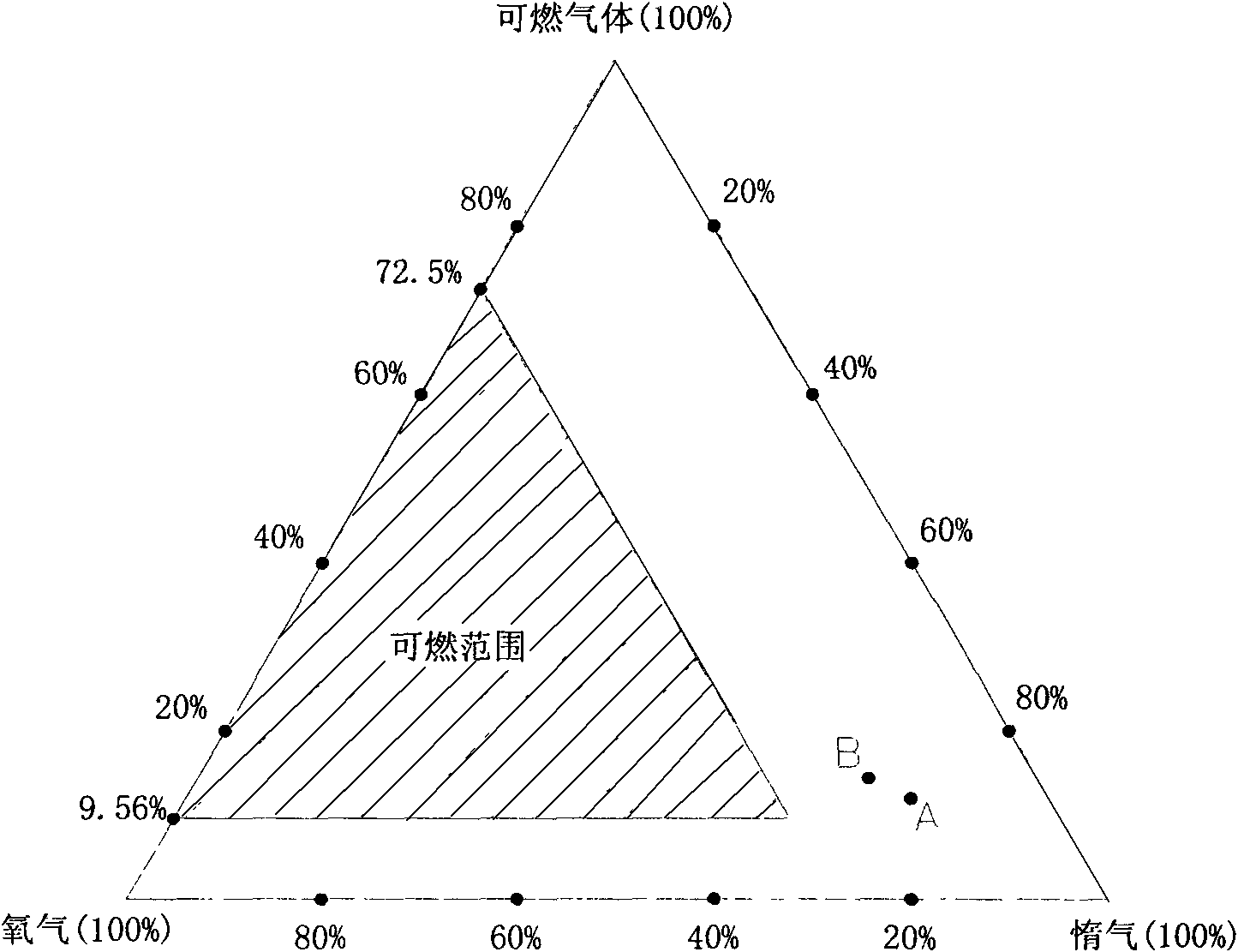

[0024] 1) The 1.0Mpa oxygen from air separation enters the oxygen-enriched air mixer after fast cutting, adjustment and metering. In the oxygen-enriched air mixer, the air with a pressure of 0.35Mpa and a temperature of 40°C is sent out from the air compressor. Mixing, the oxygen content in the mixed air is controlled at 21% to 34%.

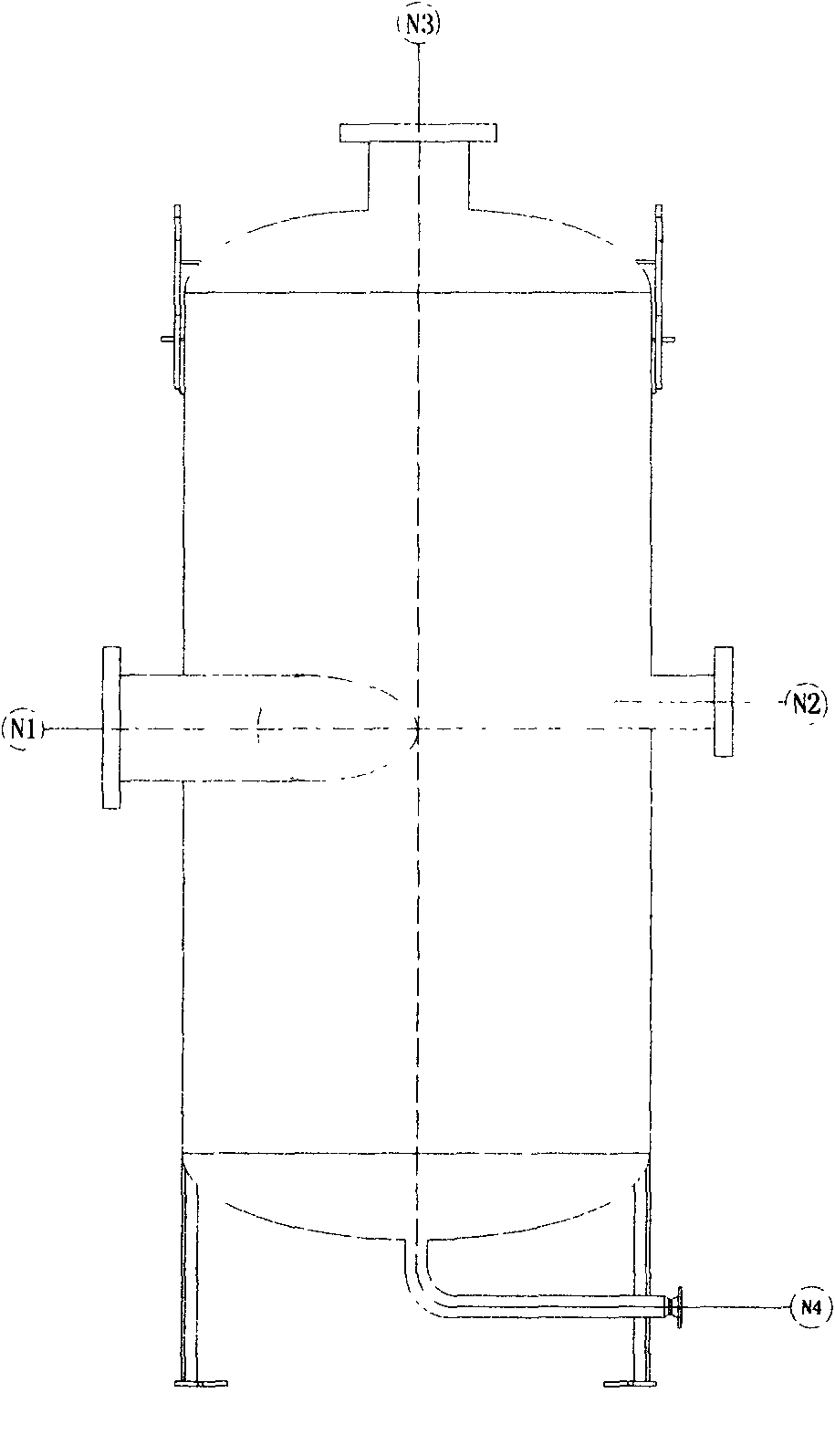

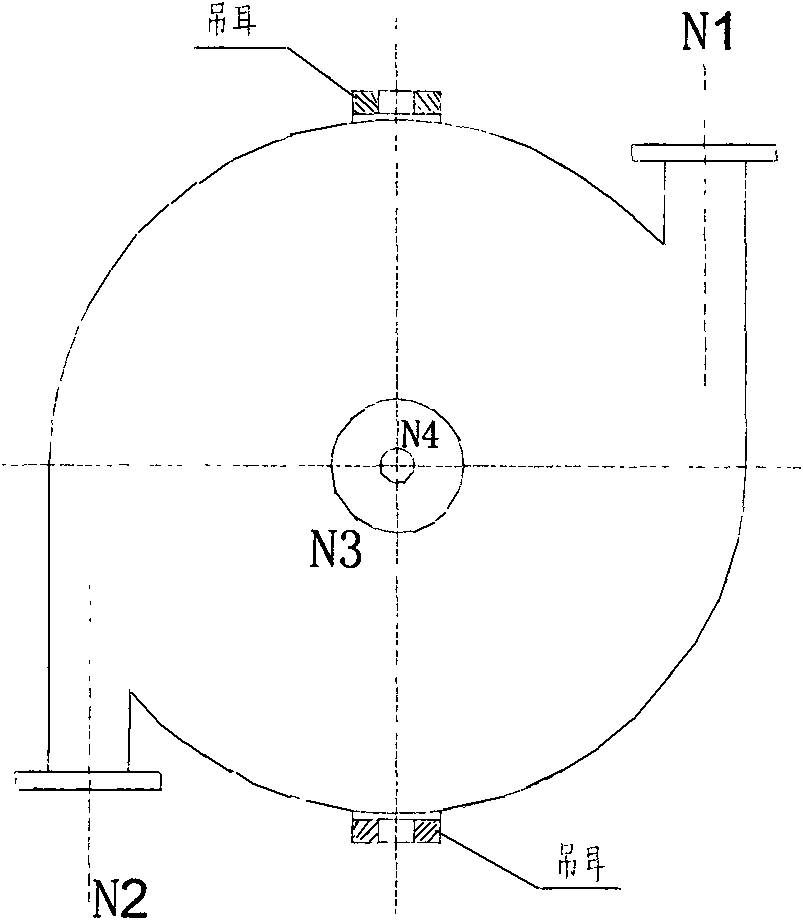

[0025] 2) The mixed air is fed into the inlet of the second stage of the compressor through the solenoid valve, and mixed with carbon dioxide gas. After mixing, the oxygen content in the raw carbon dioxide gas reaches 1.25-1.4%, and after dehydrogenation, the oxygen content reaches 0.65-0.8%. After compression The three-stage compression of the machine enters the desulfurization tank from the outlet of the three-stage oil-water separator, where CO is removed 2 The sulfide in the gas, the total sulfur is normally controlled below 0.2ppm, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com