Energy-saving start system of IGCC power station

A start-up system and energy-saving technology, applied in machine/engine, steam engine installation, combined combustion mitigation, etc., can solve the problems of high fuel cost, high start-up cost, increased power purchase cost, etc., achieve significant energy-saving effect and shorten start-up time , the effect of saving start-up costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

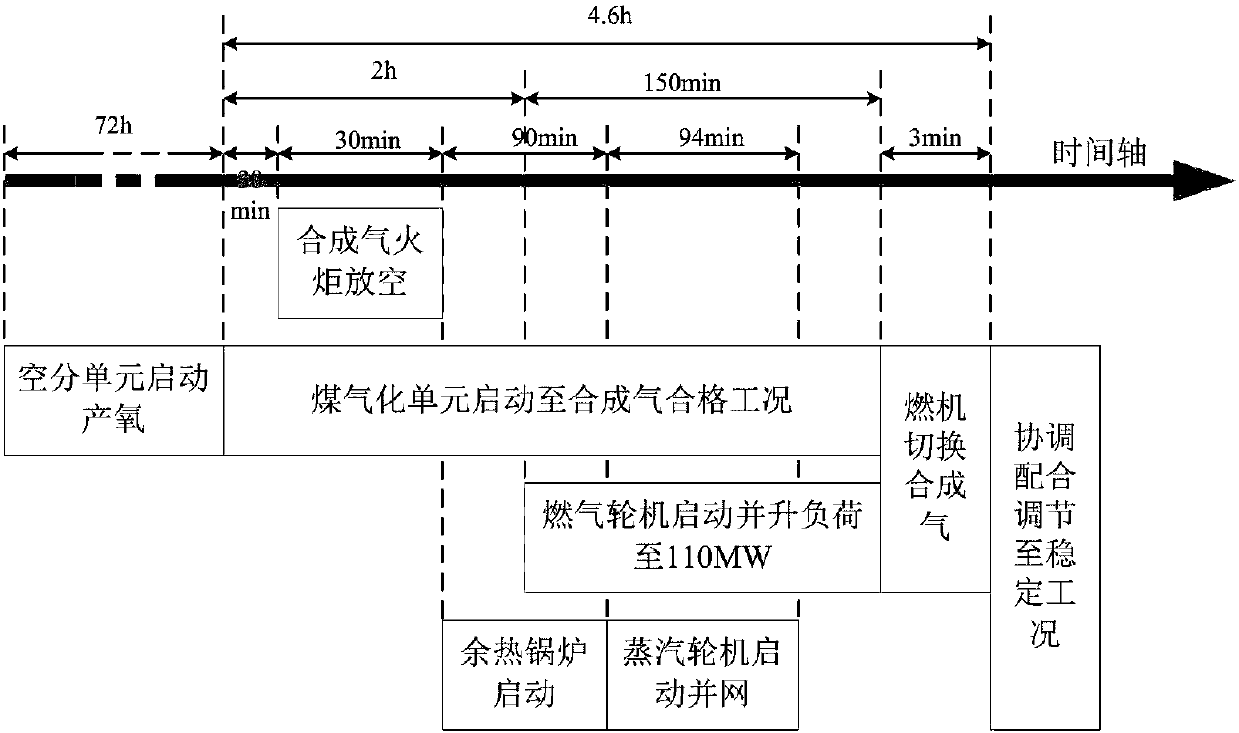

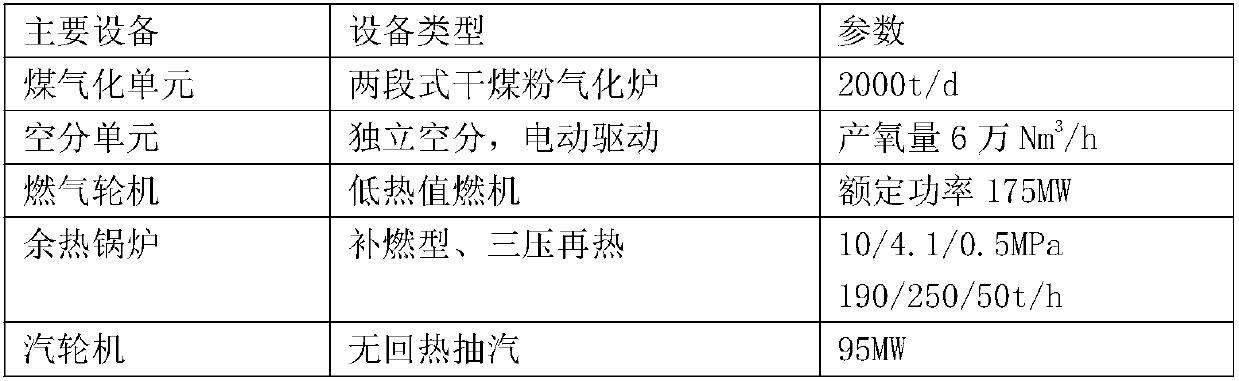

[0019] Below in conjunction with the accompanying drawings, the present invention will be described in detail by taking an IGCC power station with a total generating capacity of 260MW as an example. The main configuration and equipment parameters of the IGCC power station are shown in Table 1.

[0020] Table 1 Main equipment configuration of IGCC power station

[0021]

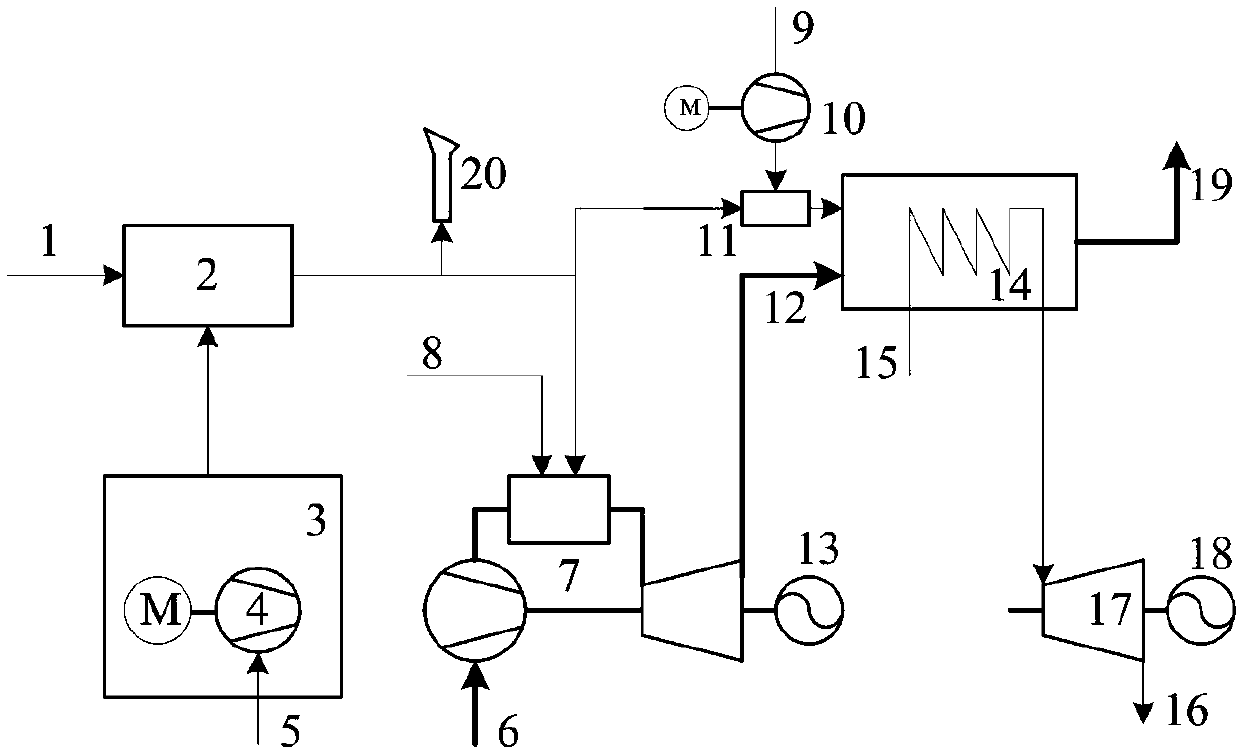

[0022] refer to figure 1 , an energy-saving start-up system for an IGCC power station, comprising a coal gasification unit 2, a pulverized coal inlet of the coal gasification unit 2 is connected to the pulverized coal 1, an oxygen inlet of the coal gasification unit 2 is connected to an oxygen outlet of the air separation unit 3, and the air separation The air compressor 4 inlet of unit 3 sucks the first air 5, and the syngas outlet of the coal gasification unit 2 is divided into three routes, the first route is connected to the flare tower 20, the second route is connected to the afterburner 11, and the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com