Flat heat radiating pipe and manufacturing method thereof

A manufacturing method and heat dissipation pipe technology, applied in the field of heat dissipation, can solve the problems that the working medium delivery capacity of the heat dissipation pipe cannot be fully supplemented, the capillary structure is prone to deformation, disintegration, and the working medium delivery capacity is reduced, so as to prevent the maximum transmission capacity Great reduction of heat, prevention of increase in thermal resistance, and effect of increasing heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

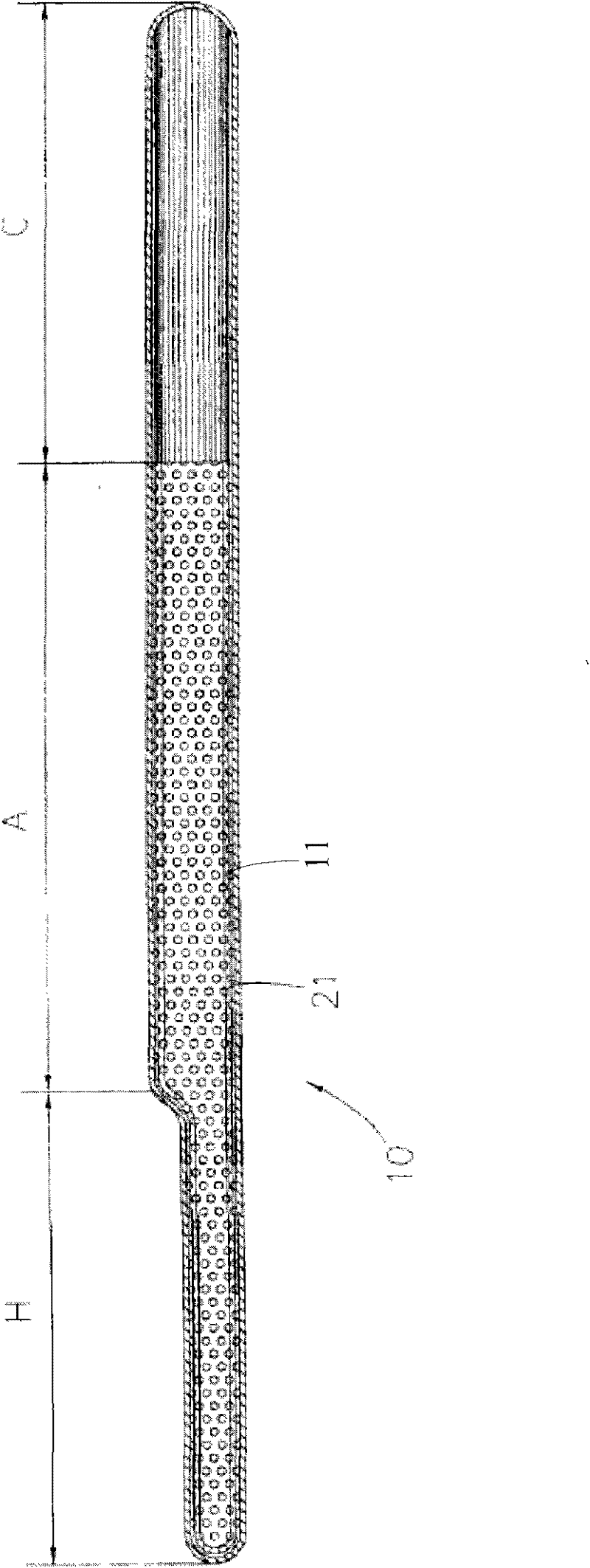

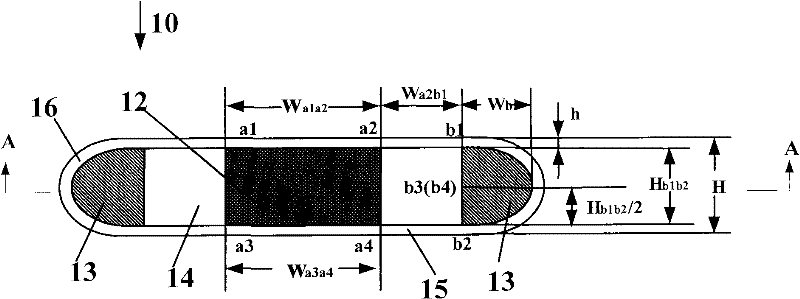

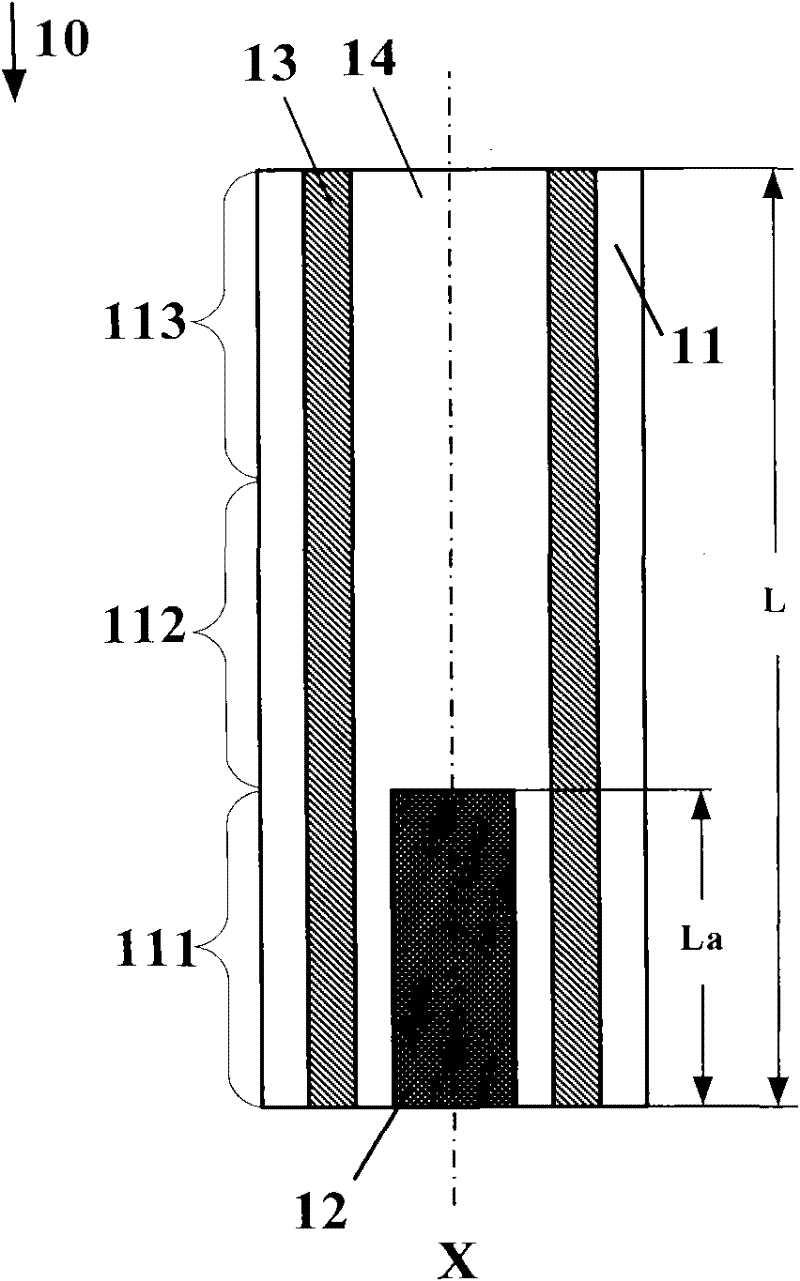

[0042] The embodiment of the present invention provides a flat heat dissipation pipe, which contains a composite capillary structure, that is, includes a main capillary structure and an auxiliary capillary structure, which improves the capillary force of the heat dissipation pipe and increases the delivery capacity of the working medium, thereby increasing the heat of the heat dissipation pipe Transmission efficiency; especially in the evaporation section of the flat heat pipe with high flatness requirements, there will be no obvious depressions, which ensures that the gas passage of the ultra-thin heat pipe after flattening has enough space. The specific implementation of the present invention will be combined with the accompanying drawings below method in detail.

[0043] figure 2 It is a schematic cross-sectional view of the flat heat pipe in the evaporation section perpendicular to the axial direction of the embodiment of the present invention, image 3 yes figure 2 Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com