Deep peak-regulating combination type combustion-stabilizing combustor

A burner and stable combustion technology, applied in the field of boiler combustion, can solve the problems of slow adjustment, poor deep peak shaving ability, and long time consumption, and achieve the effects of stable operation, less maintenance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

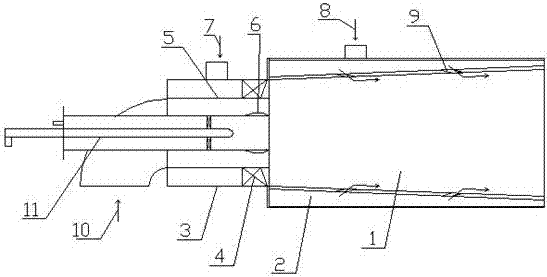

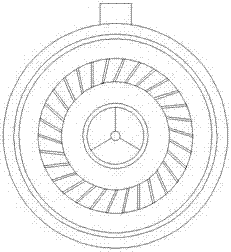

[0021] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a pulverized coal pre-combustion chamber 1 arranged horizontally and communicated with the furnace. The end of the pulverized coal pre-combustion chamber 1 is provided with a primary air chamber 5, and the primary air chamber 5 is connected with a primary air duct and is provided with a primary air coal The powder mixture inlet 10, the secondary air chamber 3 coaxial with the primary air chamber 5 is arranged outside the primary air chamber 5, and the oil combustion cylinder 11 is axially arranged inside the primary air chamber 5; the tertiary air chamber 2 is arranged outside the pulverized coal pre-combustion chamber 1, The tertiary air chamber 2 is connected to the furnace; the tertiary air chamber 2 is provided with a tertiary air inlet 8, and the tertiary air chamber 2 is connected to the pulverized coal pre-combustion chamber 1 through the two-stage purge tuyere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com