Cashmere wool synthetic leather production method

A production method and flake technology, applied in the field of synthetic leather, can solve the problems of dye water color migration, rubbing and fading, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions in the embodiments of the present invention will be clearly and completely described below, obviously, the described embodiments are only some of the embodiments of the present invention, not all of the embodiments.

[0022] A method for producing snowflake synthetic leather, the method comprising the steps of:

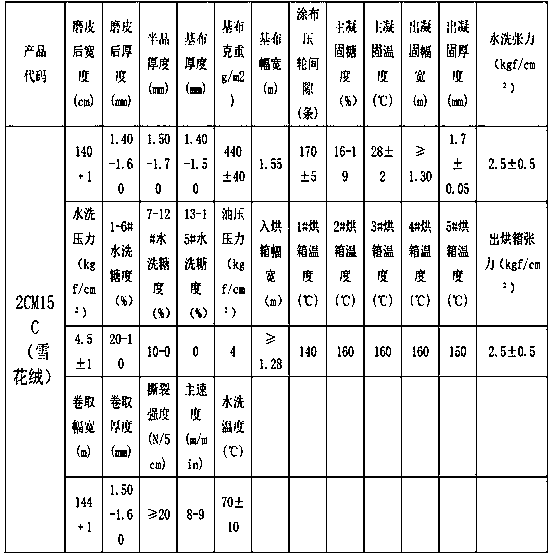

[0023] Step 1. Base fabric selection and processing, thickness selection: 1.40-1.50mm, gram weight 400-480g (weight per square meter), blasting: 15fkg / cm 2 Above, warp stretch: 150N / 3cm or more, weft stretch: 500N / 3cm or more, warp elongation 30%-90%, weft elongation 80%-150%, warp tear strength 50N / 3cm Above, the weft tear strength is more than 30N / 3cm double-sided brushed snowflake base fabric, and the front of the base fabric is finely ground with 240 mesh for one version;

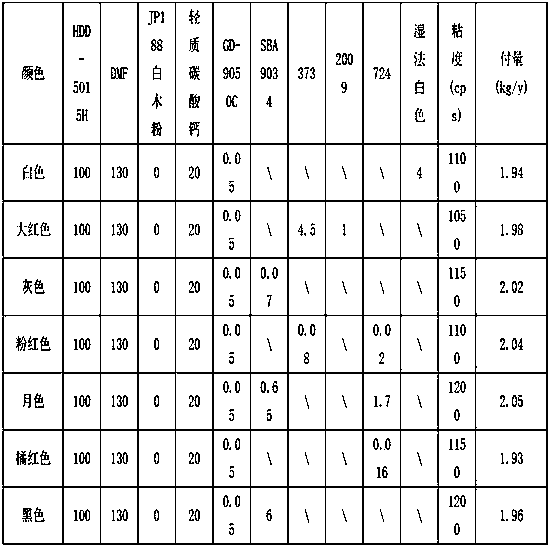

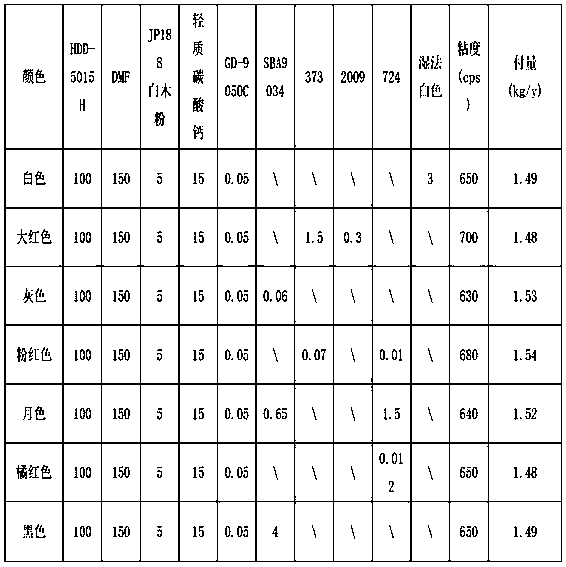

[0024] Step 2, the selection of resin and the batching, select big impregnation 5015 resin for use, its resin index: modulus is 20-30%, solid content is at 29-31...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com