Putty set and preparation method thereof and putty

A kind of putty and kit technology, applied in the direction of filling slurry, etc., can solve the problems of high material cost and labor cost, increase of construction period and construction cost, black primer is stuck by masking tape, etc., to reduce material cost and labor cost Low cost, reduced partial repair cost, excellent overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

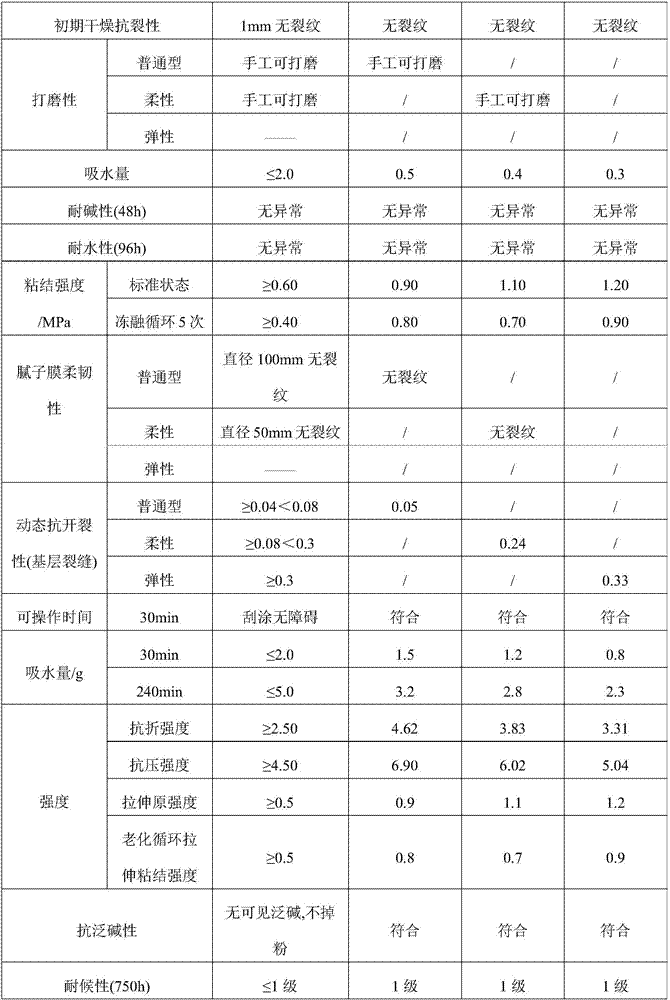

Embodiment 1

[0063] formula:

[0064] The first putty component (liquid material part) in the putty set includes: 200 parts by weight of deionized water, 40 parts by weight of emulsion, 8 parts by weight of carbon black slurry, and 2 parts by weight of preservative;

[0065] The second putty component (powder part) in the putty suit includes: 240 parts by weight of ordinary silicon low-alkali cement, 500 parts by weight of white sand, 4 parts by weight of hydroxypropyl methylcellulose, 2 parts by weight of wood fiber element, 1 part by weight of water repellent, 2 parts by weight of anti-pantherine auxiliary agent, and 1 part by weight of construction modifier.

[0066] Preparation:

[0067] The preparation method of the first putty component: Add the accurately weighed components to the mixing container in sequence, stir until uniform, and pack it into a sealed container to obtain the first putty component of the putty set.

[0068] The preparation method of the second putty component: ...

Embodiment 2

[0072] formula:

[0073] The first putty component (liquid material part) in the putty suit includes: 180 parts by weight of deionized water, 60 parts by weight of emulsion, 9 parts by weight of carbon black slurry, and 1 part by weight of preservative;

[0074] The second putty component (powder part) in the putty suit includes: 220 parts by weight of ordinary silicon low-alkali cement, 520 parts by weight of white sand, 4 parts by weight of hydroxypropyl methylcellulose, 2 parts by weight of wood fiber element, 1 part by weight of water repellent, 2 parts by weight of anti-pantherine auxiliary agent, and 1 part by weight of construction modifier.

[0075] Preparation:

[0076] The preparation method of the first putty component: Add the accurately weighed components to the mixing container in sequence, stir until uniform, and pack it into a sealed container to obtain the first putty component of the putty set.

[0077] The preparation method of the second putty component: ...

Embodiment 3

[0081] formula:

[0082] The first putty component (liquid material part) in the putty suit comprises: the deionized water of 160 parts by weight, the emulsion of 80 parts by weight, the carbon black paste of 8.5 parts by weight, the preservative of 1.5 parts by weight;

[0083] The second putty component (powder part) in the putty suit includes: 180 parts by weight of ordinary silicon low-alkali cement, 560 parts by weight of white sand, 5 parts by weight of hydroxypropyl methylcellulose, 1 part by weight of wood fiber element, 1 part by weight of water repellent, 2 parts by weight of anti-pantherine auxiliary agent, and 1 part by weight of construction modifier.

[0084] Preparation:

[0085] The preparation method of the first putty component: Add the accurately weighed components to the mixing container in sequence, stir until uniform, and pack it into a sealed container to obtain the first putty component of the putty set.

[0086] The preparation method of the second p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com