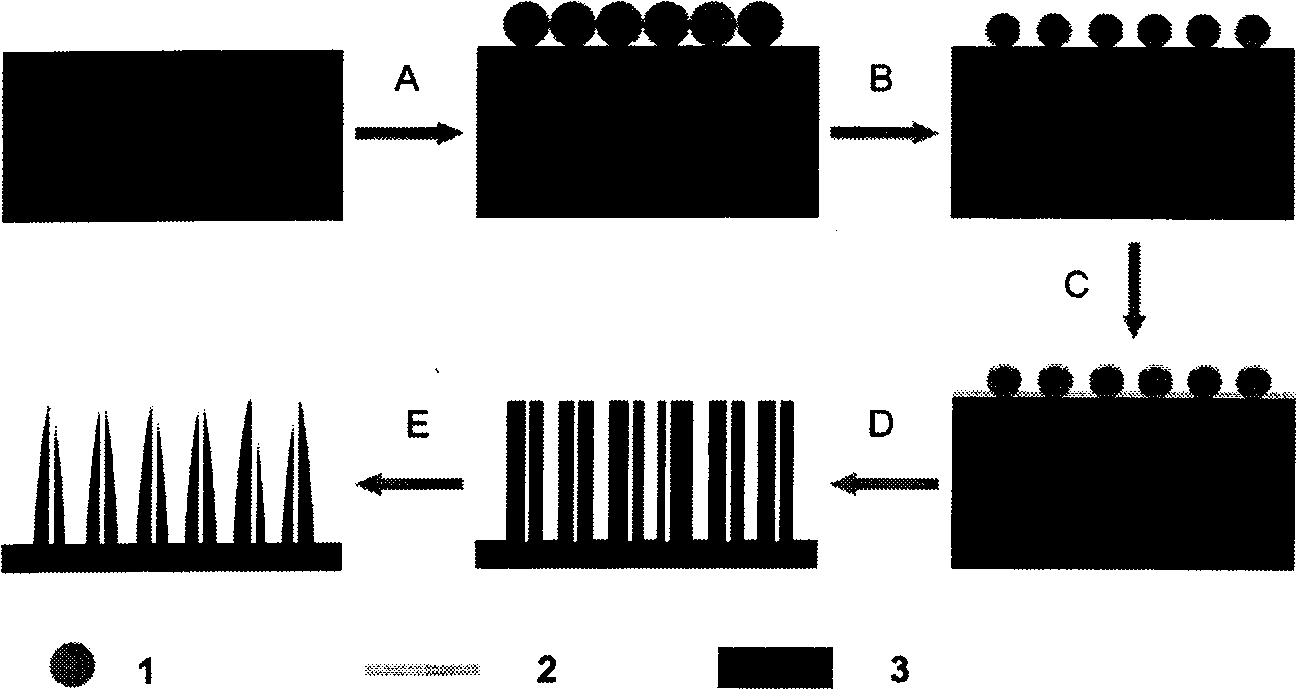

Method for preparing silicon hollow nano-cone array

A nanocone and cone array technology, which is applied in nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of time-consuming, low efficiency, and difficulty in realizing the construction of silicon nanocone arrays, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

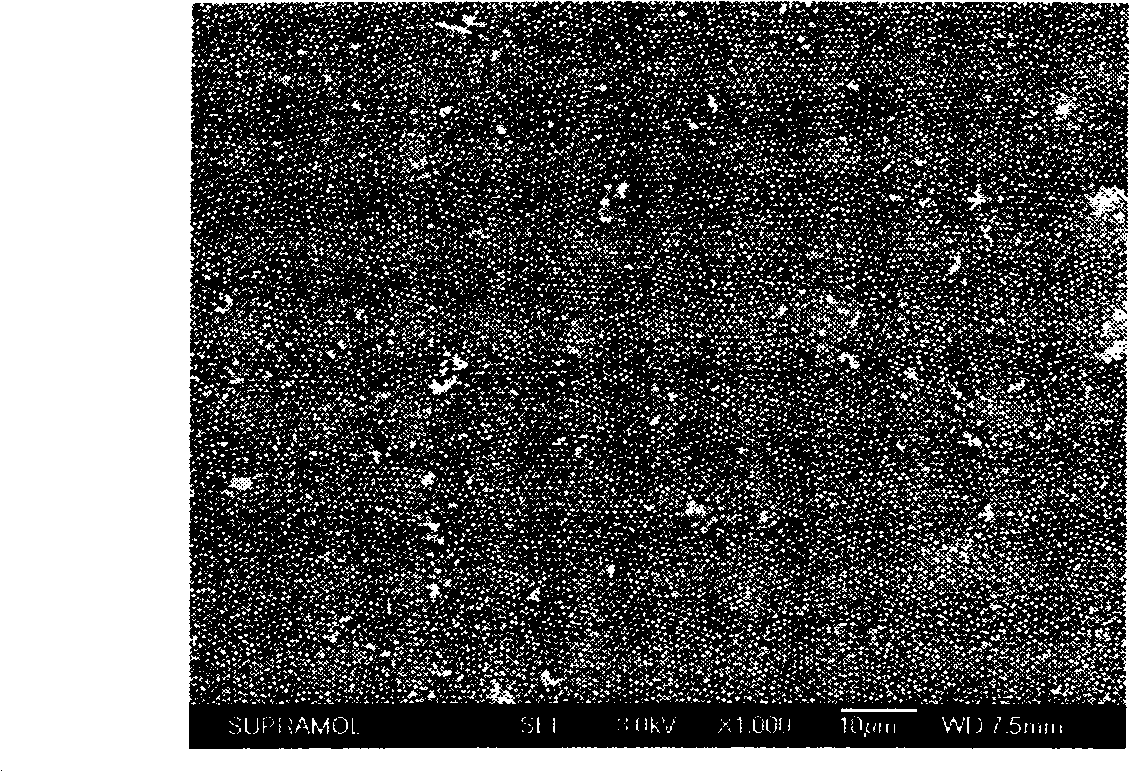

[0040] 1. Preparation method of polystyrene microspheres:

[0041]Under the protection of nitrogen, using 100 ml of absolute ethanol and 40 ml of deionized water as the dispersion medium, add 10.5 ml of styrene, 0.2222 g of potassium persulfate, and 0.2445 g of sodium dodecyl sulfonate to the machine In the reactor of the stirrer and reflux condenser, the mechanical stirring speed is 300 rpm. The dispersion polymerization reaction was carried out in a water bath at 70°C. After 10 hours of reaction, an emulsion of stable milky white monodisperse polystyrene microspheres was obtained. The diameter of the microspheres was 792 nm.

[0042] 2. Preparation of polystyrene monolayer colloidal crystals:

[0043] The prepared polystyrene microspheres were washed by centrifugation, and then dispersed with a mixture solution of absolute ethanol and deionized water with a volume ratio of 1.5:1 to obtain monodisperse polystyrene microspheres with a solid content of 0.5% (mass fraction) Emulsion...

Embodiment 2

[0049] 1. The preparation method of polystyrene microspheres and the preparation method of polystyrene monolayer colloidal crystals are shown in Example 1.

[0050] 2. Preparation of hollow silicon nanopillar array:

[0051] The preparation method of the non-closely packed colloidal crystals is shown in Example 1, and then a 45nm thick silver film is deposited on the substrate with a vacuum evaporation apparatus; then the sample is immersed in a mixed solution of hydrofluoric acid and hydrogen peroxide (hydrofluoric acid concentration is 4.6 mol / L, the concentration of hydrogen peroxide is 0.44mol / L) for 12 minutes, followed by removing the silver film with aqua regia and removing the polystyrene microspheres with chloroform; obtaining a hollow silicon nanopillar array.

[0052] 3. Construction of hollow silicon nanocone array:

[0053] Perform fluorine reactive ion etching on the obtained hollow silicon nanopillar array, the etching power is RF100W, ICP500W, the cavity pressure ...

Embodiment 3

[0055] 1. The preparation method of polystyrene microspheres and the preparation method of polystyrene monolayer colloidal crystals are shown in Example 1.

[0056] 2. Preparation of hollow silicon nanopillar array:

[0057] The preparation method of non-closely packed colloidal crystals is shown in Example 1, and then a 40nm thick silver film is deposited on the substrate with a vacuum evaporation apparatus; then the sample is immersed in a mixed solution of hydrofluoric acid and hydrogen peroxide (hydrofluoric acid concentration is 4.6 mol / L, the concentration of hydrogen peroxide is 0.44mol / L) for 6 minutes, followed by removing the silver film with aqua regia and removing the polystyrene microspheres with chloroform; obtaining a hollow silicon nanopillar array.

[0058] 3. Construction of hollow silicon nanocone array:

[0059] Perform fluorine reactive ion etching on the obtained hollow silicon nanopillar array, the etching power is RF100W, ICP500W, the cavity pressure is 5m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com