TC bearing and its production method

A production method and bearing technology, applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of short service life, large friction resistance, poor erosion resistance, etc., to improve the wetting effect, reduce friction resistance, The effect of improving erosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

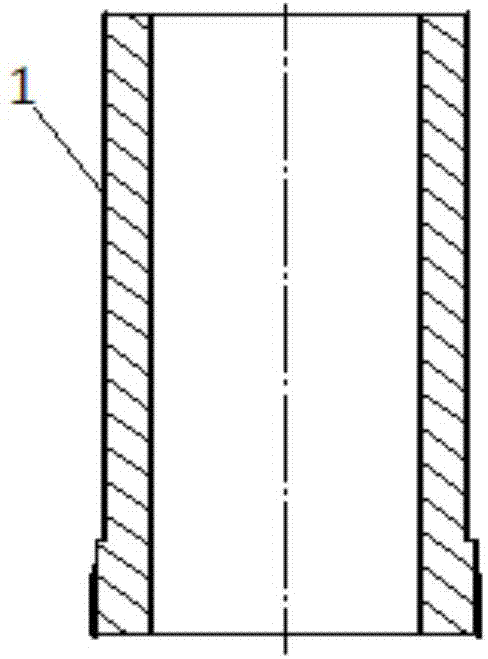

[0049] A TC bearing, comprising a cylindrical upper moving body 1 and a hard alloy wear-resistant layer 6 sintered on the outer surface of the upper moving body 1, the hard alloy wear-resistant layer 6 is made of hard alloy Spheroid 61, cast tungsten carbide powder and copper base alloy are sintered. Such as Figure 11 As shown, a mixture 62 of cast tungsten carbide powder and copper-based alloy is evenly sintered on the surface of cemented carbide pellets 61 and around adjacent cemented carbide pellets 61 .

[0050] Among them, the particle size of cemented carbide pellets is 0.5 mm, and the particle size of cast tungsten carbide powder is 100 mesh.

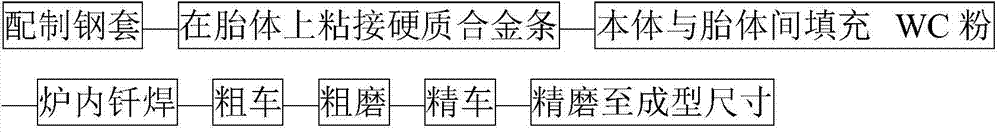

[0051] The production method of the TC bearing, the production method comprises the following steps:

[0052] (1) Preparation of steel sleeves: such as image 3 and Figure 4 As shown, the roughly processed 42CrMo pipe (upper body 1) and 20# steel pipe (upper carcass 2) are processed to the corresponding size according to th...

Embodiment 2

[0062] A TC bearing, comprising a cylindrical upper static sleeve body 7 and a hard alloy wear-resistant layer 6 sintered on the inner surface of the upper static sleeve body 7, the hard alloy wear-resistant layer 6 is composed of hard alloy It is made by sintering high-quality alloy pellets 61, cast tungsten carbide powder and copper-based alloy.

[0063] Among them, the particle size of cemented carbide pellets is 1.0 mm, and the particle size of cast tungsten carbide powder is 200 mesh.

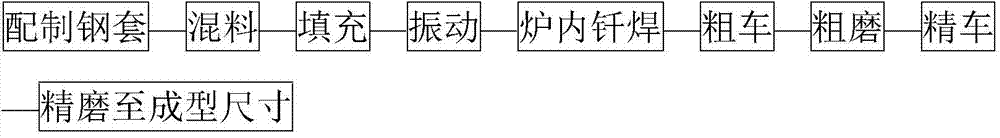

[0064] The production method of the TC bearing, the production method comprises the following steps:

[0065] (1) Preparation of steel sleeves: such as Figure 7 and Figure 8 As shown, the roughly processed 42CrMo pipe (upper static sleeve body 7) and 20# steel pipe (upper static sleeve carcass 8) are processed to the corresponding size according to the drawing requirements, and the outer diameter of the upper static sleeve carcass 8 is smaller than that of the upper static sleeve. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com