Flux cores for high heat-input electro-gas welding gas protection welding wires and gas protection welding wires

A technology of gas-shielded welding wire and gas-electric vertical welding, which is applied in arc welding equipment, welding medium, welding equipment, etc., can solve the problems of narrow application range, achieve the purpose of inhibiting grain growth, expanding the application range, and benefiting comprehensive mechanics performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

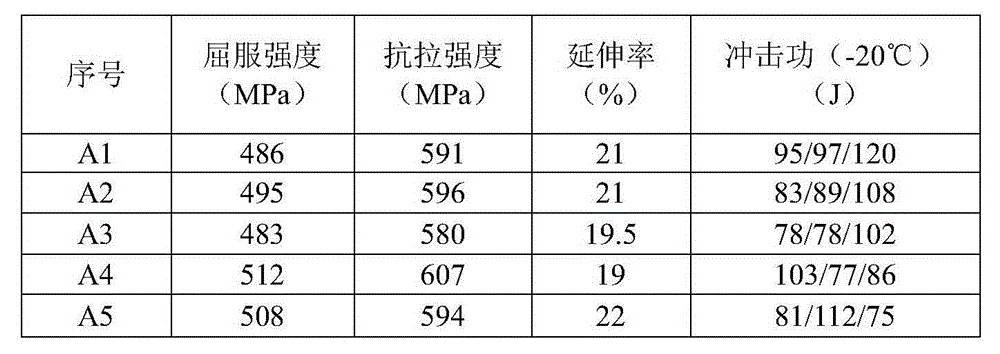

[0089] The flux core of the gas-shielded welding wire, the gas-shielded welding wire and the weld deposit metal of the gas-shielded welding wire for large heat input gas-electric vertical welding according to the present invention will be further explained and illustrated below in conjunction with the description of the accompanying drawings and specific embodiments, however The explanations and illustrations do not constitute undue limitations on the technical solution of the present invention.

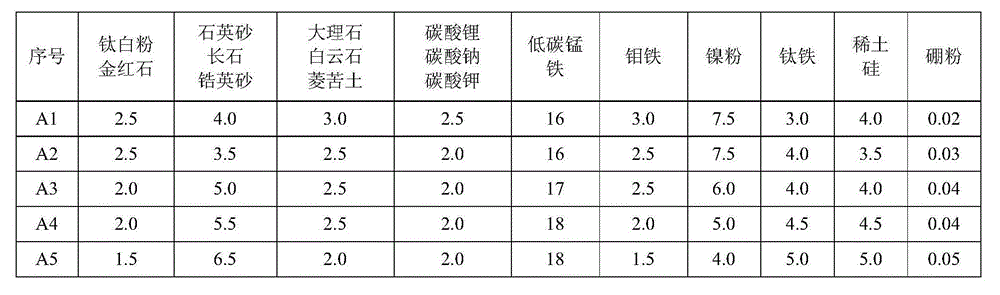

[0090] Table 1 lists the mass percentage distribution ratio of the chemical components of the flux core in Examples A1-A5 of the welding wire of the present technical solution.

[0091] Table 1. (The balance is iron powder, wt.%)

[0092]

[0093] Table 2 lists the mass percentage ratio of chemical elements of the steel sheath of the gas shielded welding wire in Examples A1-A5.

[0094] Table 2. (The balance is Fe and other unavoidable impurities except S and P, wt.%)

[0095] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com