Preparation method of super-hydrophilic super-oleophilic three-dimensional graphene foam material

A graphene foam and super lipophilic technology, applied in ceramic products, other household utensils, household utensils, etc., to achieve high-efficiency adsorption and enrichment, and high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A kind of superhydrophilic and superlipophilic three-dimensional graphene foam material preparation method of the present invention comprises the following steps:

[0028] 1) Preparation of graphene oxide:

[0029] Using the classic HummersandOffema method to prepare graphene oxide from natural graphite powder to obtain a dispersed graphene oxide aqueous solution;

[0030] 2) Preparation of superhydrophilic and superoleophilic three-dimensional graphene foam materials:

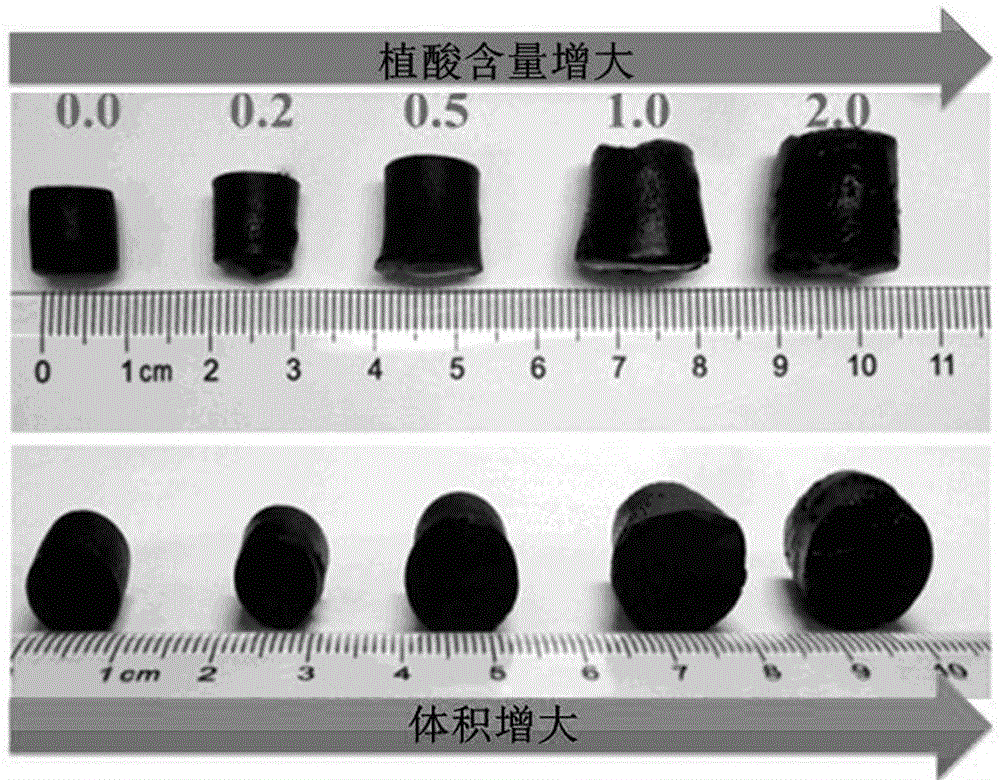

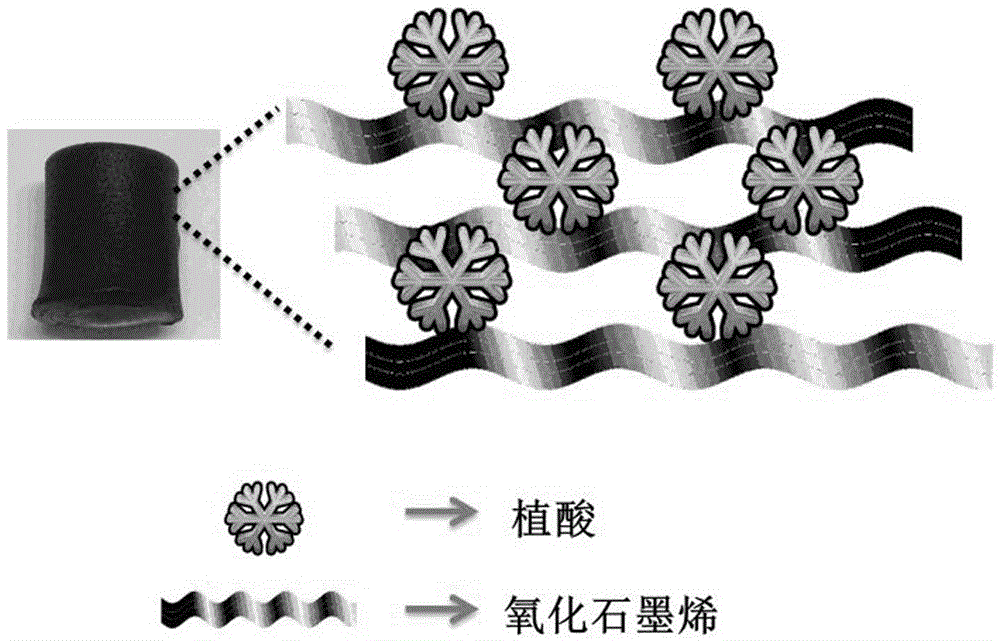

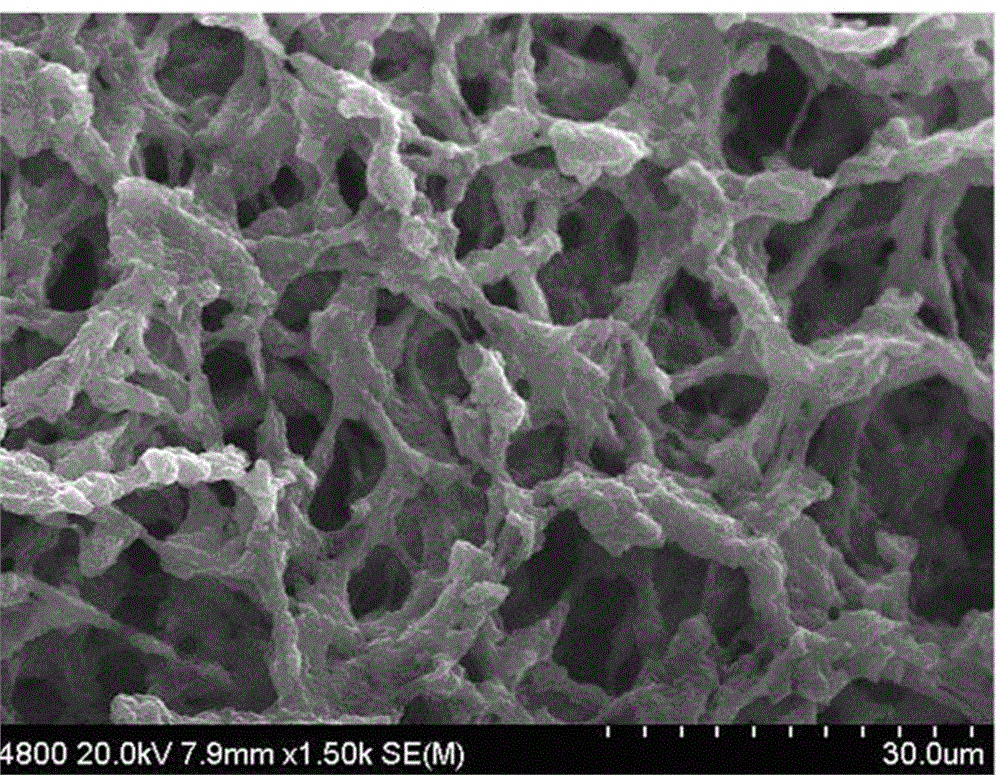

[0031] Put the graphene oxide aqueous solution obtained in step 1) into the reaction kettle, and drop the corresponding dose of phytic acid solution, insert the reaction kettle into a stainless steel jacket, heat it in an oven, keep it at 180oC, and cool it down naturally after 12 hours of reaction. room temperature; the product was freeze-dried for 24 hours to obtain a cylindrical phytic acid-doped super-hydrophilic and super-oleophilic three-dimensional graphene foam material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com