Prefabricated concrete bearing platform with reserved pile nest holes and fabricated multi-pile foundation installation method based on prefabricated concrete bearing platform with reserved pile nest holes

A technology of prefabricated concrete and installation method, which is applied in the direction of infrastructure engineering and construction, and can solve the problems of long period, complicated construction process, and strict requirements on foundation flatness, so as to save construction time, reduce construction cost, and save formwork removal Process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

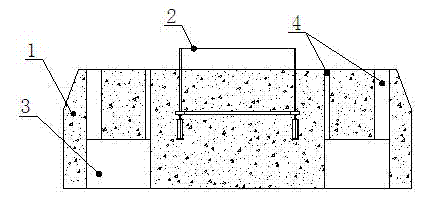

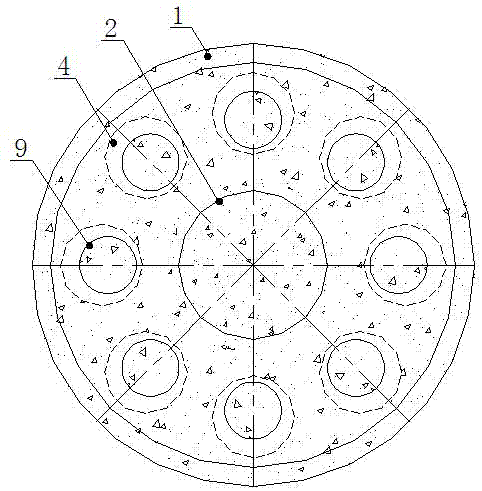

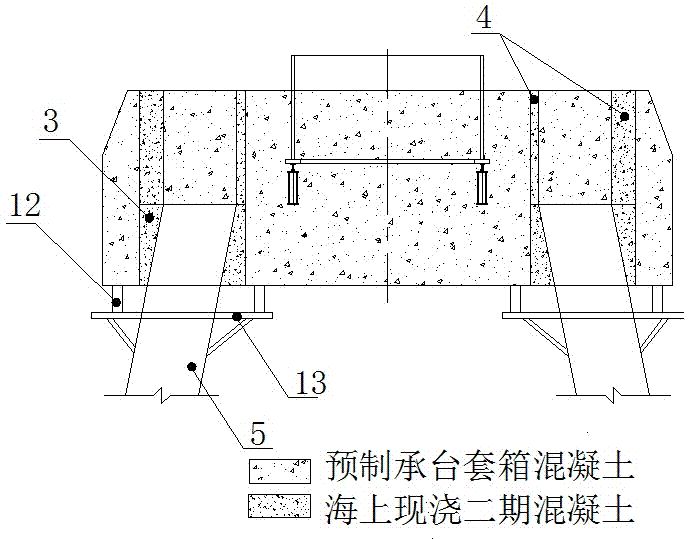

[0035] figure 1 Shown is a prefabricated concrete cap with reserved pile holes, including a concrete body 1, and a foundation ring 2 is poured at the center of the top surface of the concrete body 1 (leveled in advance so that the leveling error of the foundation ring 2 is less than 5mm, Generally, a laser level is used to measure the level. This technique is a common skill in this field and will not be repeated here.), the bottom surface of the concrete body 1 is ring-shaped with a plurality of reserved pile holes 3 corresponding to the positions of the foundation piles 5 (evenly The best setting), the top of each reserved pile hole 3 is provided with a grouting channel 4 penetrating the top surface of the concrete body 1; the circumferential side of the concrete body 1 is evenly provided with a plurality of lifting lugs.

[0036] By replacing the traditional steel box with the prefabricated concrete cap with reserved pile holes, the prefabricated concrete cap not only acts a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com