Fabricated precast concrete box culvert

A prefabricated concrete and prefabricated technology, applied in shaft equipment, earthwork drilling, artificial islands, etc., can solve the problems of large investment in production equipment and hoisting equipment, long construction period of cast-in-place box culverts, and difficulty in producing equipment for box culverts. Achieve the effects of simple production and installation process, wide application range, convenient transportation and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

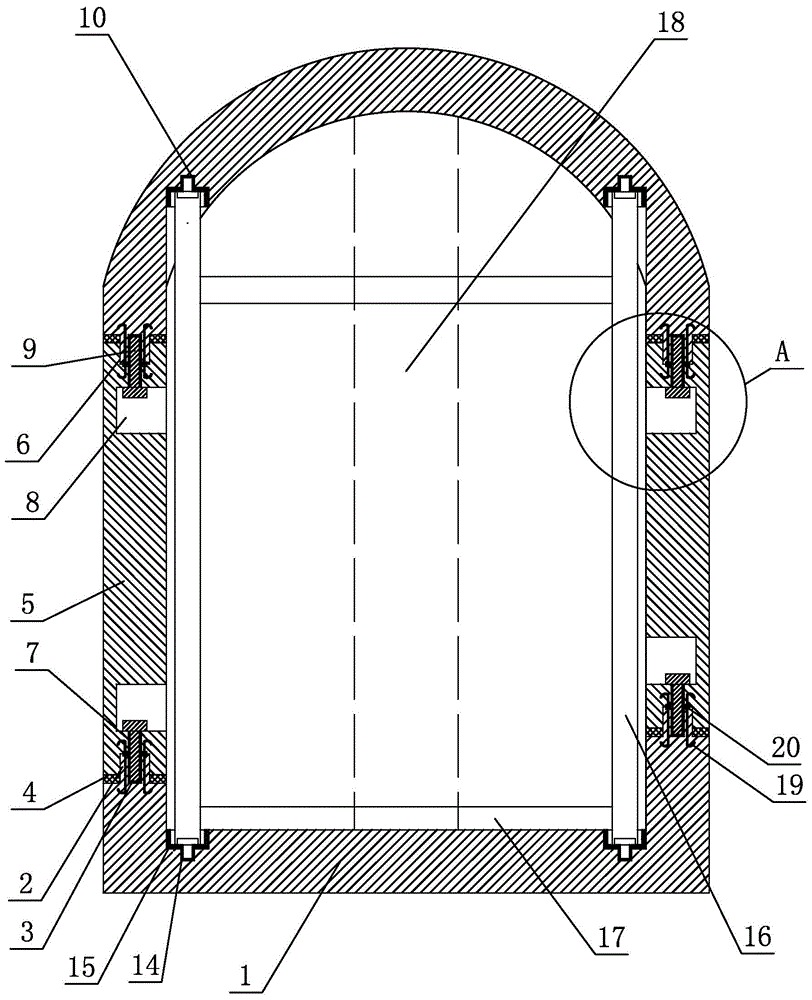

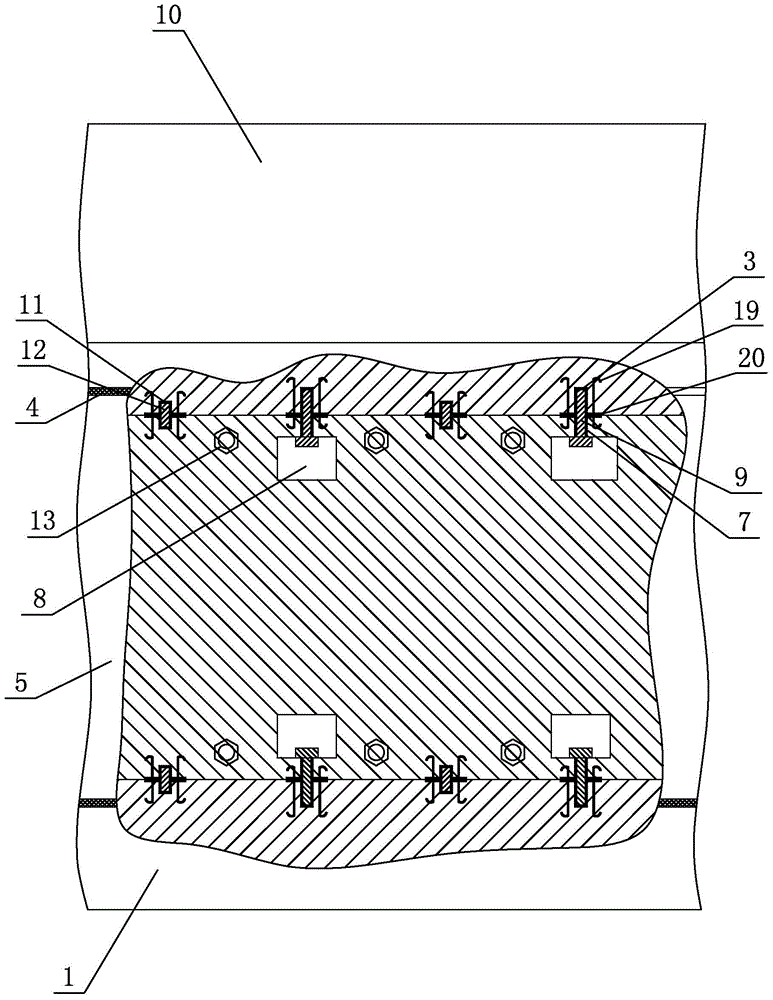

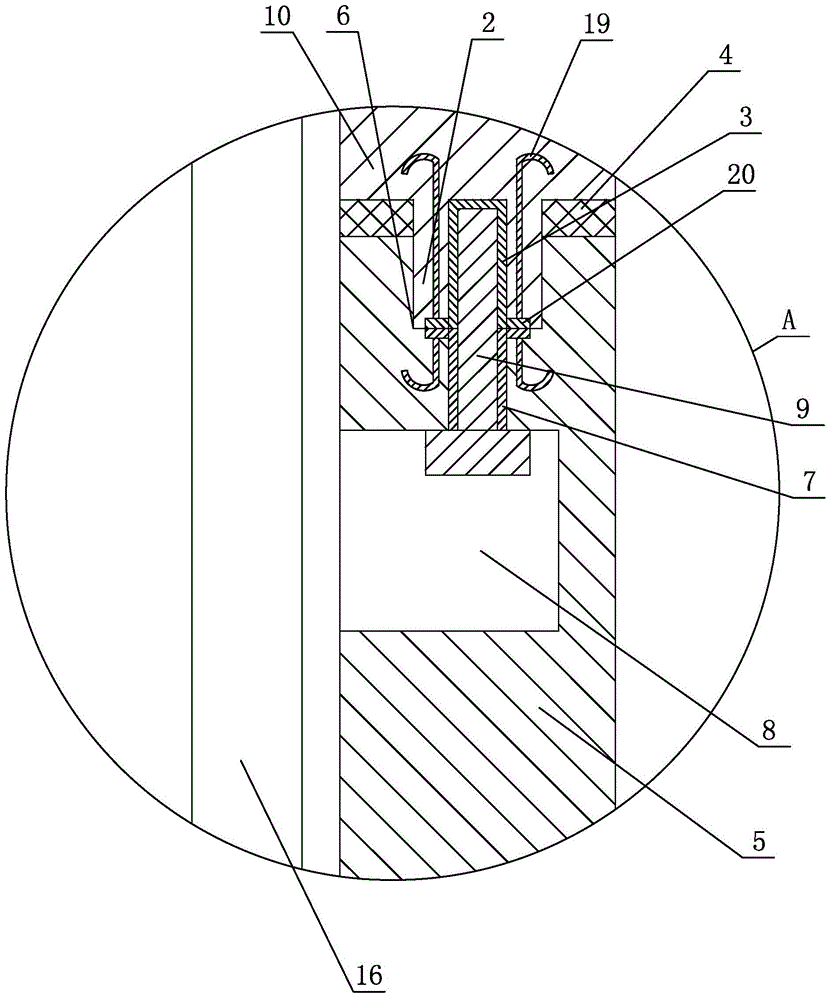

[0020] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

[0021] Such as Figure 1-3 As shown, an assembled prefabricated concrete box culvert includes a trough-shaped base 1 laid horizontally on the ground, and a boss is respectively arranged in the middle of the upper end surface of the vertical plate on both sides of the trough-shaped base 1 along the length direction of the trough-shaped base 1 2. On the top surface of the boss 2 along the length direction of the boss 2, several vertically arranged long hexagonal nuts 3 are embedded at intervals, and a rubber sealing ring 4 is set on the outer bottom of the boss 2. A wallboard 5 is vertically provided above the side vertical board respectively, and a groove 6 is respectively arranged along the length direction of the wallboard 5 in the middle part of the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com