Composite material sheet pile and preparation method thereof

A composite material plate and composite material technology, applied in the field of composite material sheet piles and preparation, can solve the problems of large-scale project use, low strength, poor corrosion resistance, etc., achieve excellent integrity, improve integrity and strength, and improve durability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

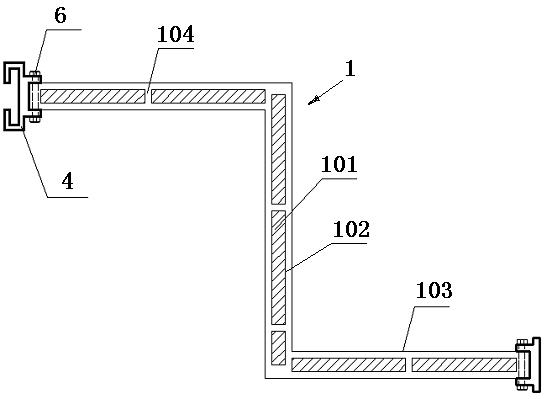

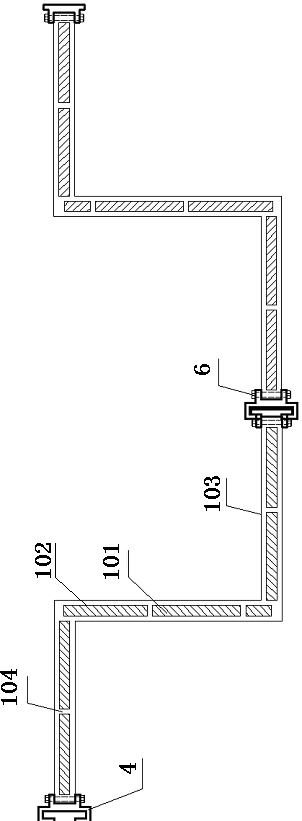

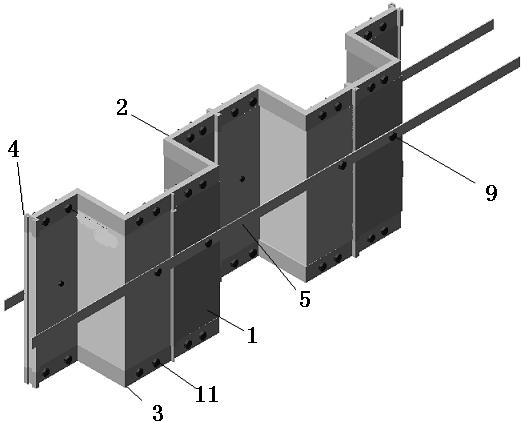

[0061] A composite material sheet pile, comprising a pile body 1, the cross-sectional shape of the pile body 1 is as follows Picture 1-1 As shown, the splicing structure of the pile body 1 and the pile body 1 is as follows Figure 1-2 As shown, the three-dimensional structure of the spliced piles is as follows Figure 1-3 shown. The pile body 1 is a composite material pile body, the upper end of the pile body 1 is wrapped with a stainless steel sleeve 2, the lower end is connected with a stainless steel pile shoe 3, and the two sides of the pile body 1 are respectively connected with adjacent piles. Lock 4 connected to body 1, such as Figure 1-3 As shown; the pile body 1 is composed of a core material 101, an inner wrapping layer 102 wrapping the core material 101 and an outer wrapping layer 103 wrapping each core material 101 wrapped with the inner wrapping layer 102 into a desired shape, adjacent A lattice structure 104 is formed between the core materials 101, such as...

Embodiment 2

[0075] Such as diagram 2-1 , 2-2 , as shown in 2-3.

[0076] The difference between this embodiment and the first embodiment is that the cross-sectional shape of the sheet pile is oblique Z-shaped, and the rest is the same as the first embodiment.

Embodiment 3

[0078] Such as Figure 3-1 , 3-2 , 3-3 shown.

[0079] The difference between this embodiment and the first embodiment is that the cross-sectional shape of the sheet pile is oblique U-shaped, and the rest is the same as the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com