Suspending and guiding device for descending installation of large-scale steel jacket box

A suspension device and guide device technology, applied in the direction of caissons, erection/assembly bridges, bridges, etc., can solve the problems of heavy construction workload, poor construction convenience, slow construction progress, etc., to improve construction quality and facilitate blanking and processing , Improve the effect of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

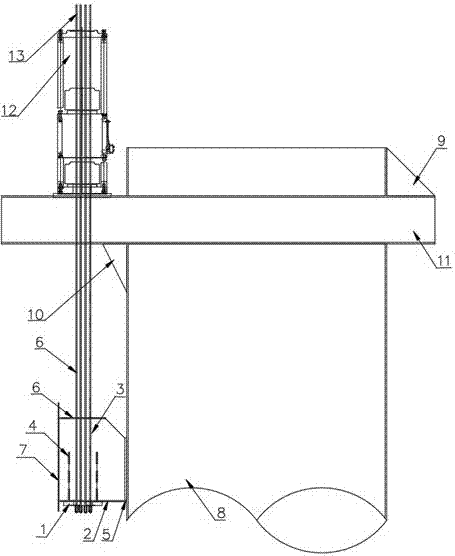

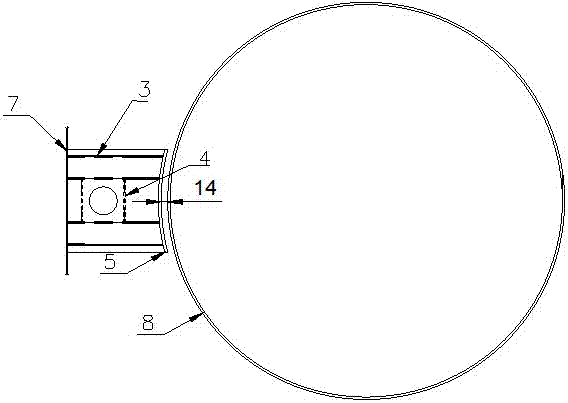

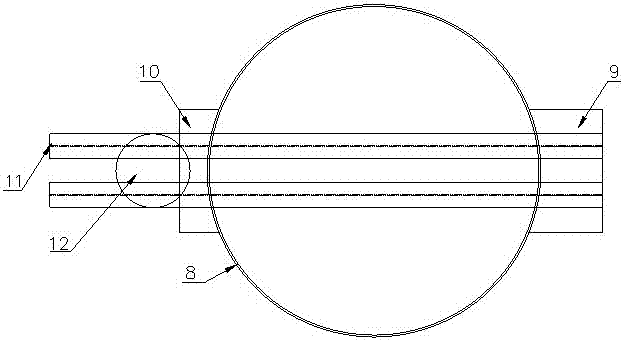

[0016] Such as figure 1 , figure 2 with image 3 The shown suspension device and guide device for the lowering installation of large steel casings has a suspension device and a guide device, and the suspension device has a continuous jack 12 connected with a suspension steel Stranded wire 11, a load-bearing beam 11 is provided under the continuous jack 12, and the guide device includes a pile foundation steel casing 8 arranged under the load-bearing beam 11, and the left side of the pile foundation steel casing 8 is provided with a concentric wall. Arc-shaped plate 5, a concentric space 14 is formed between the pile foundation just casing 8 and the concentric arm-attached arc-shaped plate 5, and the left side of the concentric wall-attached arc-shaped plate 5 is connected with a bottom plate 2 and a top plate 6, and the bottom plate 5 and the left s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com