a cooling tower

A quenching tower and cooling water technology, applied in water shower coolers, direct contact heat exchangers, heat exchanger types, etc., can solve the problems of low incineration treatment efficiency and complicated process, and achieve environmental pollution, energy saving and environmental protection , simple structure, and the effect of improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

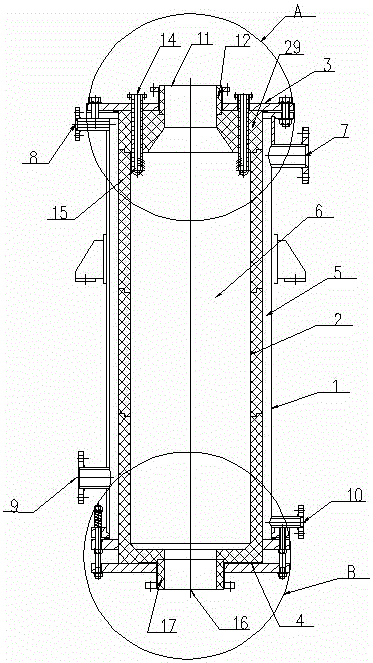

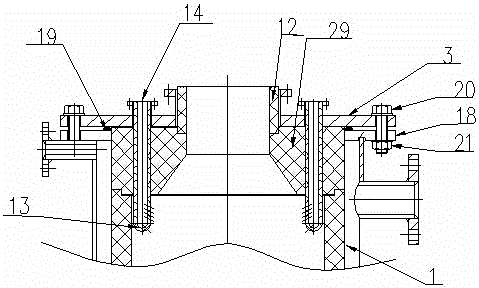

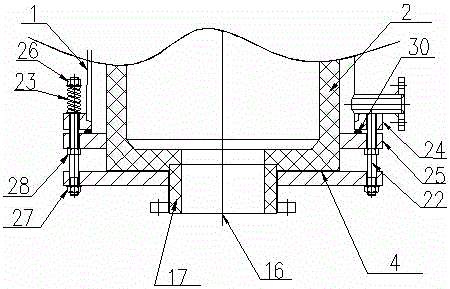

[0033] Such as figure 1 and Figure 4 As shown, a quench tower of the present invention comprises an outer steel jacket 1 and an inner graphite jacket 2, the upper and lower ends of the outer steel jacket are respectively covered with an upper spray cover 3 and a lower cover 4; the inner graphite jacket 2 is Tubular, coaxially installed in the outer steel sleeve 1, and forms a cooling water cavity 5 that can accommodate cooling water circulation with the inner wall of the outer steel sleeve 1, and its inner wall is a spray inner cavity 6 for gas spraying, and its upper end It communicates with the upper spray cover plate 3 through an upper head 29, and its lower end directly communicates with the lower cover plate 4;

[0034] The upper part of the outer steel jacket 1 has a cooling water outlet 7 and an emptying port 8, the cooling water outlet 7 and the emptying port 8 are staggered, and the emptying port 8 is located above the cooling water outlet 7; The lower part has a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com