Novel wet type dust-removing equipment

A technology of wet dust removal and equipment, which is applied in the direction of dispersed particle separation, chemical instruments and methods, and the use of liquid separation agents, etc. It can solve the problems of general dehydration effect, increase the running resistance of fans, reduce the operating efficiency of fans, etc., and achieve the goal of improving the dehydration effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

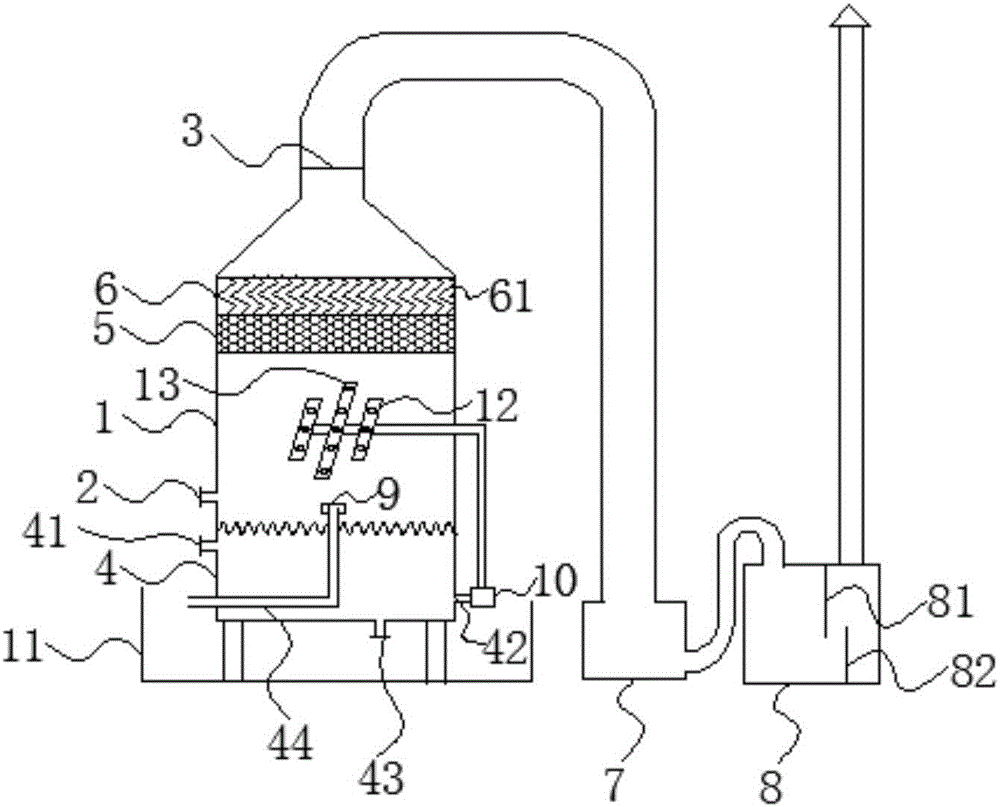

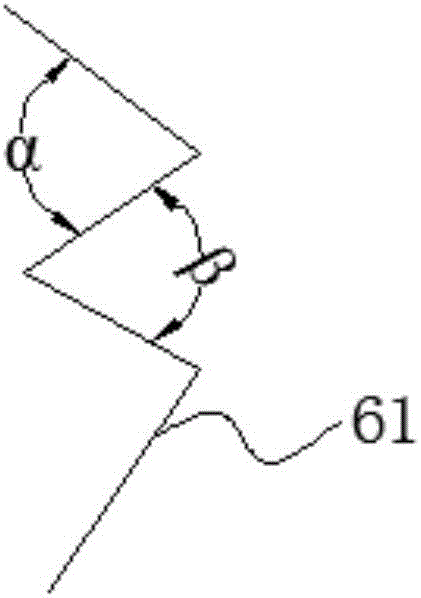

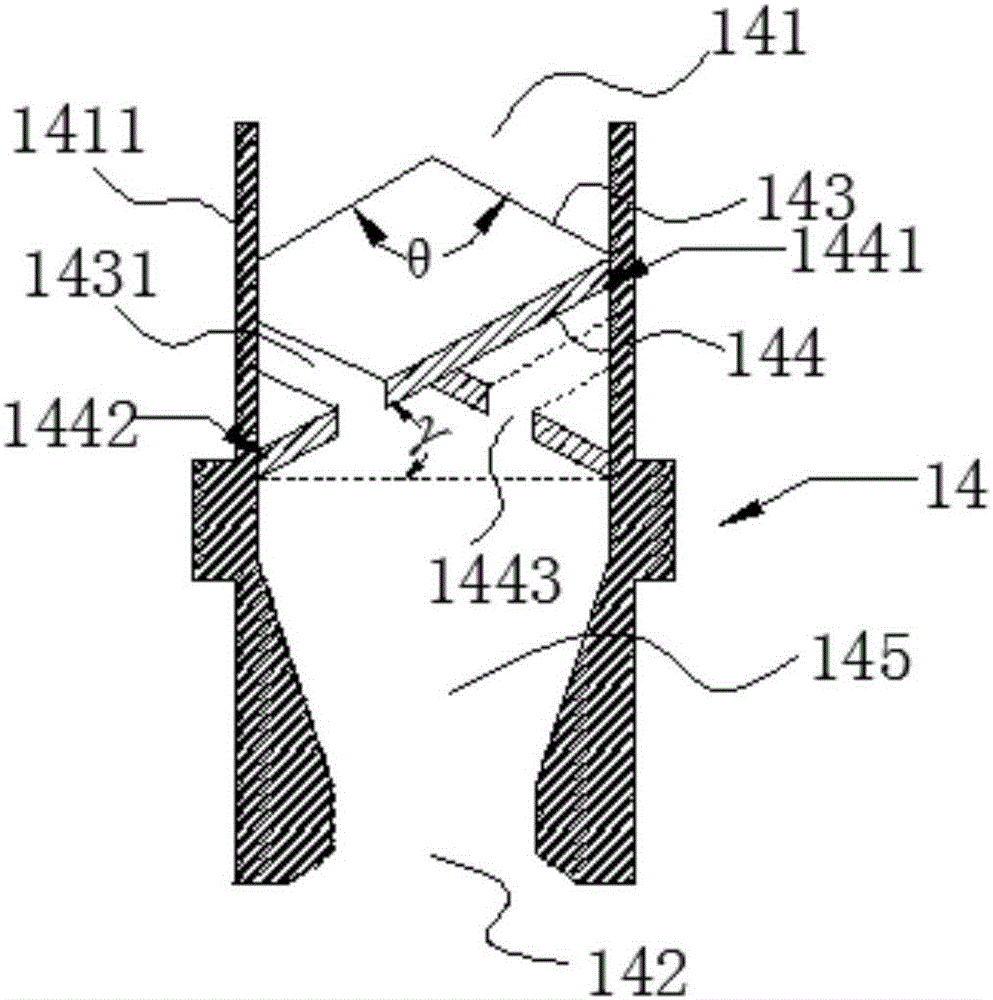

[0043] Embodiment: a kind of novel wet type dedusting equipment, as Figure 1-6 Shown, the present invention comprises the tower body 1 of cylindrical structure, and the side wall of described tower body 1 is provided with air inlet 2 and its upper end is provided with air outlet 3, and described tower body 1 is provided with storage tank in sequence from bottom to top. Water device 4, spray device, dewatering mist packing layer 5 and dehydration layer 6, the air inlet 2 is located between the water storage device 4 and the spray device, the dehydration layer 6 is located at the outlet Below the air port 3;

[0044] Also comprise fan 7 and buffer box 8, the air inlet of described fan 7 communicates with the air outlet of described tower body 1, the air outlet of described fan 7 communicates with the air inlet of described buffer box 8, and the buffer The air outlet of the box 8 is externally connected to the exhaust pipe;

[0045] The water storage device 4 has a first water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Top angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com