Sink dishwasher panel with spraying arms

A dishwashing machine and spray arm technology, applied in the direction of tableware washing machine/rinsing machine, tableware washing machine/rinsing and rinsing machine parts, cleaning equipment, etc., can solve the problem of bacteria unfavorable to the cleanliness of the sink dishwasher and maintain the cleaning process Frequent, affecting customer experience and other problems, to achieve the effect of concealed and reliable structure, reduce spray dead angle, and good spray effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

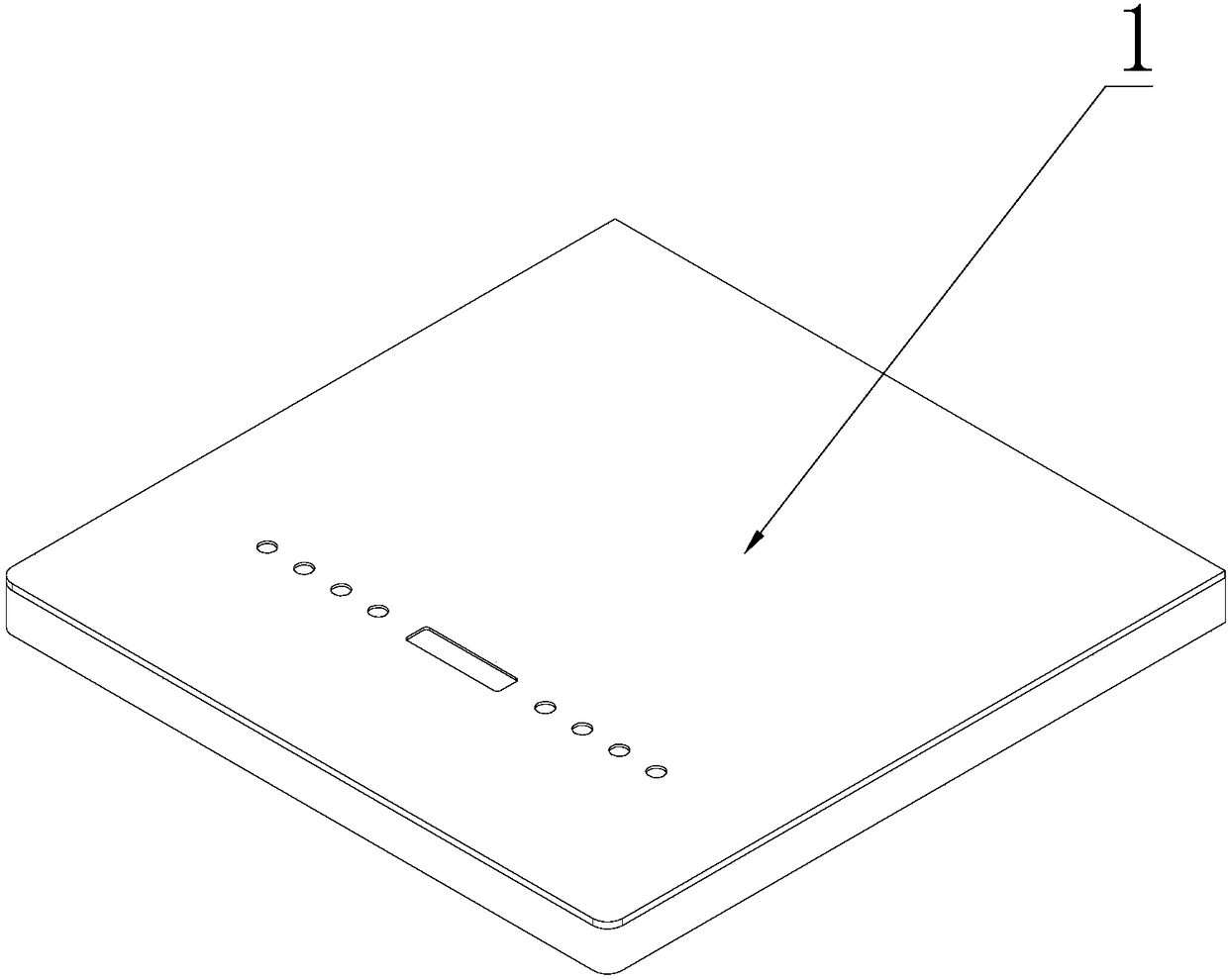

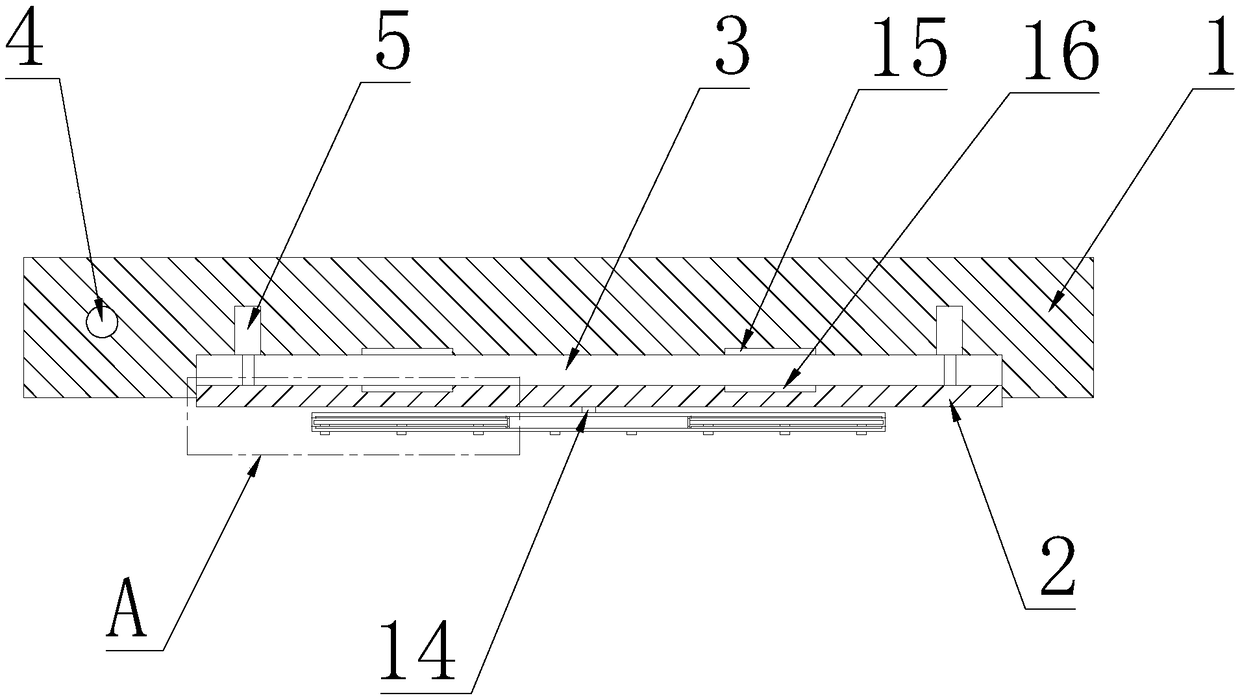

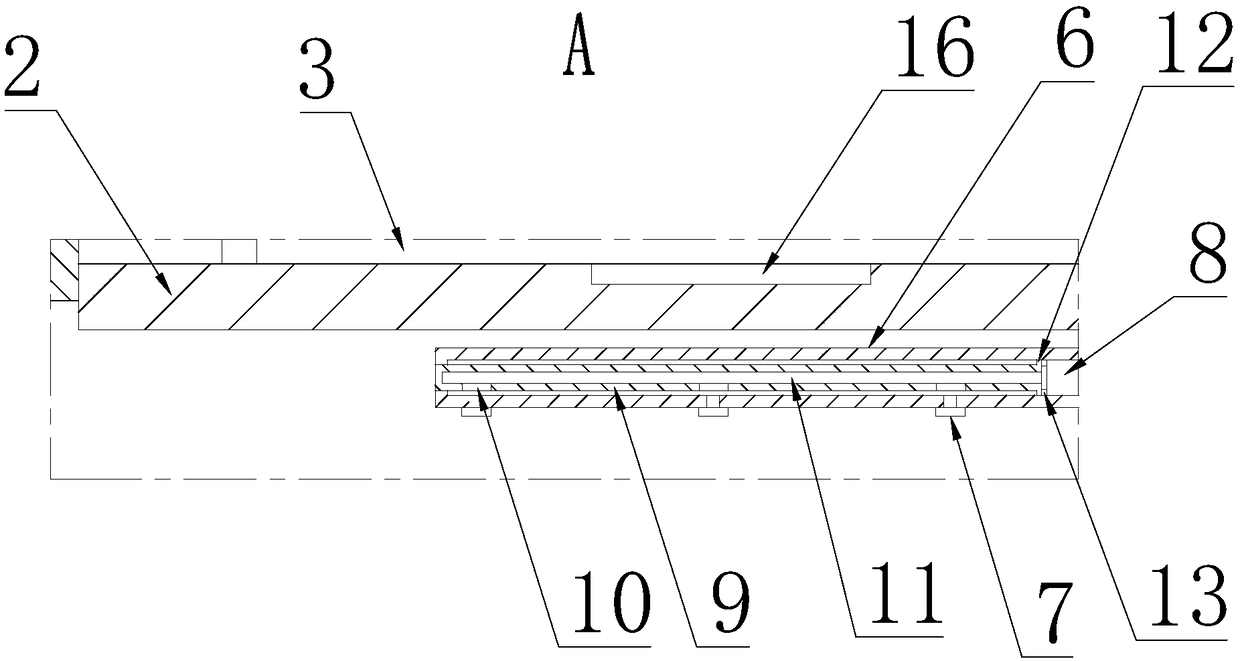

[0020] The present invention provides a sink dishwasher panel with a spray arm, which includes a panel body 1, the lower end surface of the panel body 1 is provided with a mounting groove, and a movable block 2 is placed in the mounting groove, and the movable block 2 is arranged along the vertical direction. Slidingly fit with the installation groove, and the side wall of the movable block 2 is attached to the inner side wall of the installation groove, so that the upper end surface of the movable block 2 and the inner surface of the installation groove are enclosed to form a closed working chamber 3, the The panel body 1 is provided with a water inlet pipe 4 for supplying the water flow of the working chamber 3. The panel body 1 is located above the movable block 2 and is provided with a plurality of hydraulic cylinders 5 arranged at intervals...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com