Activated carbon regeneration device

A regeneration device and activated carbon technology, which is applied in filter regeneration, filtration separation, petroleum industry, etc., can solve the problems of complex activated carbon regeneration device and large investment, and achieve the effect of reducing the dead angle of spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

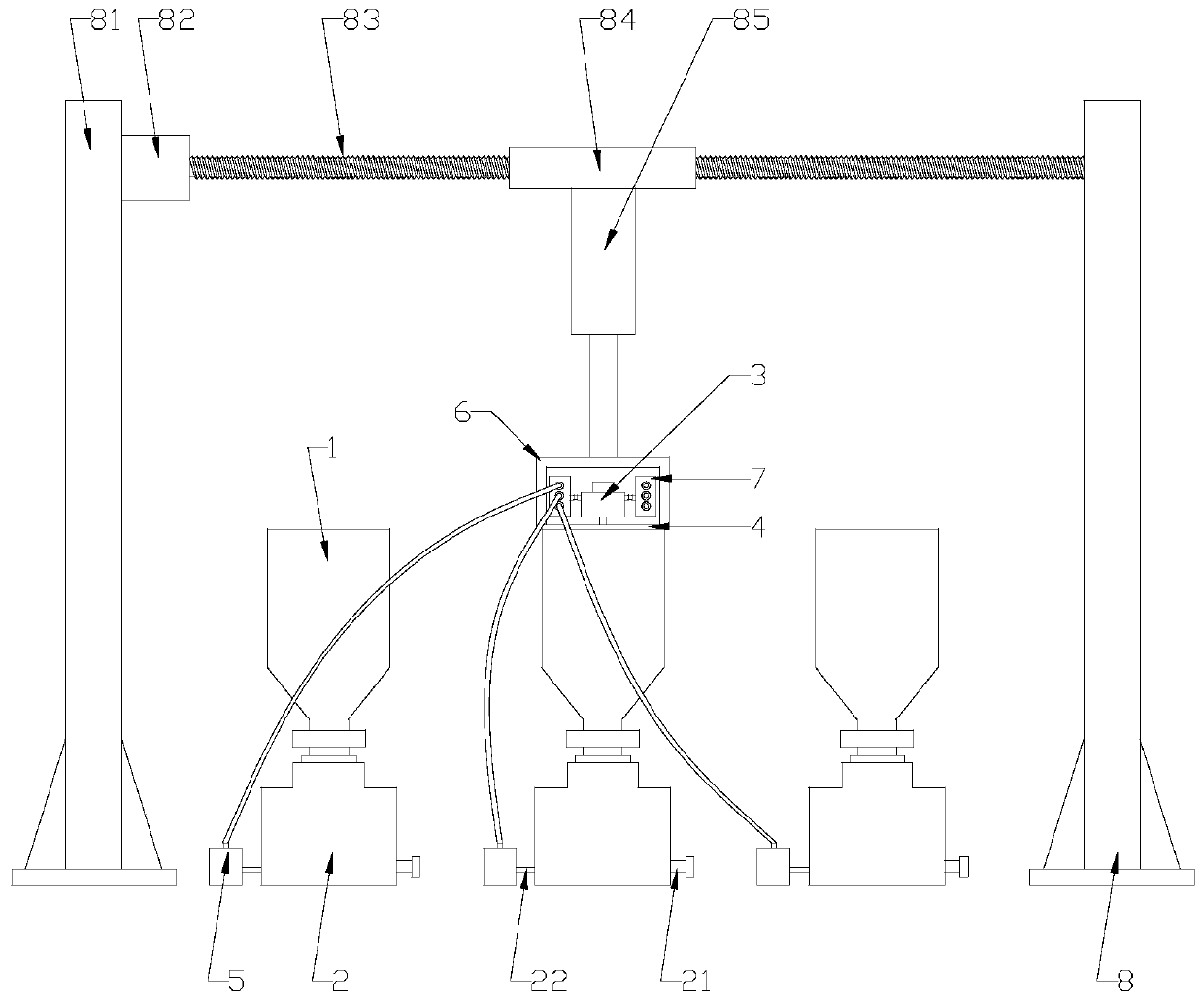

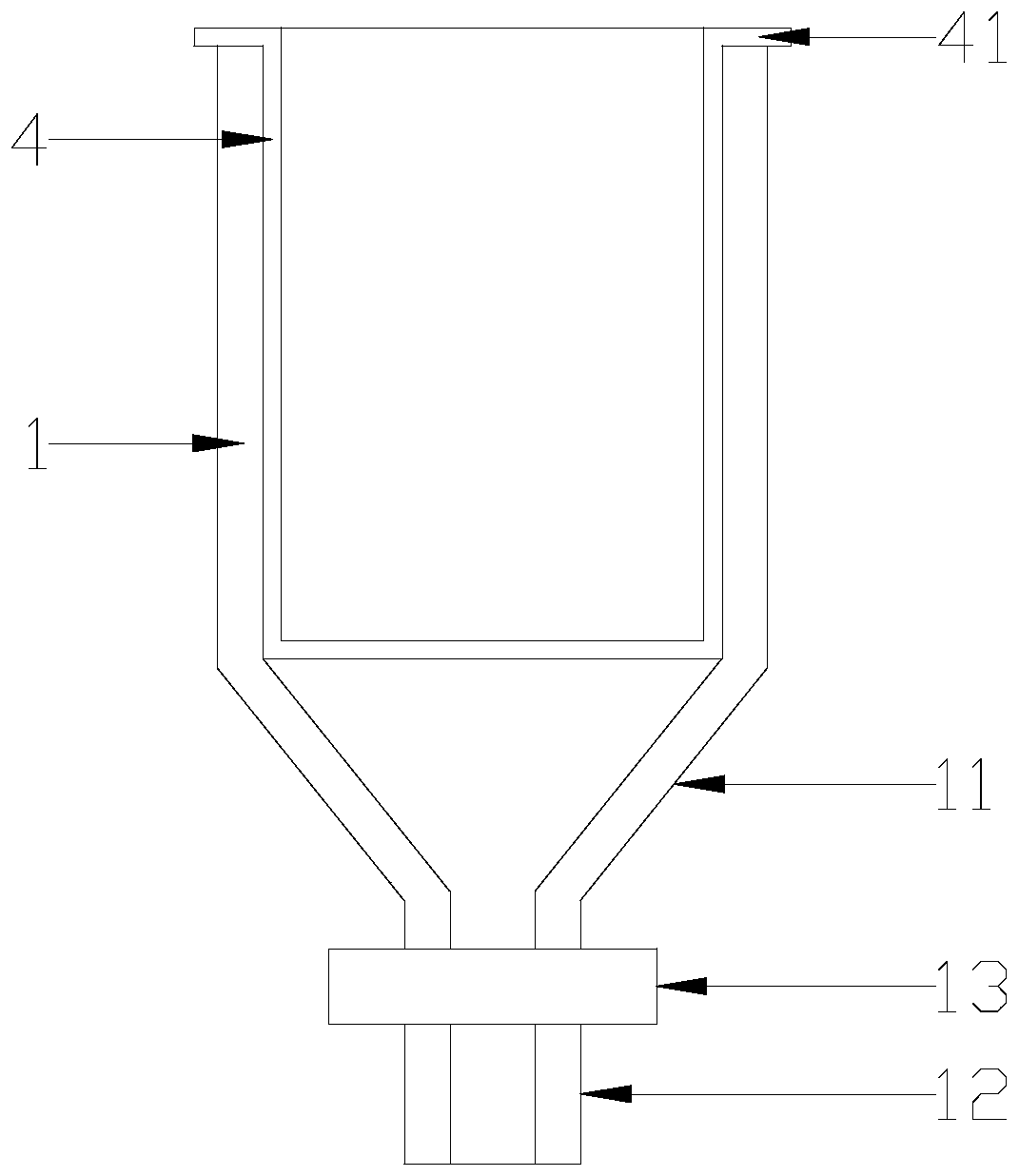

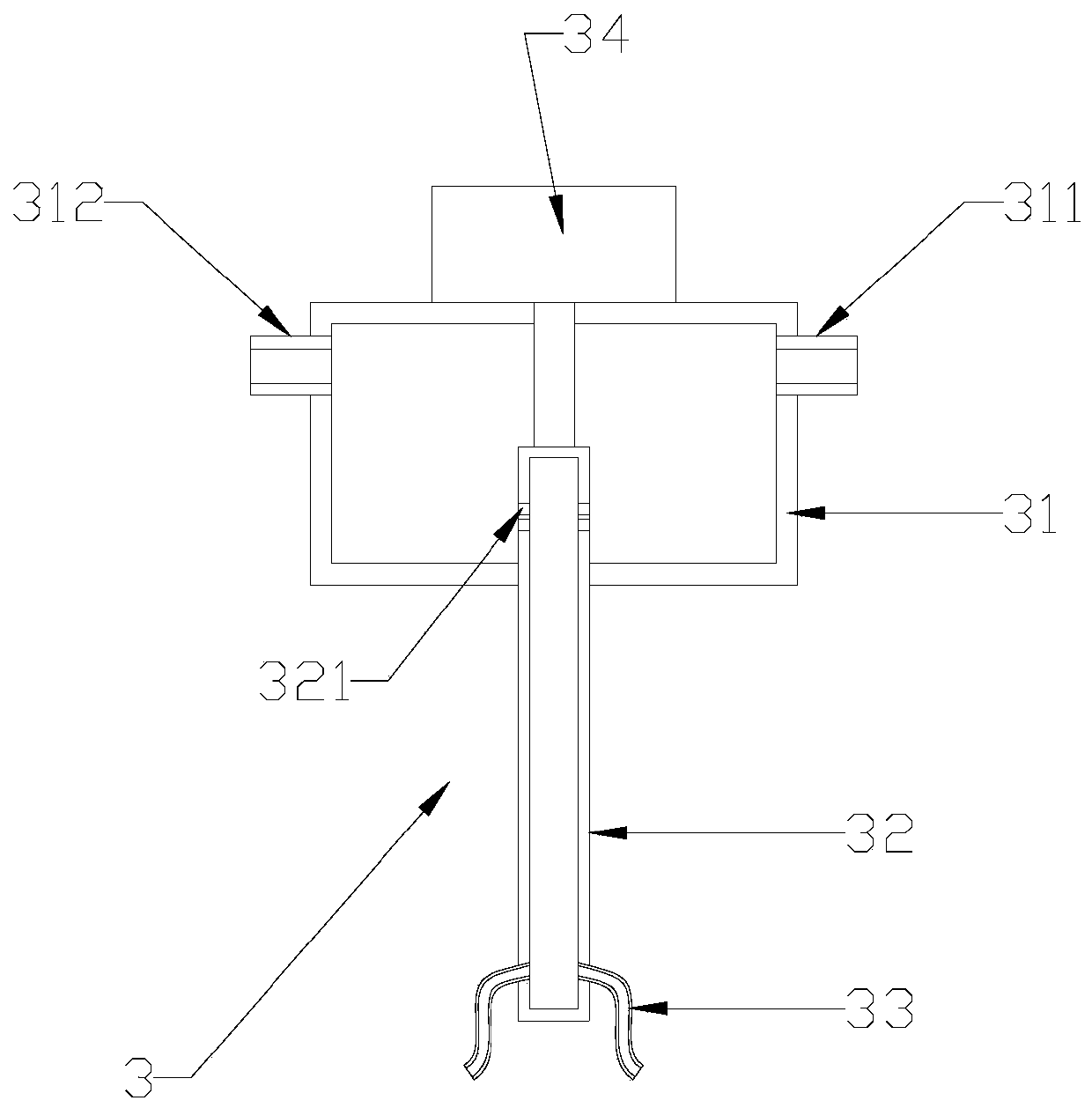

[0018] refer to Figure 1 to Figure 4 , an activated carbon regeneration device of the present invention, comprising a tank body 1, a filtrate tank 2, a sprayer 3, a material frame 4, a pump 5, a support frame 6, a liquid collector 7 and a transmission frame 8, and several tank bodies 1 are arranged in sequence Below the transmission frame 8 and the lower side is provided with a conical section 11 with a liquid outlet 12, and the liquid outlet 12 stretches into different filtrate tanks 2 respectively and is provided with a first solenoid valve 13, the pump 5 are respectively arranged on one side of the filtrate tank 2, the material frame 4 is placed in one of the tanks 1, the sprayer 3 is fixed on the top of the material frame 4 through the support frame 6 and the spray head extends into the material frame In 4, the transmission frame 8 drives the material frame 4 and the sprayer 3 to transfer between different tanks 1 through the support frame 6, and the two sides of the spra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com