Asphalt waste gas purification system

An exhaust gas purification system and asphalt technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of incomplete contact of exhaust gas with water mist, dead spots of spraying, poor particle settlement effect, etc., to reduce spraying Possibility of soaking dead corners, improvement of thoroughness, and effect of increasing coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

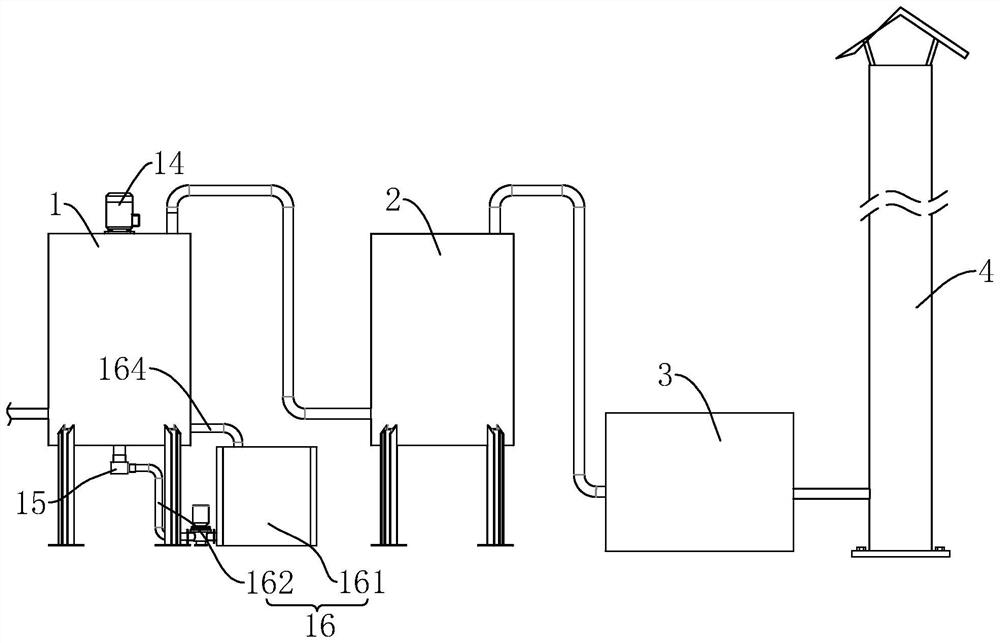

[0038] This embodiment discloses an asphalt waste gas purification system, referring to figure 1 , including a spray tower 1 for removing impurities from asphalt waste gas, a gas-liquid separation device 2 for dehydrating asphalt waste gas, a bitumen waste gas purification unit 3 for removing oily substances in asphalt waste gas, and the purified The exhaust gas is discharged from the high exhaust pipe 4 of the external environment. In this embodiment, the gas-liquid separation device 2 adopts a gravity sedimentation separation type gas-liquid separator, and the asphalt waste gas purification unit 3 adopts Kechuang SCGF series asphalt waste gas purification unit 3 .

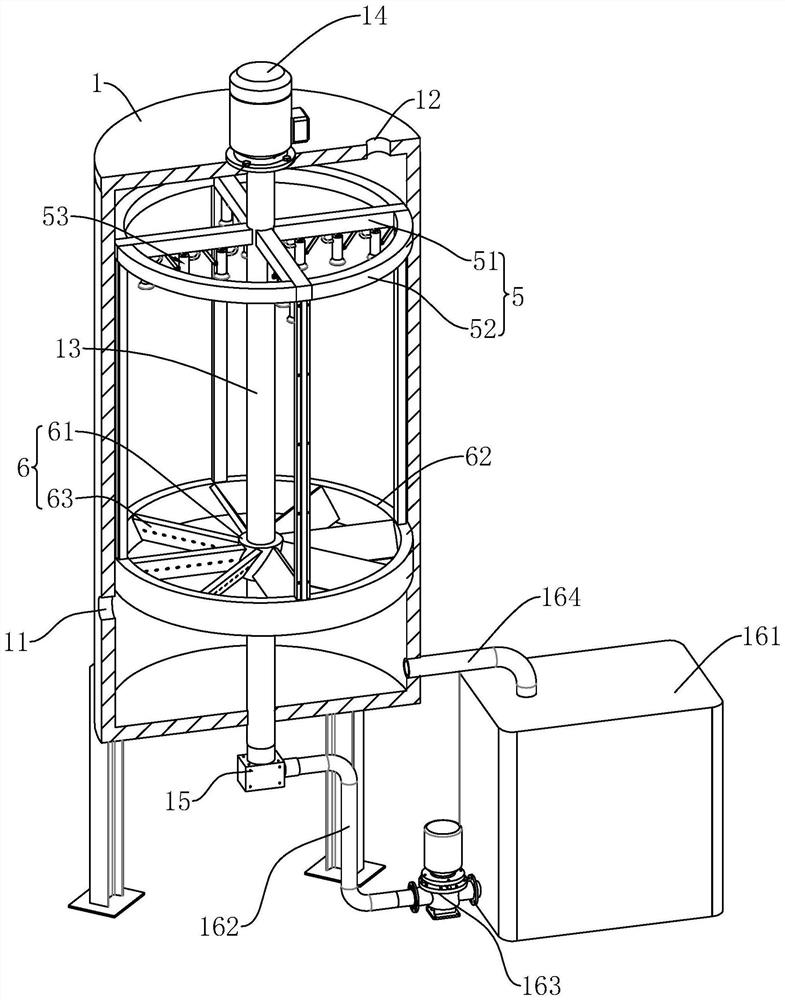

[0039] refer to figure 2 The lower part of the side wall of the spray tower 1 is penetrated with an air inlet 11 for the asphalt waste gas to pass through, and the top wall of the air inlet 11 is penetrated with an air outlet 12 for the dedusted asphalt waste gas to be discharged. Spray tower 1 is coaxially co...

Embodiment 2

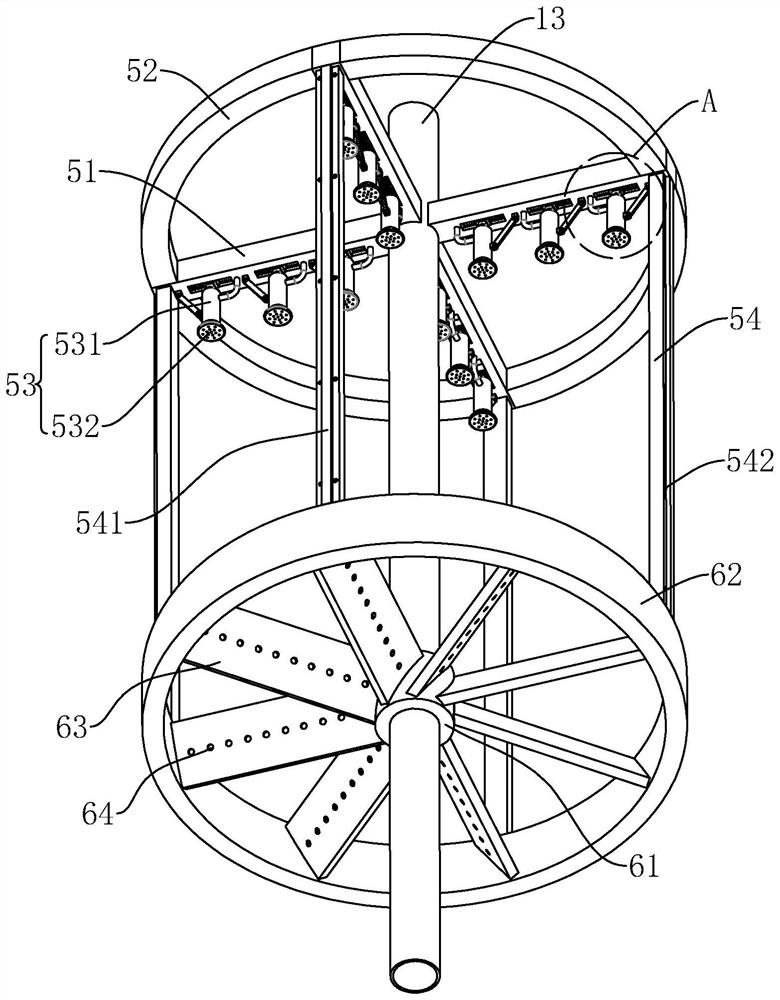

[0046] Embodiment 2: The difference with Embodiment 1 is that, with reference to Figure 5 , Image 6 , the driver 14 is an ordinary motor, the lower end surface of the mounting rod 51 is provided with a second chute 514 along its length direction, the mounting rod 51 is provided with a sliding plate 515 slidingly connected to the second chute 514, and a plurality of atomizing nozzles 53 is disposed on the sliding plate 515 . One end of the sliding plate 515 far away from the support pipe 13 is fixedly connected with a touch hemispherical head 55, and the touch hemispherical head 55 is located outside the installation rod 51, and the inner peripheral wall of the spray tower 1 is provided with an annular toothed belt groove 17, and the annular toothed belt groove 17 consists of continuous The wavy tooth grooves and tooth protrusions are formed, the actuating hemispherical head 55 is adapted to the tooth grooves of the annular toothed belt groove 17, and the inner wall of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com