Spraying device and evaporative cooling system

A spray device and spray pipe technology, applied in air conditioning systems, lighting and heating equipment, space heating and ventilation, etc., can solve the problem of large spray water flow, spray dead angle, increased structural complexity and spray cost And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Data center (DC) refers to the facilities used to house computer systems and related components, such as telecommunications, storage systems, power supply systems, data communication systems, environmental control systems (such as air conditioners, fire extinguishers) and various security equipment. Data centers are typically used to pass, accelerate, display, compute, and store data information on network infrastructure.

[0057] The various systems and equipment in the data center generate a lot of heat when they are running, and in order to keep the room temperature of the data center low to maintain the normal operation of each system, a refrigeration system is required to discharge the heat from the data center.

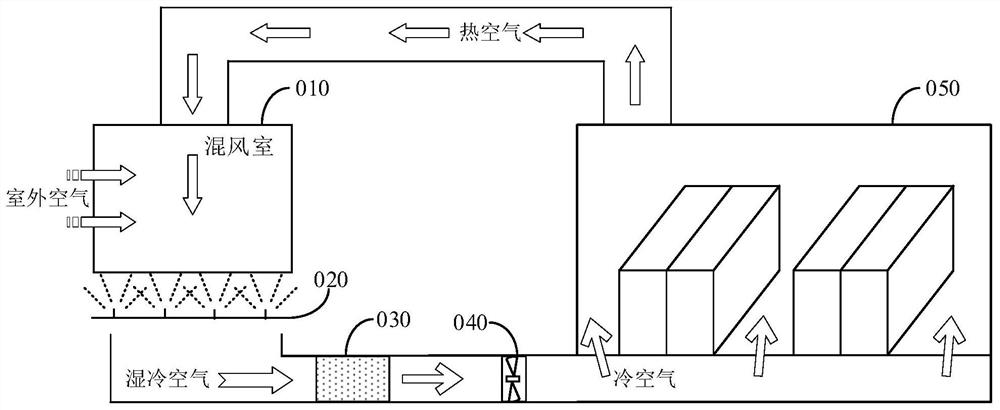

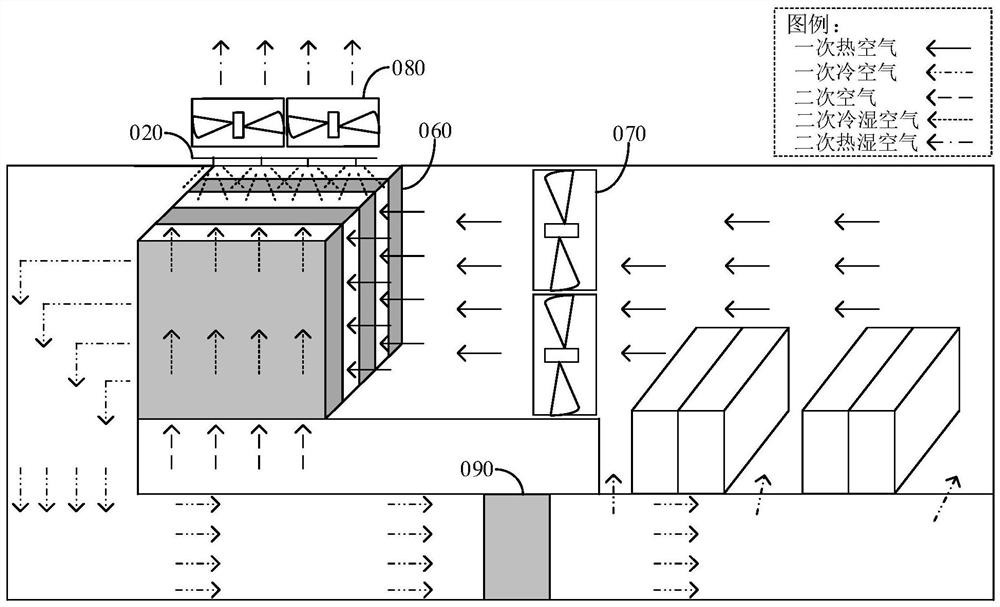

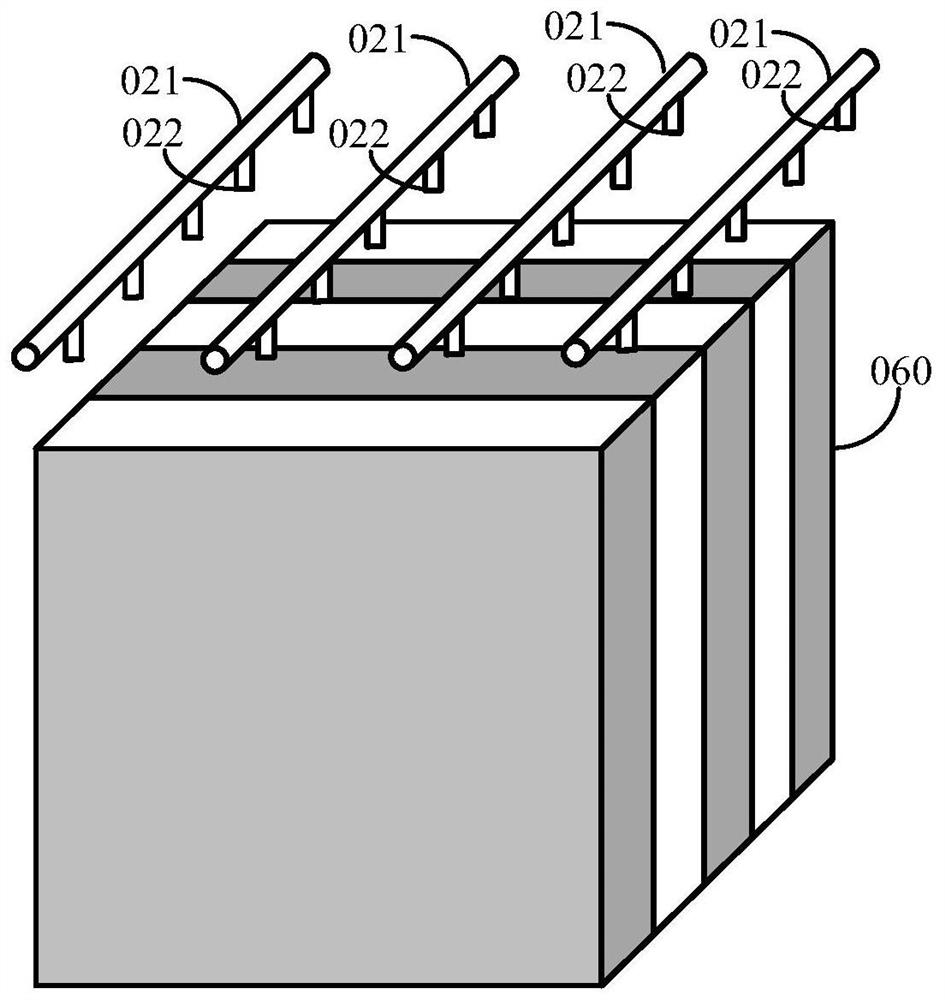

[0058] Currently, refrigeration systems in data centers can be achieved using evaporative cooling technology. Evaporative cooling technology refers to the use of water evaporation heat absorption characteristics to reduce the temperature of the data center. F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com