Container spraying process and spraying production line

A container and production line technology, which is applied in liquid spraying equipment, coatings, spray booths, etc., can solve the problems of staff health damage, easy spread of paint, environmental pollution, etc., to improve the quality of spraying, reduce dead spots of spraying, and improve spraying efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

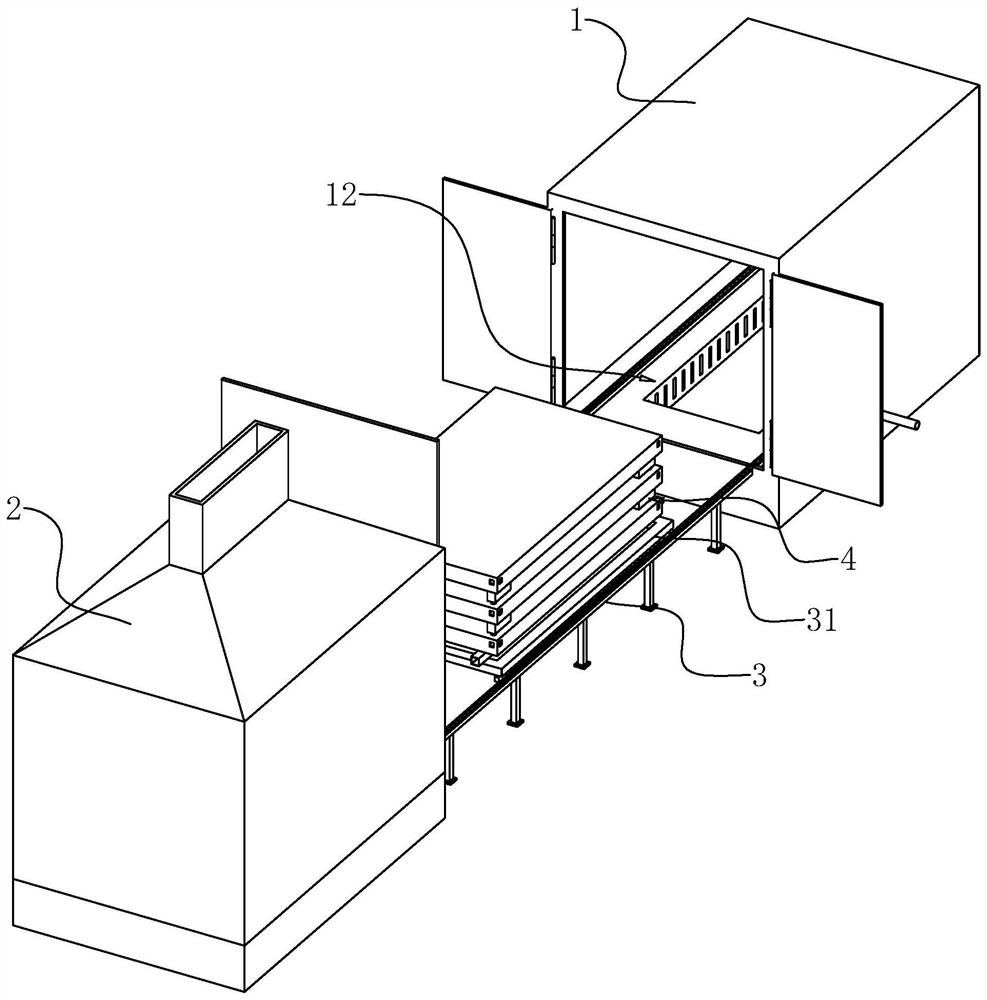

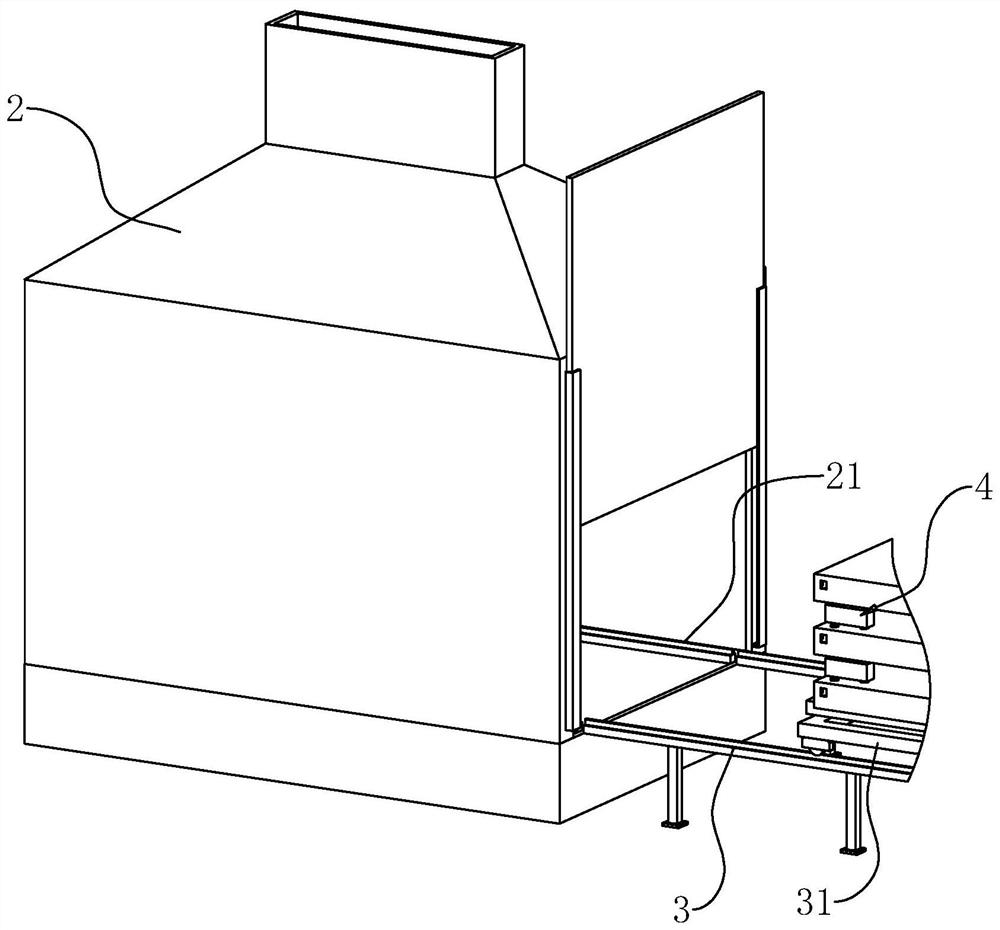

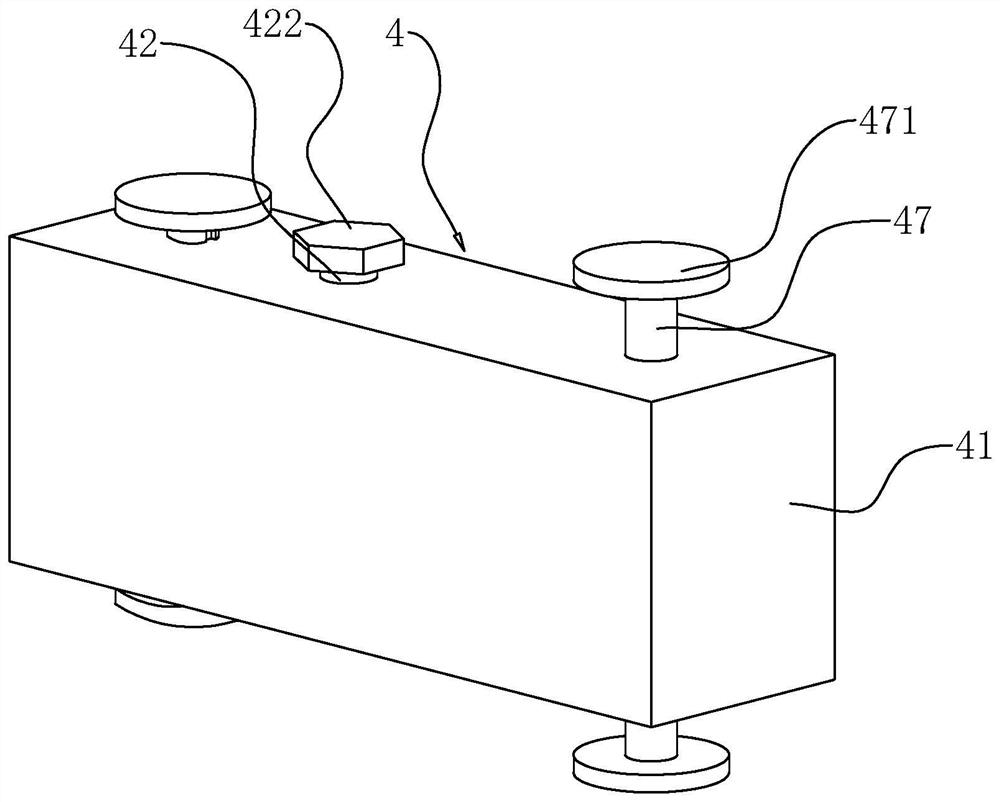

[0041] The following is attached Figure 1-5 The application is described in further detail.

[0042] The embodiment of the application discloses a container spraying process. refer to figure 1 , a container spraying process comprises the following steps:

[0043] Step S1: Put the various parts of the container including the bottom, top, end wall and side wall of the container into the spraying cabin 1;

[0044] Step S2: Spraying each component of the container in the spraying cabin 1, the spraying material is plastic powder, and spraying is carried out in a classical spraying method until a layer of protective paint is attached to the surface of each component of the container;

[0045] Step S3: Take out the various parts of the container from the spraying cabin 1 and transport them to the baking cabin 2, and use the heating equipment in the baking cabin 2 to bake the various parts of the container on the transportation platform, and the components in the baking cabin 2 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com