Hygrochromic/thermochromic composition and hygrochromic/thermochromic indicator

A composition and indicator technology, applied in the direction of color-changing fluorescent materials, chemical instruments and methods, analysis using chemical indicators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

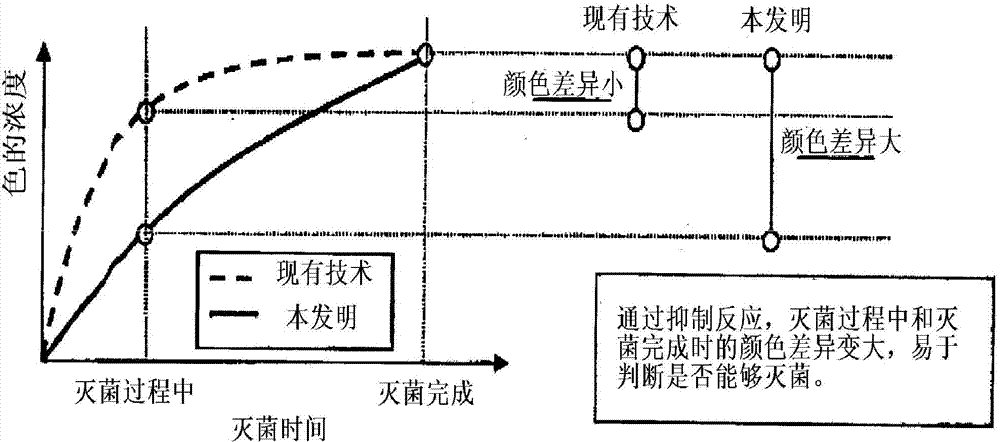

Problems solved by technology

Method used

Image

Examples

Embodiment 1~13 and comparative example 1~2

[0090] (Production of Moisture and Heat Discoloration Composition and Moisture and Heat Discoloration Indicator)

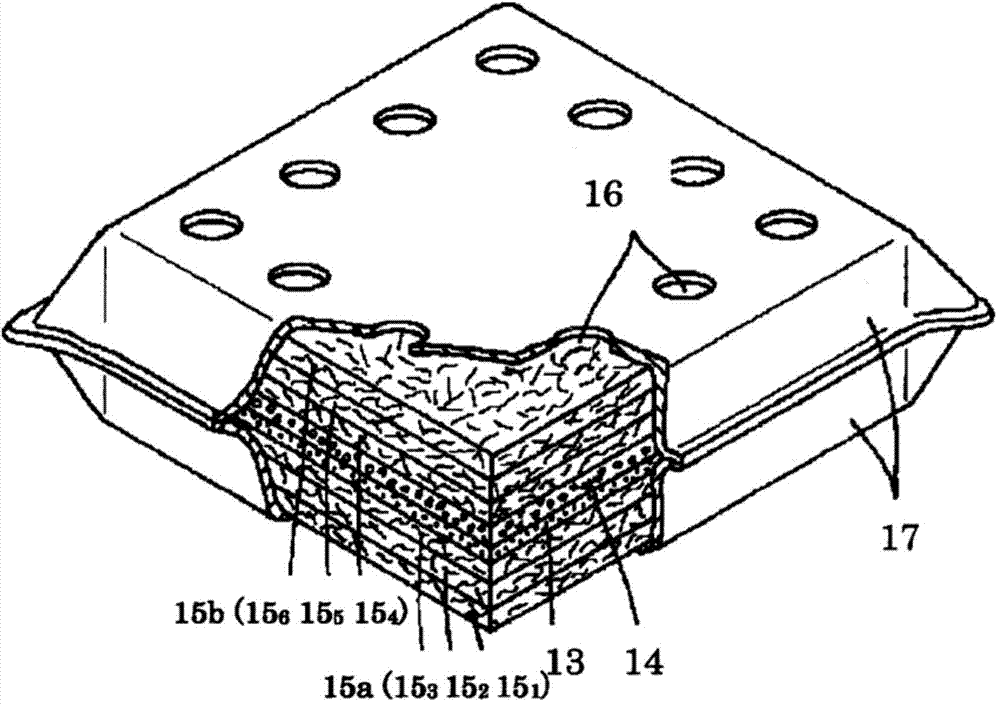

[0091] For the ingredients shown in Table 1, the organic solvent and binder were first stirred with a dissolver. When the binder is difficult to dissolve, it can be dissolved by heating. Then, add the remaining ingredients and stir well. In addition, a ball mill, a bead mill, etc. are used appropriately so that the target particle size of the bismuth compound is 0.2 μm, and the target particle size of the sulfide is 20 μm or less. Thus, 15 kinds of moist heat discoloration compositions (inks) of Examples 1 to 13 and Comparative Examples 1 to 2 were prepared. Use the above-mentioned inks to screen-print on high-grade paper with a 250-mesh screen to form color-changing layers.

[0092] [Table 1]

[0093]

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com