Copper alloy low-temperature cleaning agent

A cleaning agent and copper alloy technology, applied in the field of cleaning agents, can solve the problems of pollution, high cost, high cost, etc., and achieve the effect of environmental friendliness and good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with the examples, the present invention is further described, the following examples are illustrative, not limiting, and the protection scope of the present invention cannot be limited by the following examples.

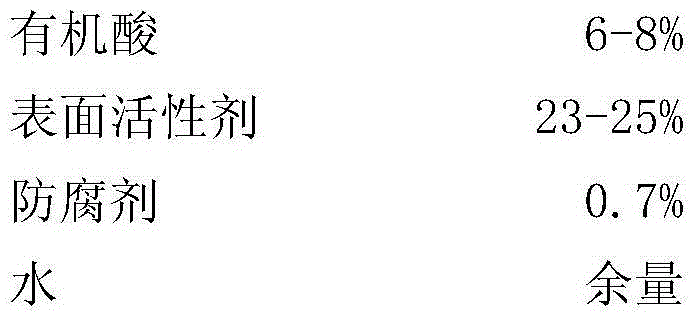

[0029] A copper alloy low-temperature cleaning agent, a mixture consisting of the following weight percentages

[0030]

[0031] Preparation:

[0032] (1) First mix and dissolve the anionic surfactant and nonionic surfactant with part of the water;

[0033] (2) Dissolve the additives and preservatives in some water;

[0034] (3) The dissolving solutions of step (1) and step (2) are mixed with the remaining water and mixed slowly to obtain the product.

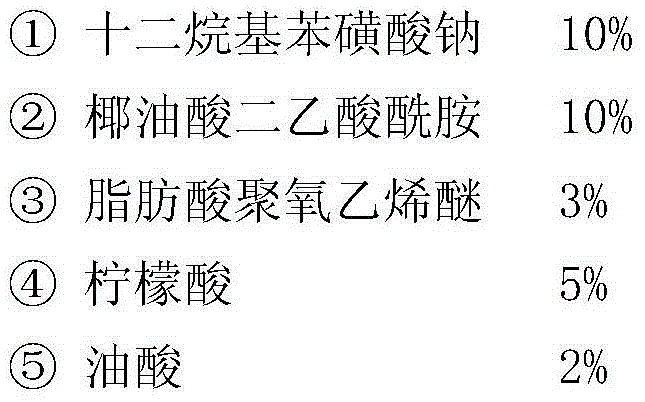

[0035] In order to clearly describe the present invention in detail, the following specific ingredients and proportions are provided.

[0036] The materials used in the present invention are all commercially available and do not require special treatment.

[0037] A copper alloy low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com