Panel pressing machine handpiece for multicolor panel pressing and panel pressing machine

A machine head and sheet feeding technology, which is applied to the mechanism of embroidery machines, embroidery machines, and automatic control embroidery machines, etc. It can solve problems such as shutdown replacement, collision of ironing sheet blanking holes, and bending of punching needle heads, etc., and achieves a compact structure. , The effect of ensuring reliability

Active Publication Date: 2020-08-25

ZHEJIANG XINSHENG SEWING EQUIP

View PDF5 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] Except that the needle bar frame itself guides the needle bar of the punching needle, the current punching needle usually passes directly through the blanking hole of the ironing sheet, punches the ironing sheet off the material belt, and completely separates from the material belt, and the punching needle and the ironing sheet fall off. It is not easy to guarantee the concentric requirements of the material hole and the hot plate

During the punching process, the punching needle is also likely to collide with the blanking hole of the ironing sheet, causing the head of the punching needle to bend, and must be stopped for replacement

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0094] A sheet ironing machine, comprising the needle bar frame type ironing machine head in the first embodiment above. The ironing machine can be equipped with a plurality of the above-mentioned ironing machine heads, and each ironing machine head can have a variety of ironing sheet specifications to choose from, which greatly enriches the diversity of pattern production.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

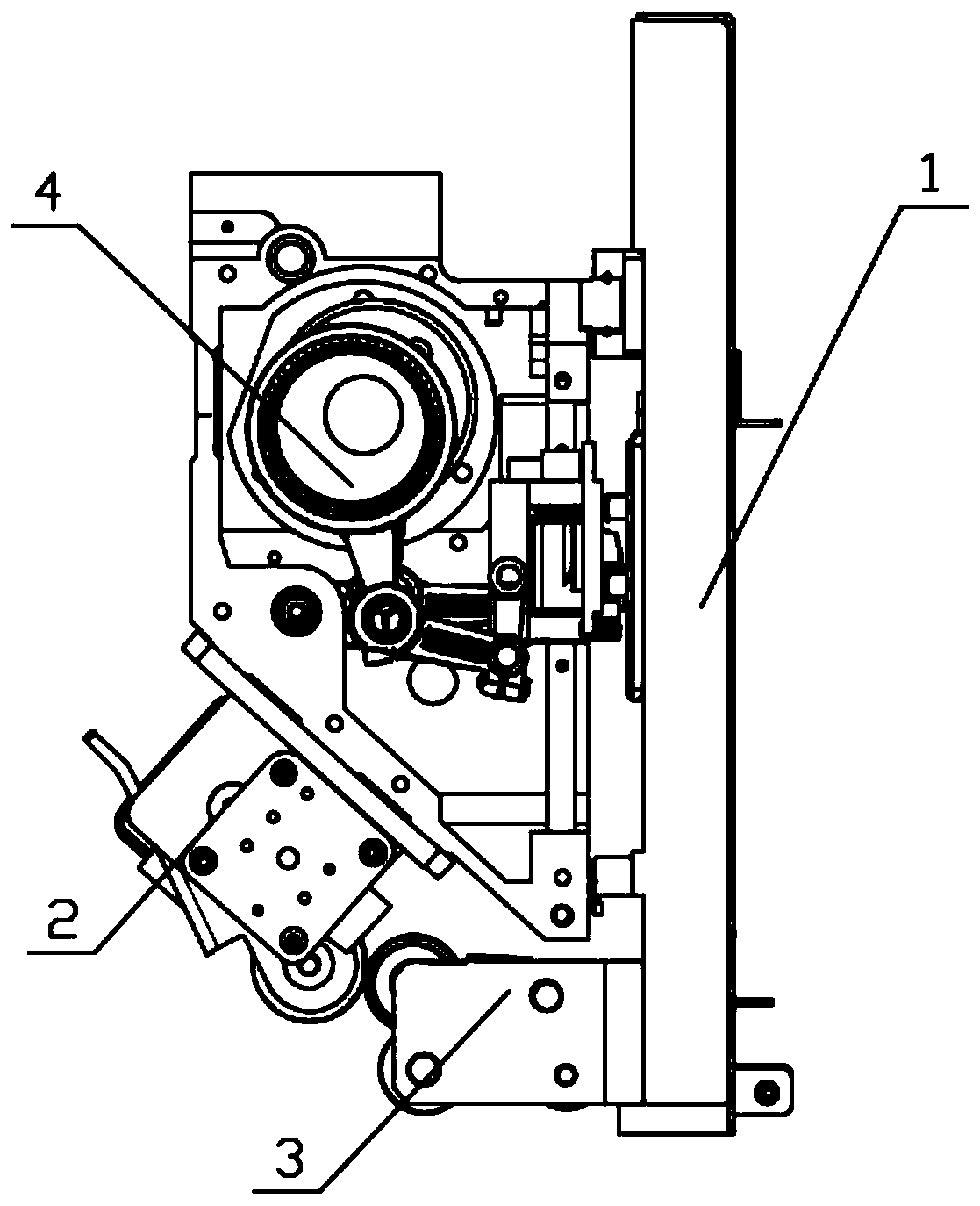

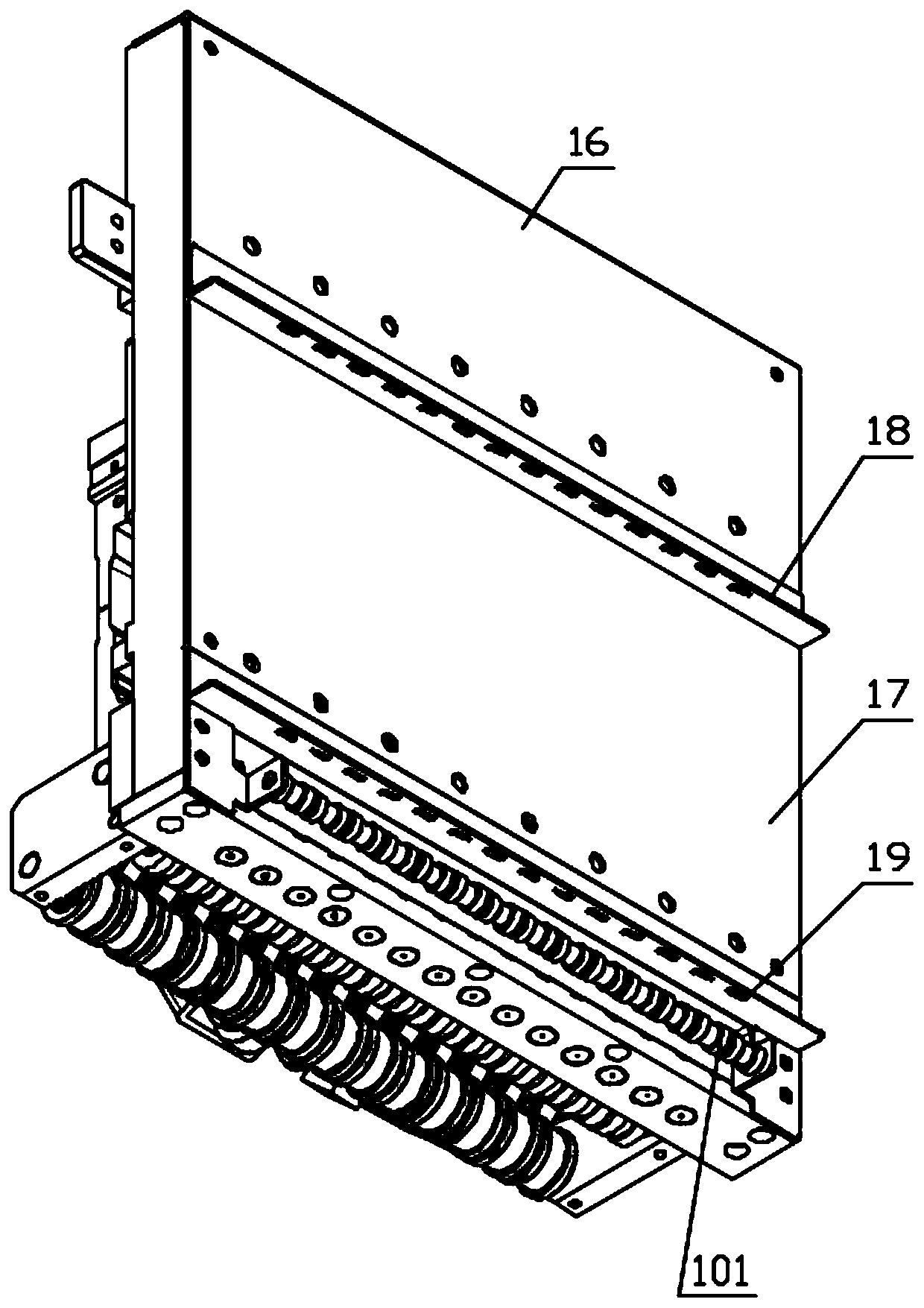

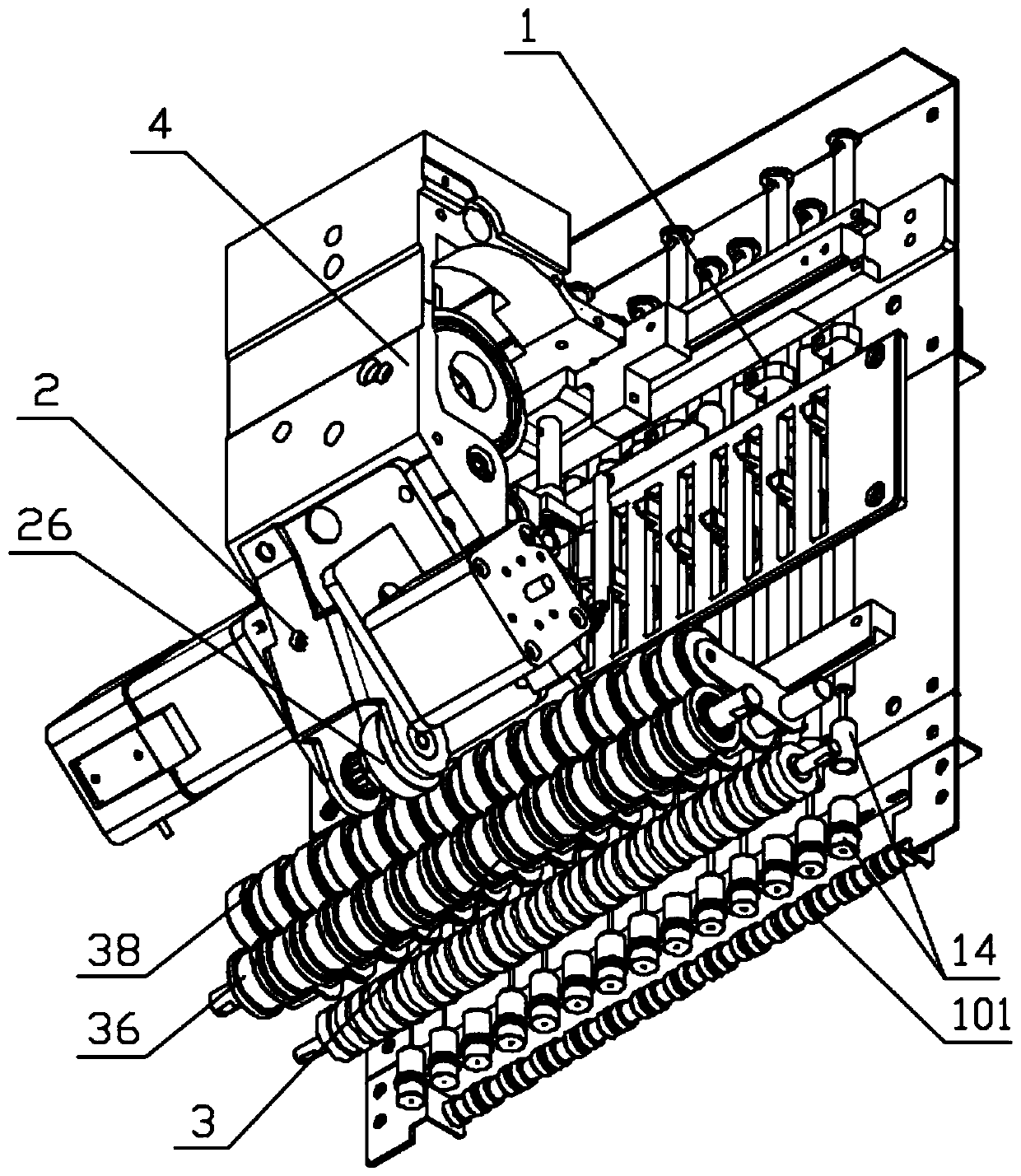

The invention discloses a panel pressing machine handpiece for multicolor panel pressing and a panel pressing machine. The handpiece comprises a needle bar frame and a handpiece shell, wherein the needle bar frame is provided with a row of punch needle bar assemblies in the width direction, and a belt performs conveying below the needle bar frame; each punch needle bar assembly comprises a punch needle bar and a punch needle mounted at the bottom of the punch needle bar, and the punch needles punch off pressed panels conveyed on the belt below; and a panel feeding roller assembly is mounted atthe rear side of the bottom of the needle bar frame, and a panel feeding driving assembly is mounted on the handpiece shell. The handpiece further comprises a color changing mechanism, wherein the color changing mechanism comprises a color changing guide rail and a color changing box assembly, the needle bar frame is connected with the color changing guide rail, and during color changing, the color changing box assembly drives the needle bar frame to move along the color changing guide rail to complete color changing. Through the handpiece, the demand for feeding the panels on multiple beltscan be met in a small space, the requirement for normal color changing is met, and the requirement for concentricity of the punch needles, pressed panel discharging holes and the pressed panels in theoperating process is met.

Description

technical field [0001] The invention belongs to the technical field of ironing machines. Background technique [0002] In the prior art, the ironing machine can iron fewer designs and colors. If you need to increase the design and color, you need to add a punching needle assembly on the ironing machine head, which will increase the volume of the ironing machine head and cannot be used in a limited space. Arrange more heads inside. [0003] Needle bar rack type ironing machine head, the needle bar frame structure of ordinary flat embroidery machine is modified, and the multi-punch needle bar components are installed side by side on the needle bar frame. Compared with the head of the conventional ironing machine, more punching needle bar assemblies can be arranged in a small space to increase the color of the ironing sheet. [0004] Corresponding to multiple punch needle bar assemblies, it is necessary to set up corresponding film feeding devices to meet the film feeding req...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): D05C7/08D05C13/00

CPCD05C7/08D05C13/00

Inventor 王海江田桂郁洪晓峰

Owner ZHEJIANG XINSHENG SEWING EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com