Toothpaste with low abrasion and high tooth cleaning effect

A low-wear, high-clean technology, applied in the field of high-clean tooth type abrasive composition toothpaste, low-abrasion, abrasive composition toothpaste, can solve the problems of tooth enamel wear, poor cleaning power of toothpaste, etc., achieves good tooth cleaning power, Quickly removes bad breath and avoids wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

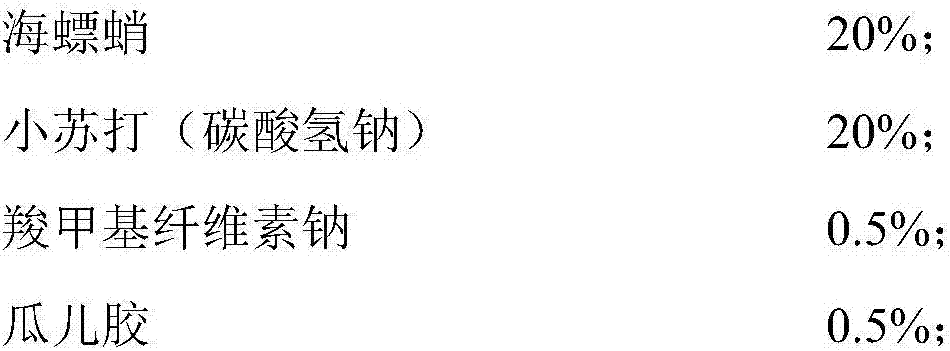

[0048] A toothpaste with low abrasion and high tooth cleaning effect, comprising the following raw material components by weight percentage:

[0049]

[0050]

[0051] The production process is as follows:

[0052] 1) Add parabens and essence into container A, stir to dissolve;

[0053] 2) Add deionized water into premixing pot B, then add sodium saccharin, zinc citrate, cocamidopropyl betaine and stir to dissolve;

[0054] 3) Add polyethylene glycol and sorbitol into the premixing pot C;

[0055] 4) Add squid octopus, baking soda (sodium bicarbonate), sodium carboxymethyl cellulose, guar gum, sodium lauryl sulfate, and titanium dioxide into the powder mixer;

[0056] 5) Inhale the liquid material in premixing pot B and premixing pot C into the paste making machine under vacuum, then start the scraper and stir to suck in the powder in the powder mixer, open the homogenizer after the powder is fed, Homogeneous degassing for 30 minutes;

[0057] 6) After vacuum degassi...

Embodiment 2

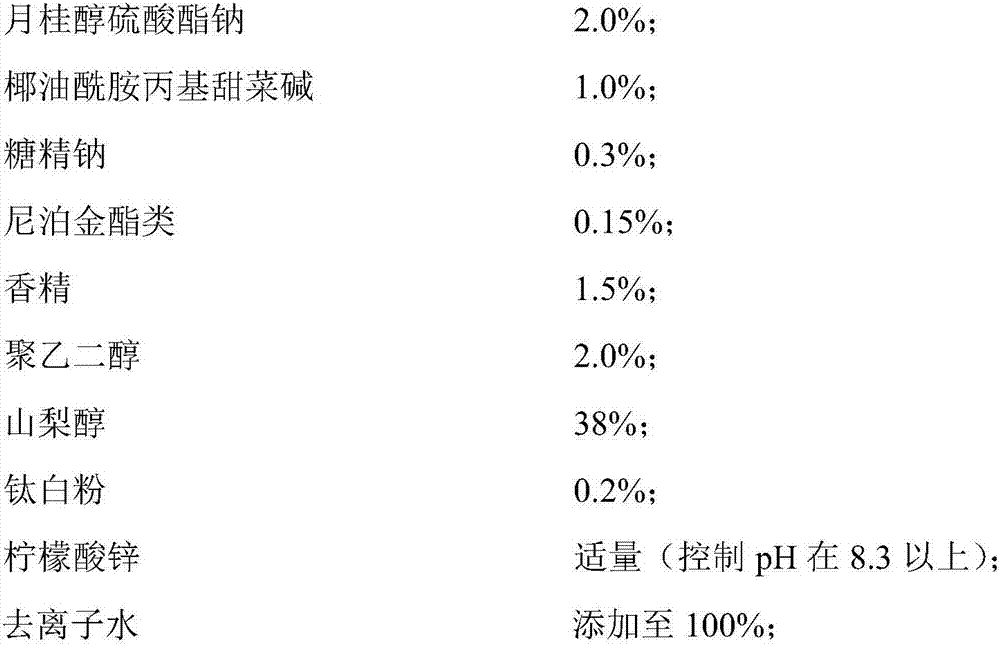

[0059] A toothpaste with low abrasion and high tooth cleaning effect, comprising the following raw material components by weight percentage:

[0060]

[0061]

[0062] The production process is as follows:

[0063] 1) Add parabens and essence into container A, stir to dissolve;

[0064] 2) Add deionized water into the premixing pot B, then add acesulfame K, neotame, zinc citrate, sodium lauroyl sarcosinate and stir to dissolve;

[0065] 3) Add polyethylene glycol and sorbitol into the premixing pot C;

[0066] 4) Add squid octopus, baking soda (sodium bicarbonate), sodium carboxymethyl cellulose, xanthan gum, sodium lauryl sulfate, and titanium dioxide into the powder mixer;

[0067] 5) Inhale the liquid material in premixing pot B and premixing pot C into the paste making machine under vacuum, then start the scraper and stir to suck in the powder in the powder mixer, open the homogenizer after the powder is fed, Homogeneous degassing for 30 minutes;

[0068] 6) Afte...

Embodiment 3

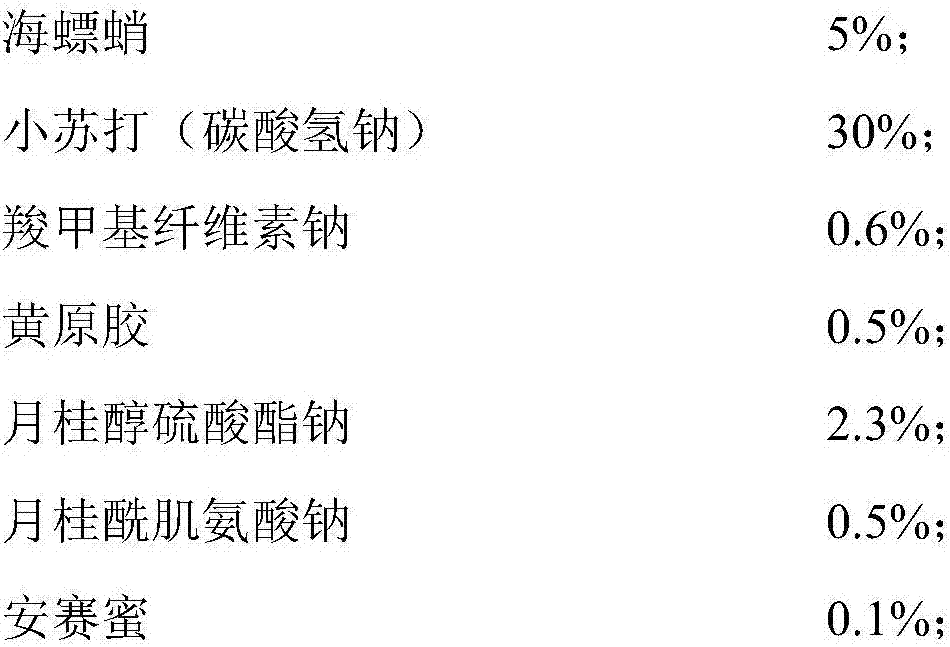

[0070] A toothpaste with low abrasion and high tooth cleaning effect, comprising the following raw material components by weight percentage:

[0071]

[0072]

[0073] The production process is as follows:

[0074] 1) Add deionized water into premixing pot B, then add sodium saccharin, sodium benzoate and zinc citrate and stir to dissolve;

[0075] 2) Add propylene glycol, glycerin and sorbitol into the premixing pot C;

[0076] 3) Add squid octopus, baking soda (sodium bicarbonate), sodium carboxymethyl cellulose, xanthan gum, sodium lauryl sulfate, and titanium dioxide into the powder mixer;

[0077] 4) Inhale the liquid material in premixing pot B and premixing pot C into the paste making machine under vacuum, then start the scraper and stir to suck the powder in the powder mixer, open the homogenizer after the powder is fed, Homogeneous degassing for 30 minutes;

[0078] 5) After vacuum degassing for 30 minutes, inhale the essence, then homogenize and degas for 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com