Colour-changer

A color changer and valve device technology, applied in the field of color changers, can solve the problems of difficulty in detecting valve device leakage, unusable paint results, and the interconnection of atomizers is not always feasible, and achieves the effect of compact arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

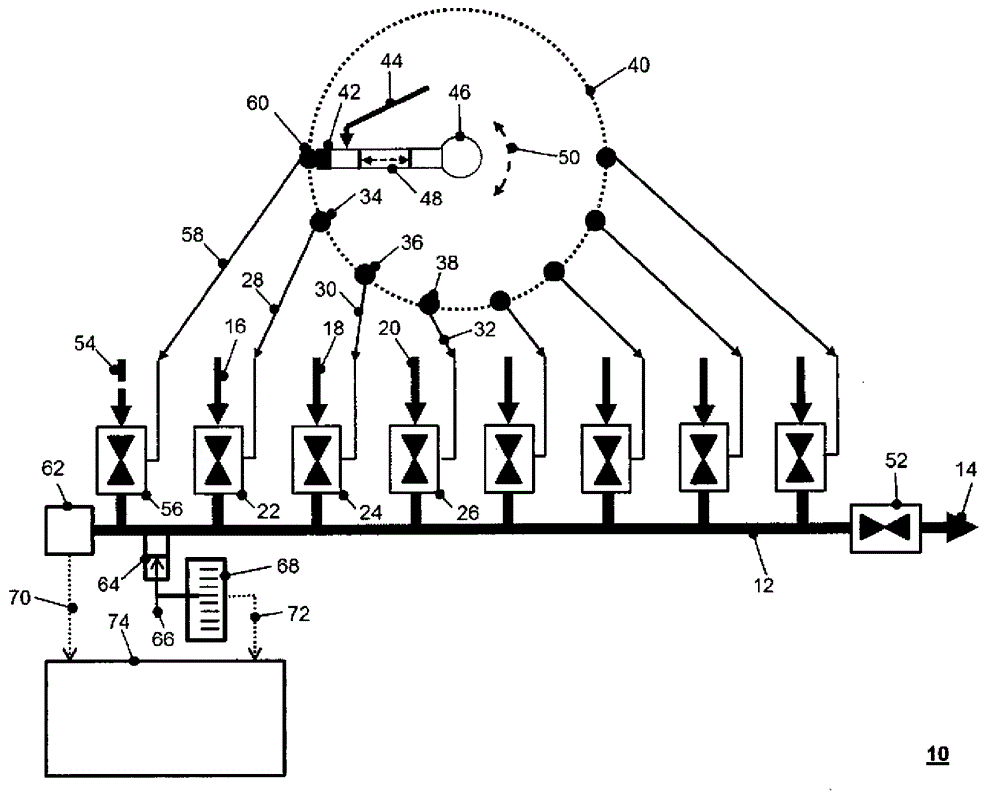

[0034] figure 1 An exemplary color changer 10 is shown in a schematic diagram. Paint supply channels 16 , 18 , 20 lead to output channel 12 . Each of the paint supply channels 16, 18, 20 can be switched on and off by respective valve means 22, 24, 26 which are closed in their normal state and can be opened by applying pressure on the respective pressure lines 28, 30, 32. (such as air pressure) to operate the corresponding valve device.

[0035] With one of the valve means 22, 24, 26 actuated and open, paint material from a not shown paint supply system flows into the output channel 12 and from there through the second valve means 52, through the output 14 to Paint atomizer not shown. The second valve means 52 makes it possible to close the output 14 so that paint cannot flow to the atomizer when the second valve means 52 is in the closed state, as required eg during a color change or cleaning process. This cleaning process should be done before filling the output channel 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com