Transformer oil and preparation method thereof

A technology of transformer oil and paraffin-based oil, which is applied in the chemical field and can solve problems such as easy generation of sludge, poor anti-oxidation performance, and short storage time of transformer oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

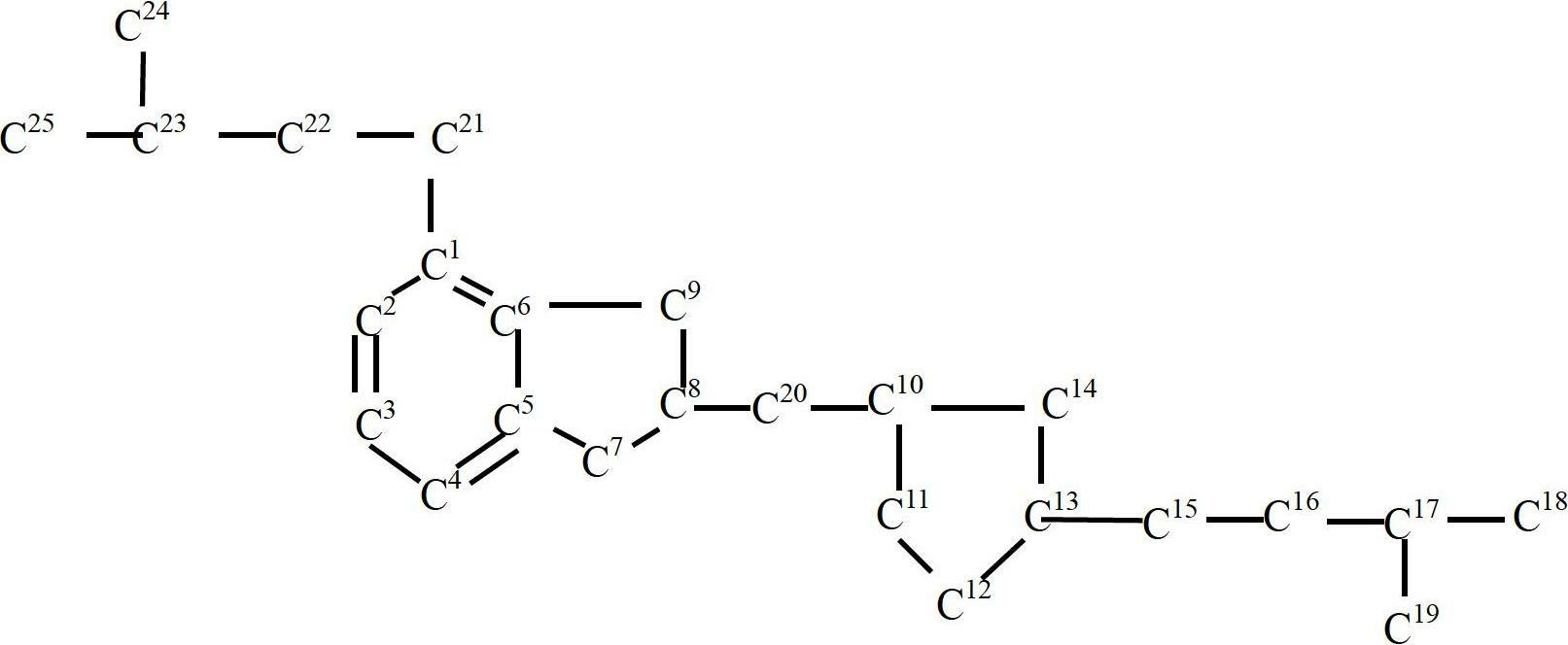

Method used

Image

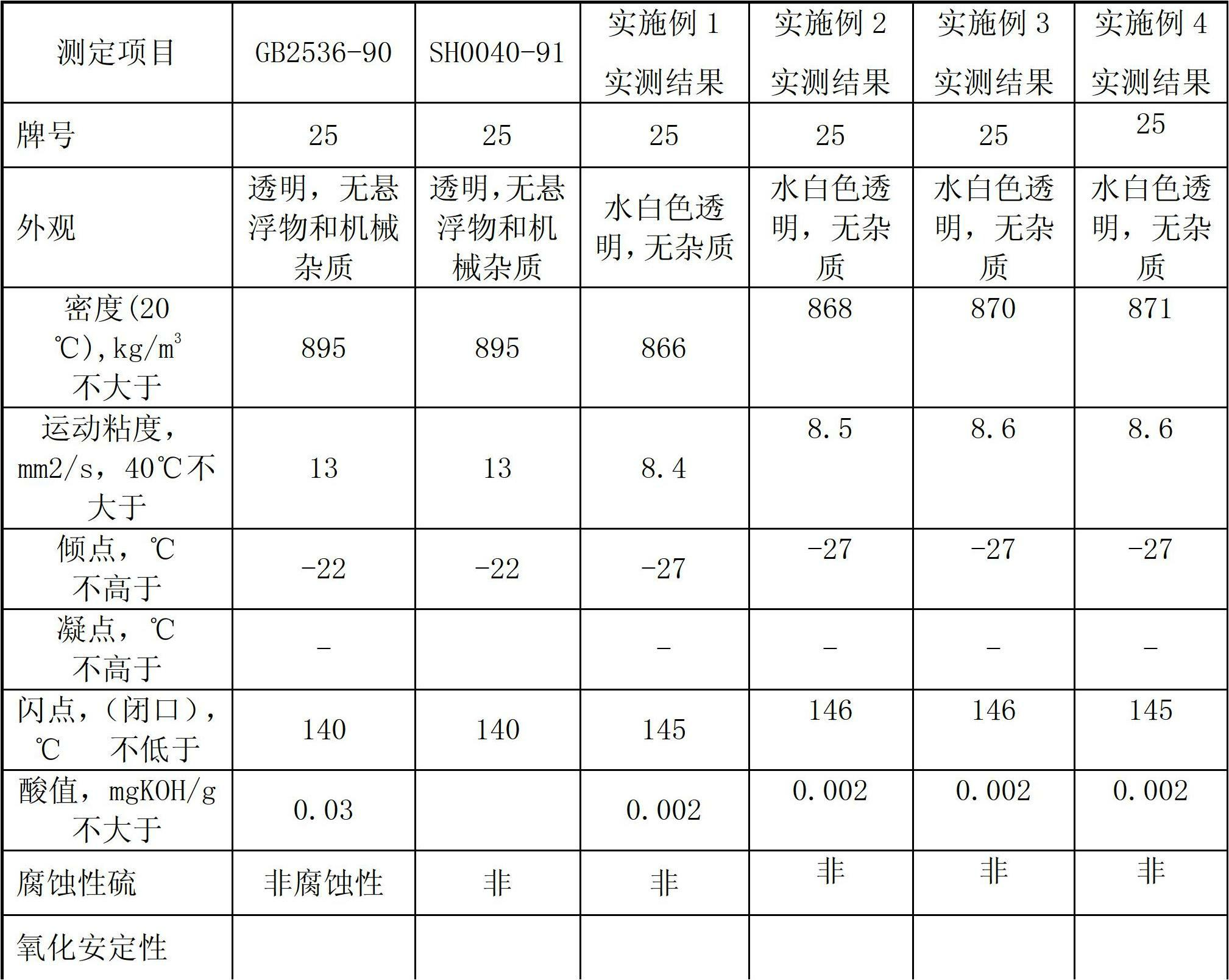

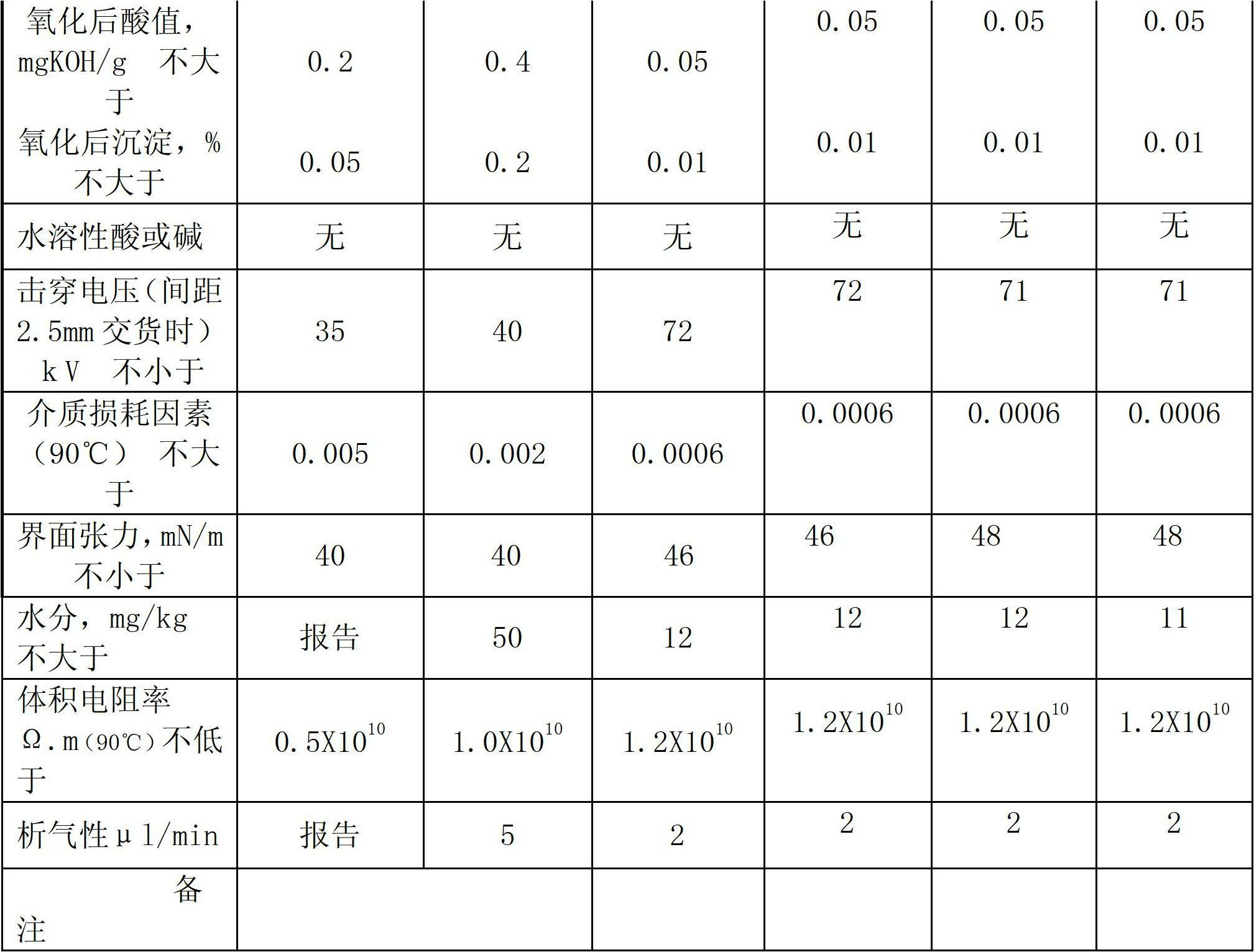

Examples

Embodiment 1

[0031] The invention provides a transformer oil, which is composed of paraffin base oil fractions, naphthenic oil fractions, alkyl high boilers, antioxidant additives, and anti-photosensitizers that are subjected to catalytic cracking of petroleum. The mass percentage of paraffin base oil fraction in the described transformer oil is 60%, the mass percentage of the described naphthenic oil in the described transformer oil is 28.5%, and the described alkyl high boiler is in the described The mass percentage of the transformer oil is 10%, and it is refined by adding clay with a weight percentage of 2% of the transformer oil at a temperature of 110°C. At the same time, it is stirred, refined and adsorbed for 40 minutes until the adsorption reaction is uniform, and the precipitate is filtered twice by a filter. The mass percentage of the anti-oxidant additive in the transformer oil is 1.0%, the mass percentage of the anti-light sensitive agent in the transformer oil is 0.5%, and the...

Embodiment 2

[0040] The invention provides a transformer oil, which is composed of paraffin base oil fractions, naphthenic oil fractions, alkyl high boilers, antioxidant additives, and anti-photosensitizers that are subjected to catalytic cracking of petroleum. The mass percentage of the paraffin base oil fraction in the transformer oil is 65%, the mass percentage of the naphthenic oil in the transformer oil is 25%, and the alkyl high boilers in the transformer oil The mass percentage in the oil is 9%, and at a temperature of 115°C, it is refined by adding clay with a weight percentage of 3wt% of transformer oil, and at the same time, it is stirred, refined and adsorbed for 40 minutes until the adsorption reaction is uniform. The mass percent of the anti-oxidant additive in the transformer oil is 0.6%, the mass percent of the anti-light sensitive agent in the transformer oil is 0.4%, and the vacuum pump cycle vacuum negative pressure is 0.8KPa for 2 times .

[0041] Further, the paraffin ...

Embodiment 3

[0049] The invention provides a transformer oil, which is composed of paraffin base oil fractions, naphthenic oil fractions, alkyl high boilers, antioxidant additives, and anti-photosensitizers that are subjected to catalytic cracking of petroleum. The mass percentage of the paraffin base oil fraction in the transformer oil is 70%, the mass percentage of the naphthenic oil in the transformer oil is 22%, and the alkyl high boilers in the transformer oil The mass percentage in the oil is 7%, and at a temperature of 120°C, it is refined by adding clay with a weight percentage of 4wt% to transformer oil, and at the same time, it is stirred, refined and adsorbed for 50 minutes until the adsorption reaction is uniform. The mass percent of the anti-oxidant additive in the transformer oil is 0.8%, the mass percent of the anti-light sensitive agent in the transformer oil is 0.2%, and the vacuum pump cycle vacuum negative pressure is 0.8KPa for 3 times .

[0050] Further, the paraffin ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Activity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com