High-flash-point low-condensation-point transformer oil and preparation method thereof

A technology of transformer oil and low freezing point, applied in the petroleum industry, lubricating composition and other directions, can solve the problems of poor gassing property and low flash point of transformer oil, and achieve the effect of improving insulation capacity, high safety performance and low freezing point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

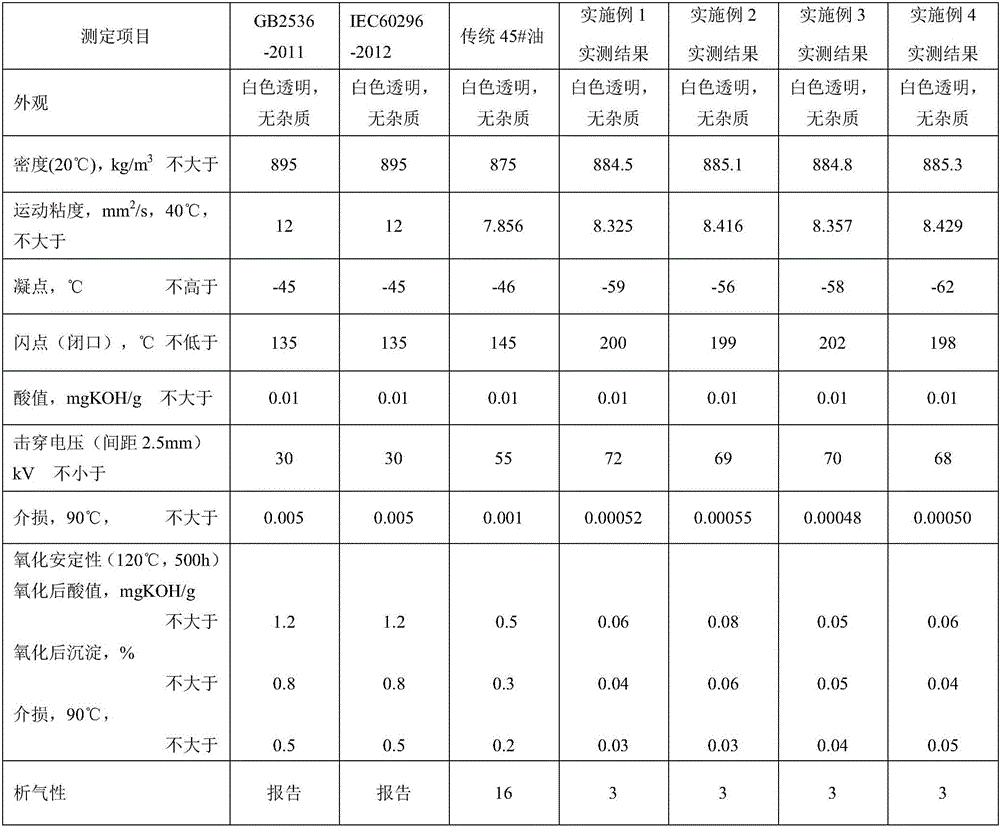

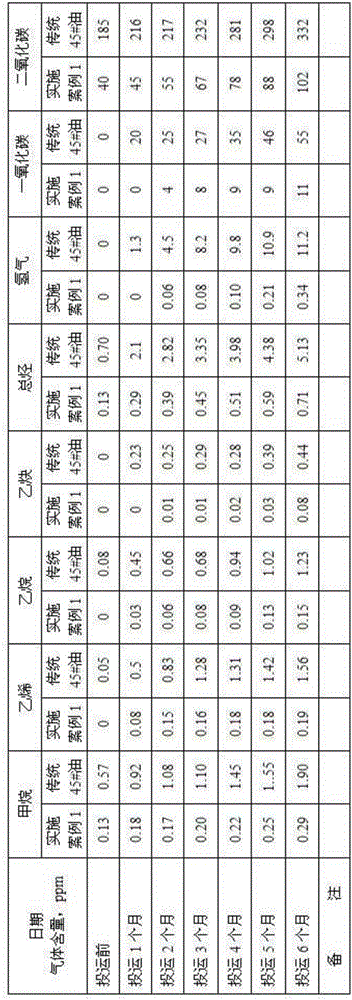

Examples

Embodiment 1

[0031] The invention provides a transformer oil with high flash point and low freezing point, which is composed of naphthenic oil with narrow fraction, antioxidant, pour point depressant, light sensitive agent and metal passivator. The weight percent of the narrow fraction naphthenic oil in the transformer oil is 97%. Put the naphthenic oil into the distillation tower and carry out atmospheric and vacuum distillation. The distillate oil at ~350°C is then subjected to hydrofining. During the hydrofinishing process, the reaction pressure of the reactor is 12MPa, the reaction temperature is 320°C, the total space velocity of oil feed is 0.5 / h, and the volume ratio of hydrogen to oil is 850. Relative to the hydrotreating catalyst space velocity of 0.65 / h, relative to the hydrotreating catalyst space velocity of 1.5 / h, the catalyst in the hydrotreating process is Mo-W / Al 2 o 3 , to obtain narrow cut naphthenic oil.

[0032] Take narrow-cut naphthenic oil, antioxidant, pour point ...

Embodiment 2

[0041] The invention provides a transformer oil with high flash point and low freezing point, which is composed of naphthenic oil with narrow fraction, antioxidant, pour point depressant, light sensitive agent and metal passivator. The weight percent of the narrow fraction naphthenic oil in the transformer oil is 98%. Put the naphthenic oil into the distillation tower and carry out atmospheric and vacuum distillation. The distillate oil at ~350°C is then subjected to hydrofining. During the hydrofining process, the reaction pressure of the reactor is 10MPa, the reaction temperature is 350°C, the total space velocity of the oil feed is 0.45 / h, and the reaction hydrogen oil volume ratio is 900. Relative to the hydrotreating catalyst space velocity of 0.7 / h, relative to the hydrotreating catalyst space velocity of 1.2 / h, the catalyst in the hydrotreating process is Co-Mo-W / Al 2 o 3 , to obtain narrow cut naphthenic oil.

[0042] Take narrow-cut naphthenic oil, antioxidant, pour...

Embodiment 3

[0051] The invention provides a transformer oil with high flash point and low freezing point, which is composed of naphthenic oil with narrow fraction, antioxidant, pour point depressant, light sensitive agent and metal passivator. The weight percent of the narrow fraction naphthenic oil in the transformer oil is 97.5%. Put the naphthenic oil into the distillation tower and carry out atmospheric and vacuum distillation. The distillate oil at ~350°C is then subjected to hydrofining. During the hydrofinishing process, the reaction pressure of the reactor is 15MPa, the reaction temperature is 330°C, the total space velocity of oil feed is 0.55 / h, and the volume ratio of hydrogen to oil is 930. Relative to the hydrotreating catalyst space velocity of 0.75 / h, relative to the hydrotreating catalyst space velocity of 1.2 / h, the catalyst in the hydrotreating process is Ni-W-Co / Al 2 o 3 , to obtain narrow cut naphthenic oil.

[0052] Take narrow-cut naphthenic oil, antioxidant, pour ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com