Inertial mass type vibration isolation device

An inertial mass and vibration isolation technology, which is applied to power plants, jet propulsion devices, internal combustion propulsion devices, etc., can solve the problems of poor shock resistance, high driving voltage, and cannot suppress resonance of the body shell, and achieves convenient maintenance and cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

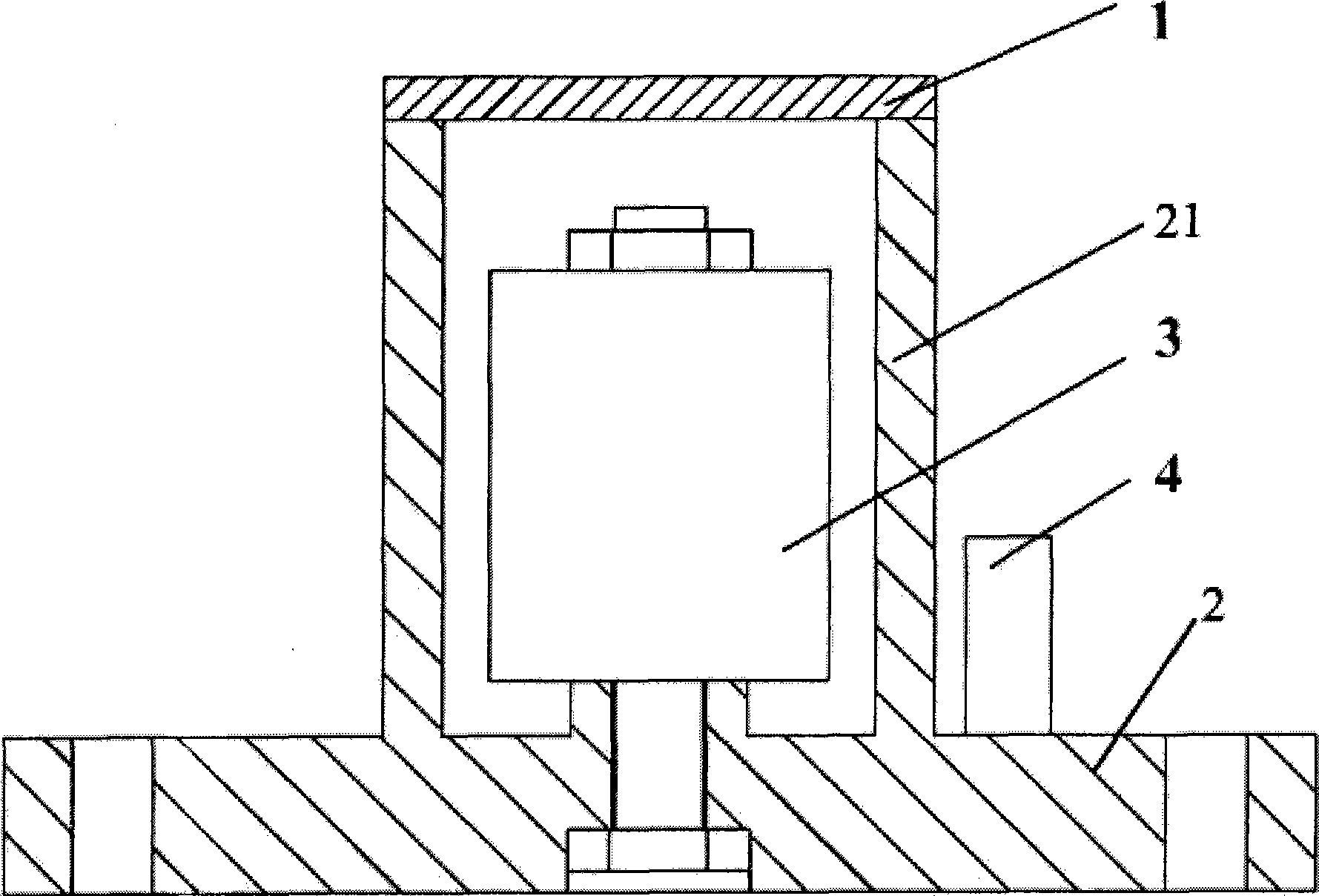

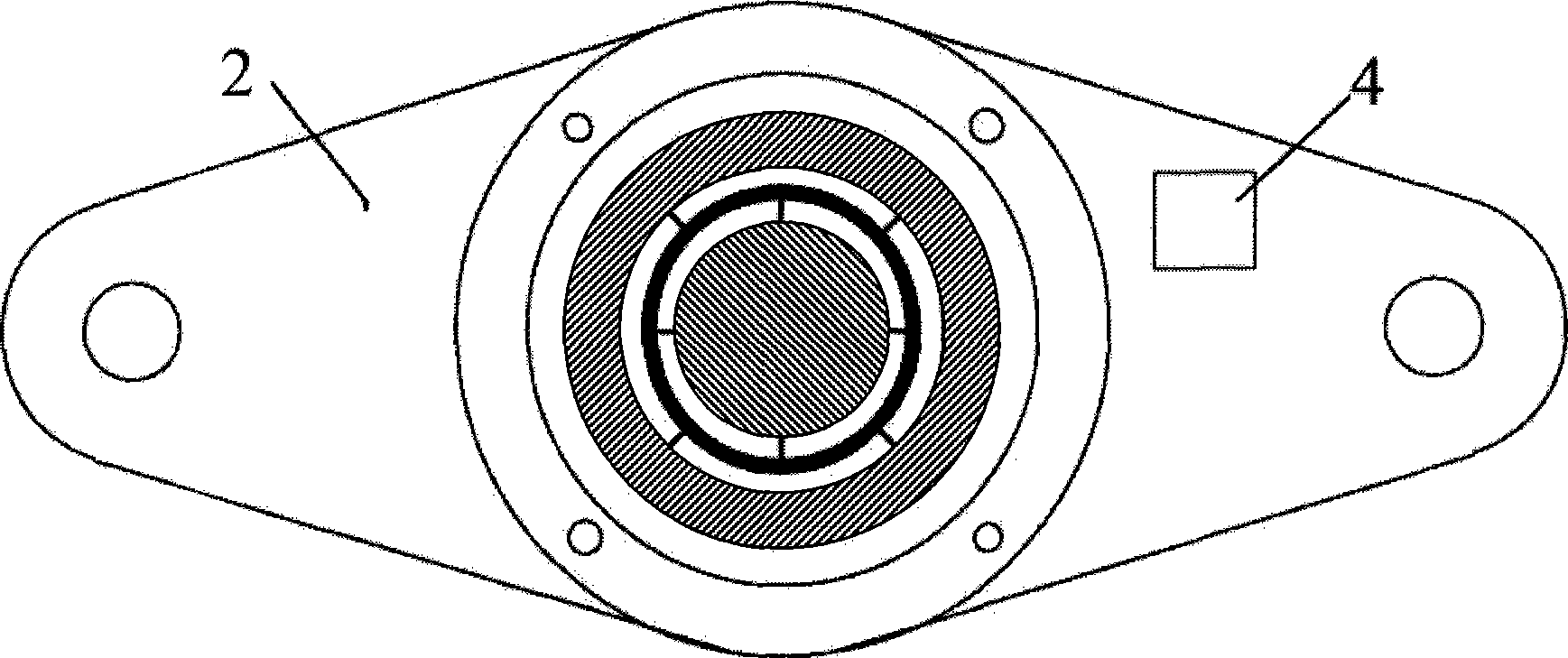

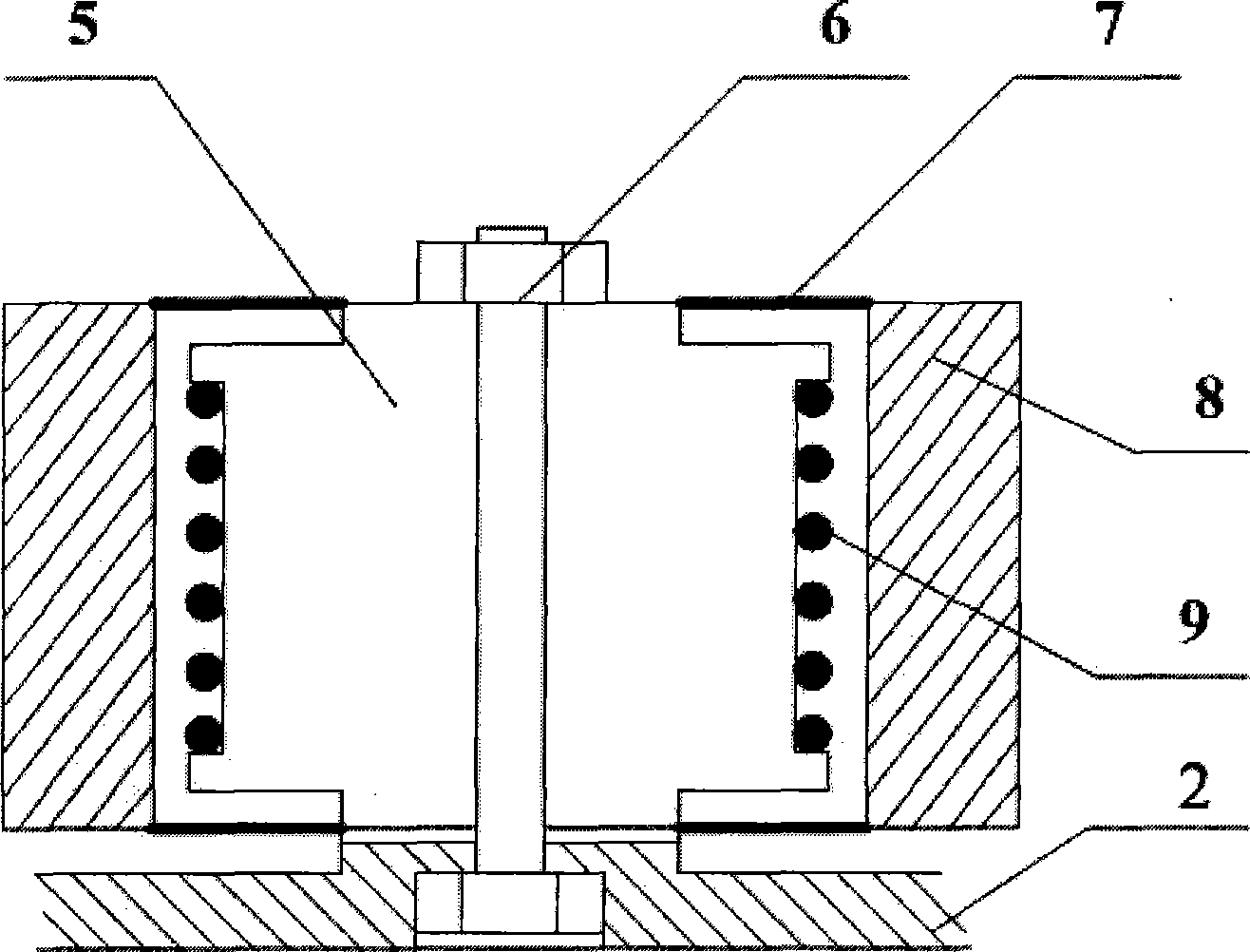

[0016] Such as figure 1 , figure 2 and image 3 As shown, the inertial mass type vibration isolation device of the present invention is composed of an anti-magnetic flux leakage enclosure 21, an upper cover 1, an inertial mass type electromagnetic actuator 3 and an acceleration sensor 4, wherein the lower end of the anti-magnetic flux leakage enclosure 21 A base 2 is provided, the upper cover 1 is arranged on the upper end of the magnetic flux leakage prevention housing 21, the inertial mass type electromagnetic actuator 3 is arranged in the magnetic flux leakage prevention housing 21, and the inertial mass type electromagnetic actuator 3 A stainless steel bolt 6 is fixedly connected to the base 2, the acceleration sensor 4 is arranged on the base 2, the signal output end of the acceleration sensor 4 is connected to a controller (not shown in the figure), and the inertial mass type electromagnetic action The coil of the actuator 3 is connected with a power amplifier (not sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com