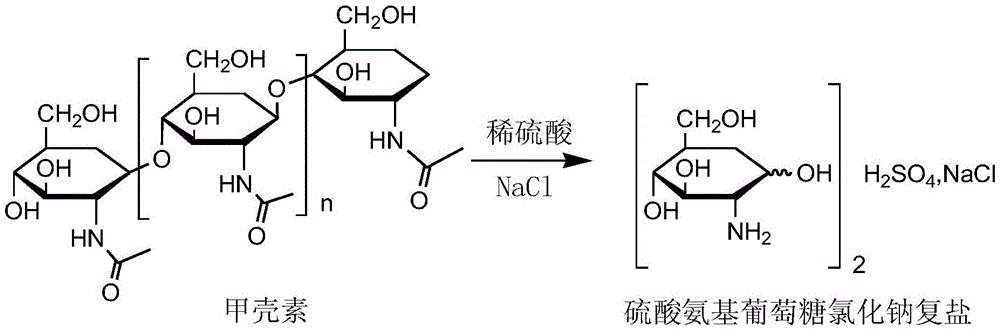

Preparation method of glucosamine sulfate and sodium chloride double salt

A technology of glucosamine sulfate and sodium chloride is applied in the field of medicine and chemical industry, and can solve the problems of low concentration of glucosamine, easy moisture absorption of finished products, high production difficulty, etc., and achieve the effects of simple process, improved product yield and high product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

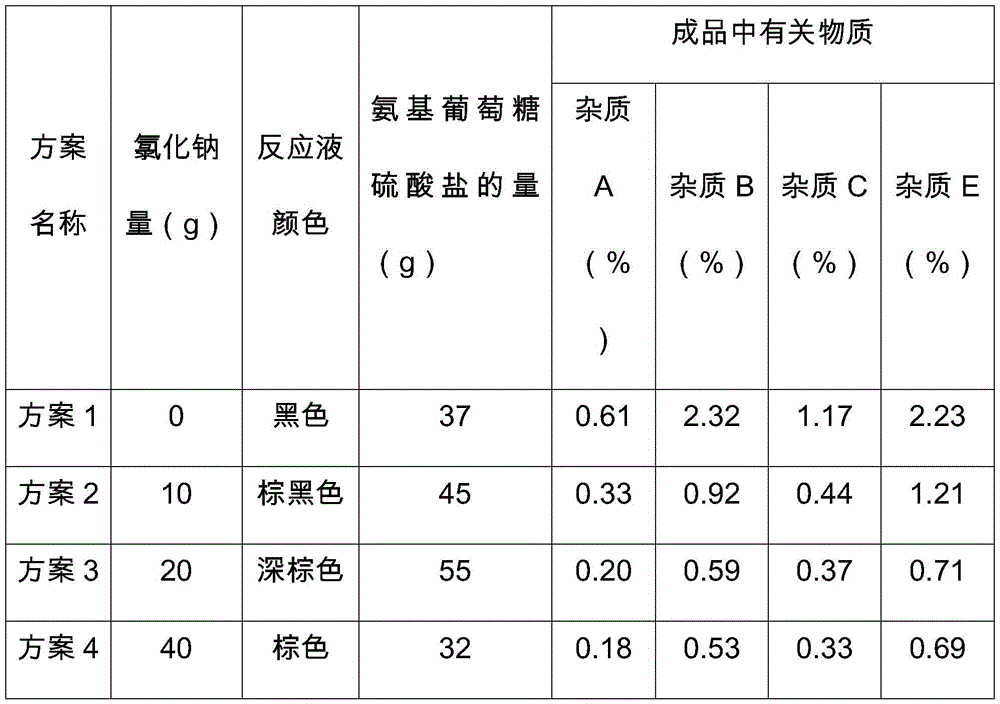

[0049] The Effect of Sodium Chloride on the Hydrolysis of Chitin

[0050] plan 1:

[0051] Add 100g of chitin and 600mL of 60% sulfuric acid into the three-neck flask, raise the temperature to 55°C, keep the temperature for 4h, do not add sodium chloride as a stabilizer, continue to heat up to 70°C for 1h, and then quickly drop the reaction solution to 50°C, then At this time, about 5% of chitin was still unreacted and dissolved, and 10 g of activated carbon and 15 g of diatomaceous earth were added to decolorize for 0.5 h. Pad diatomaceous earth to filter, measure the amount of glucosamine sulfate and the situation of related substances in the filtrate.

[0052] Scenario 2:

[0053] Add 100g of chitin and 600mL of 60% sulfuric acid into the three-neck flask, raise the temperature to 55°C, keep the temperature for 4h, add 10g of sodium chloride as a stabilizer, continue to heat up to 70°C for 1h, then quickly drop the reaction solution to 50°C, then At this time, about 5% o...

Embodiment 2

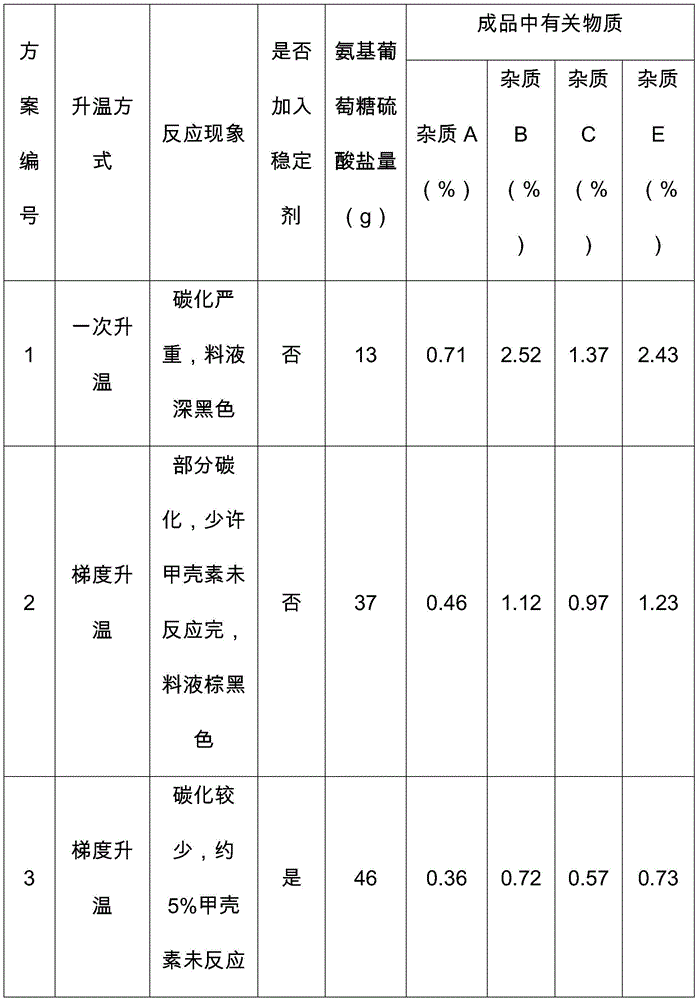

[0063] Influence of one-time high temperature and gradient temperature rise on acid hydrolysis reaction

[0064] plan 1:

[0065] Add 100g of chitin and 500mL of 70% sulfuric acid into the three-neck flask, raise the temperature to 75°C, keep it warm for 6h, then quickly lower the reaction solution to 50°C, add 15g of activated carbon, 15g of diatomaceous earth, and decolorize for 0.5h. Pad diatomaceous earth to filter, measure the amount of glucosamine sulfate and the situation of related substances in the filtrate.

[0066] Scenario 2:

[0067] Add 100g of chitin and 500mL of 70% sulfuric acid into the three-neck flask, raise the temperature to 55°C, keep it warm for 4h, continue to heat up to 75°C for 2h, then quickly lower the reaction solution to 50°C, add 15g of activated carbon, 15g of diatomaceous earth, decolorize 0.5h. Pad diatomaceous earth to filter, measure the amount of glucosamine sulfate and the situation of related substances in the filtrate.

[0068] Opti...

Embodiment 3

[0075] Put 500g of chitin and 3.5kg of 50% sulfuric acid into the reaction kettle, heat up to 55°C, keep warm for 5h, add 100g of sodium chloride, continue to heat up to 70°C for 1.5h, and then quickly drop the reaction solution to 50°C, at this time , Chitin still has about 8% unreacted and dissolved, add 250g of activated carbon, 250g of diatomaceous earth, and decolorize for 0.5h. Pad Celite to filter, transfer the filtrate to another kettle, quantitatively add 50g of sodium chloride, heat up to 50°C, stir and dissolve until clear, keep warm for 1h, and then cool down to room temperature. Divide the feed solution into 10 equal parts, number from 1 to 10, add ethyl acetate, butyl acetate, dichloromethane, chloroform, methyl tert-butyl ether, diethyl ether, isopropyl ether, toluene, di 300mL each of 9 kinds of extractants such as toluene were extracted in 3 times, and the 10th group was the blank group. After the above 10 groups were extracted respectively, the aqueous phase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com