Apparatus and technology for producing integrally splicing hollow boards for building

A production method and hollow panel technology, applied in the field of integrally assembled building hollow panel production equipment, can solve the problems of poor weather resistance, penetration, unsuitability for load-bearing or external wall use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

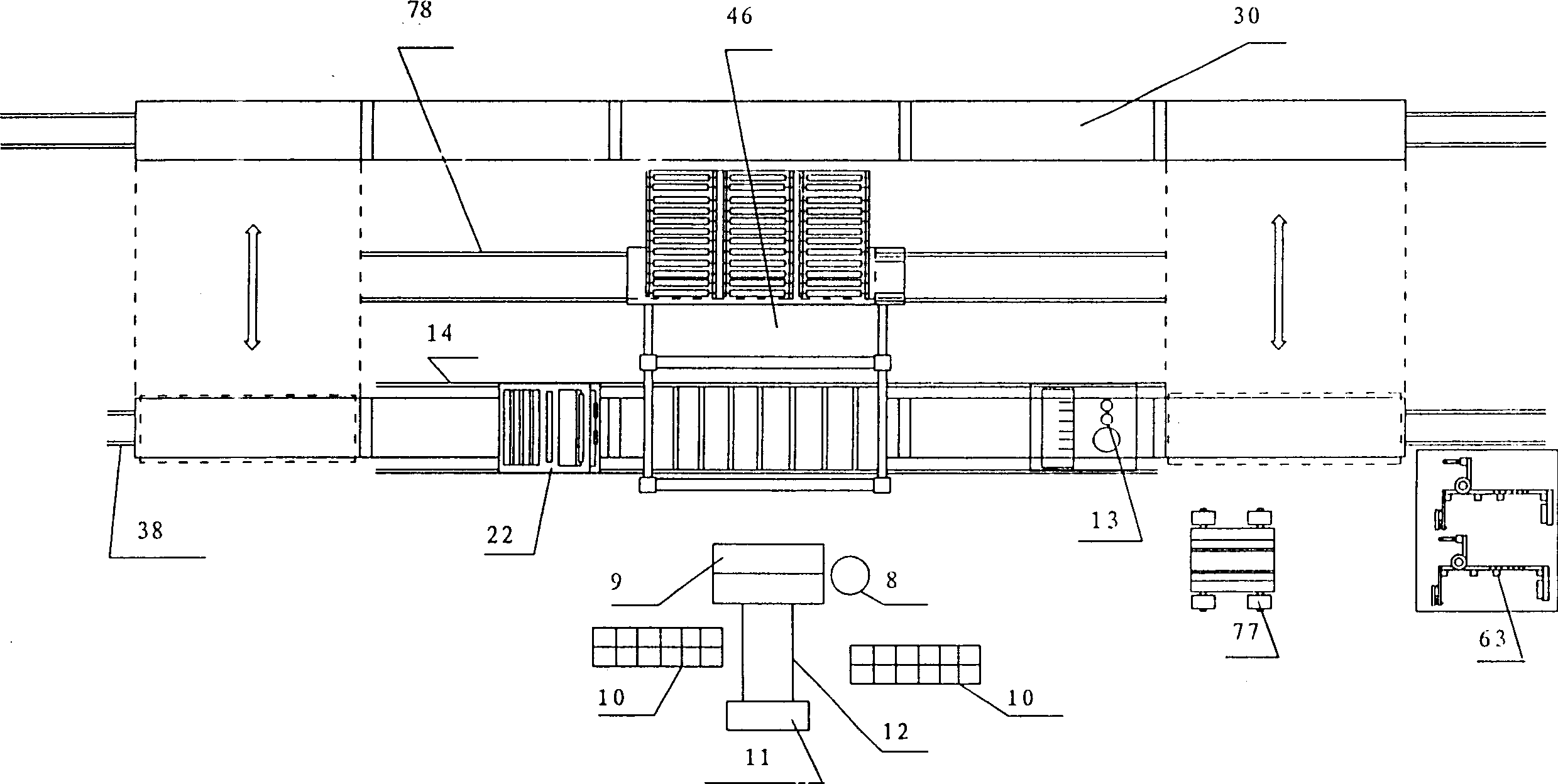

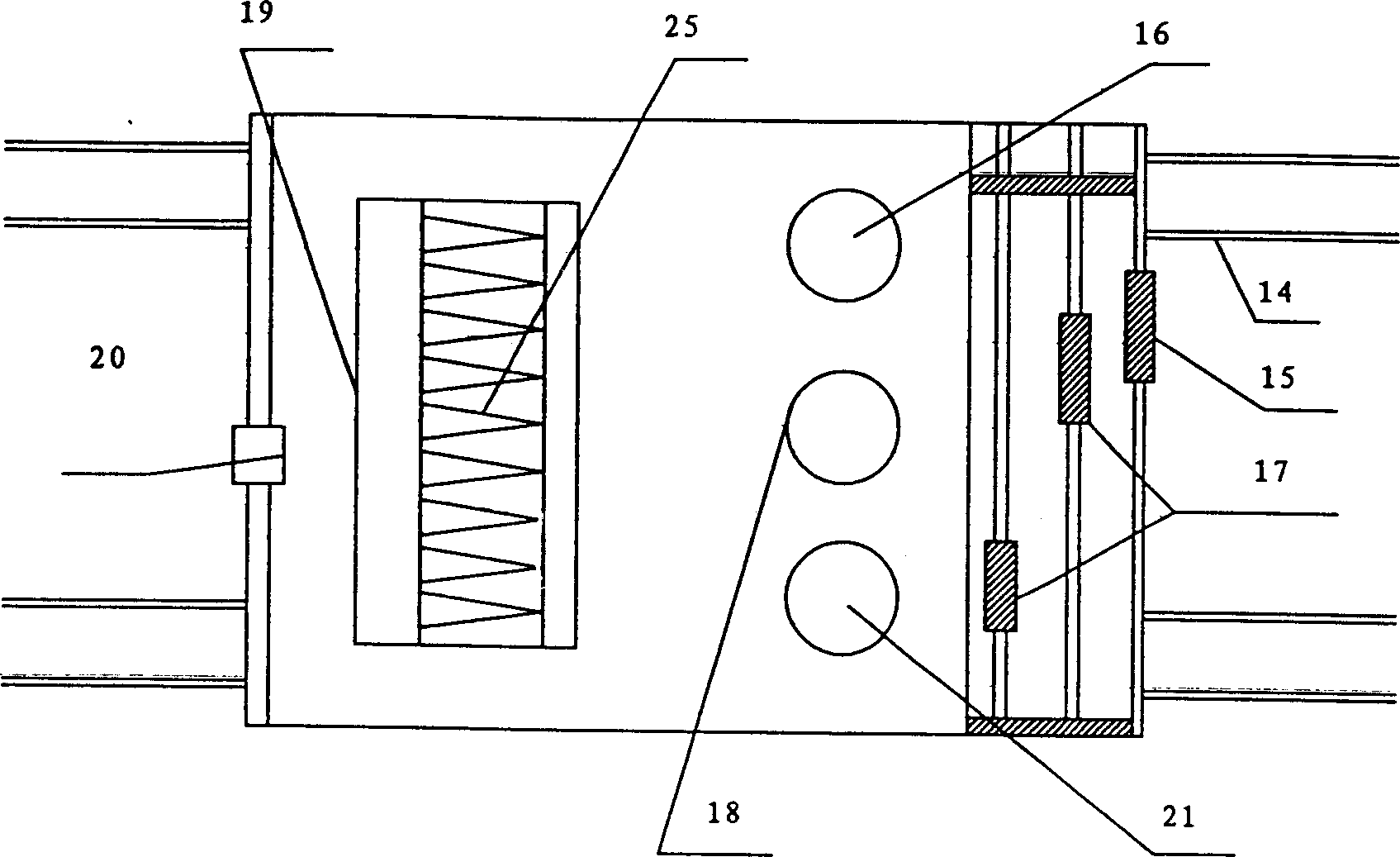

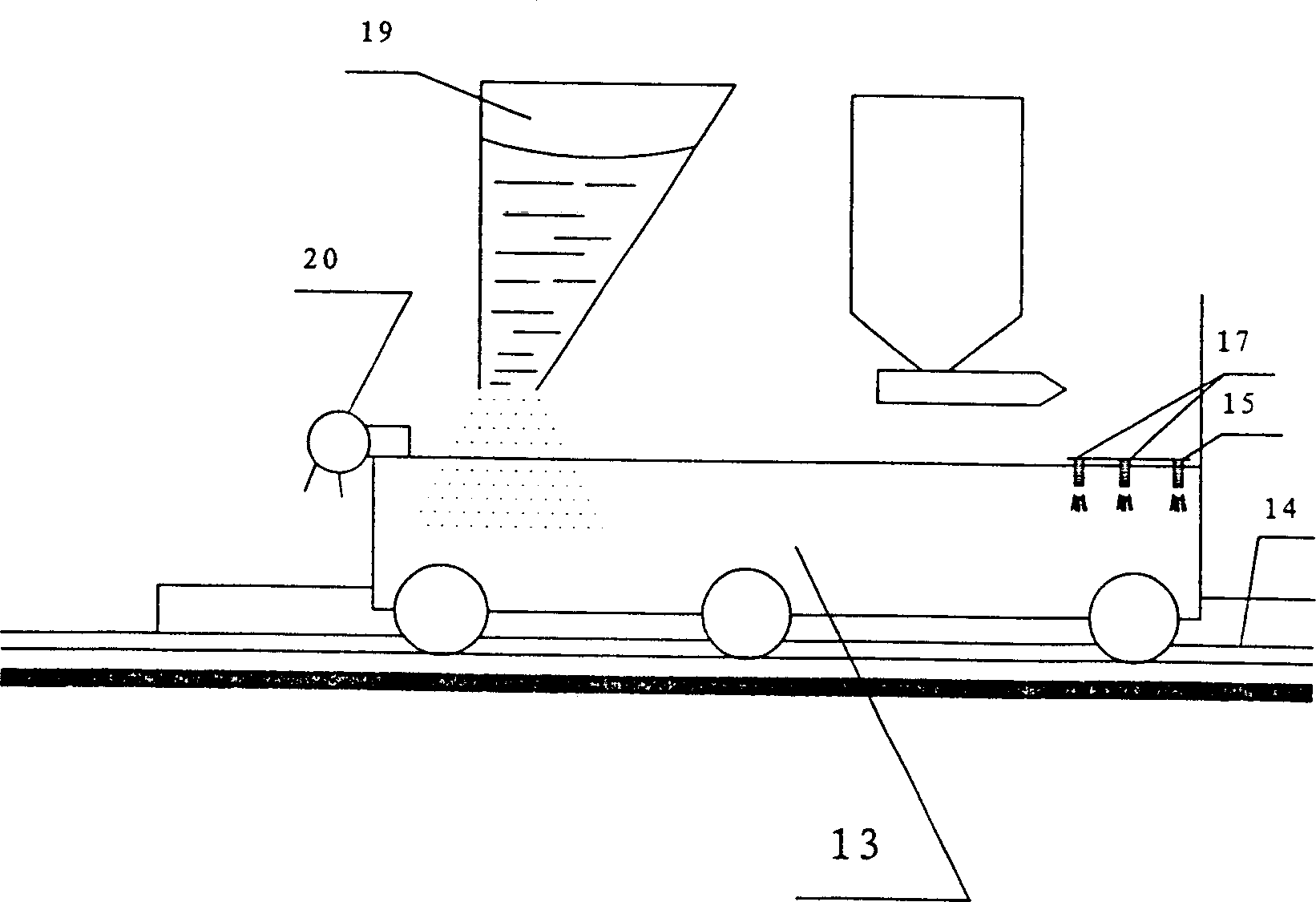

[0007] Refer to attached Figure 1-7 Integral assembled building hollow panel production equipment

[0008]The building hollow panel 1 includes opposite panels 2, back panels 3 and a plurality of spaced relative parallel and vertically connected reinforcing ribs 4 between panels 2 and back panels 3, thereby forming panels 2, back panels 3 and The cavity 6 between the reinforcing ribs 4, the decorative surface layer 7, the production equipment includes; 1, the combined slurry mixing station, which is used to mix various raw materials into a premixed slurry in proportion to supply the decorative layer combination The working vehicle and the combined working vehicle of the structural layer are used for spraying or distributing slurry; the combined slurry mixing station includes a decorative slurry mixer 8, a premix mixer 9, a raw material warehouse 10, a hopper 11, and a premix mixer 9. The hopper 11 can move back and forth along the feeding track 12; 2. The decorative layer com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com