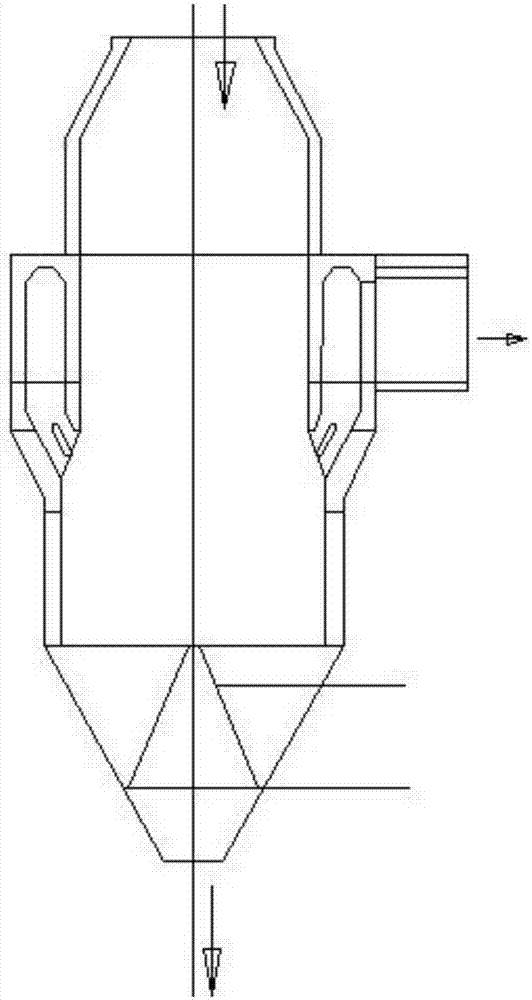

Refractory lining dual-chute of dry quenching furnace and technique method of building thereof

A technology of refractory inner lining and dry quenching coke oven, which is applied in coke oven bricklaying operations, coke oven, coke cooling, etc., which can solve the problems of failure to ensure smooth closing of combined bricks at joints, structural stability and precision. Guarantee, insufficient occlusal degree of the joint, etc., to achieve the effect of improving the working conditions in the furnace, uniform furnace gas direction, and simple implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

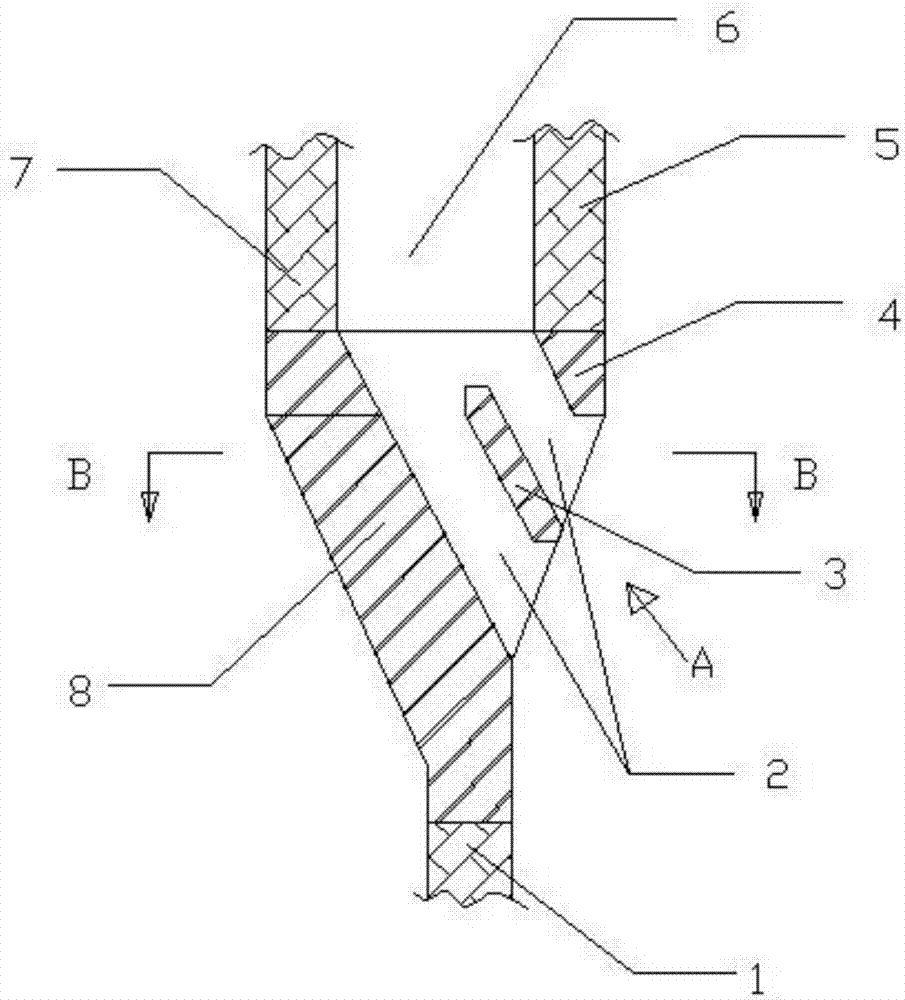

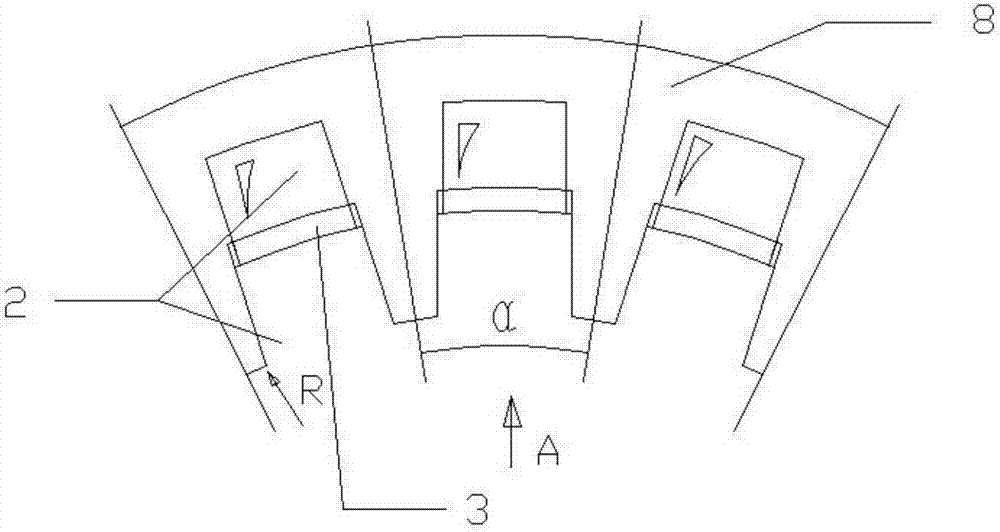

[0077] A process method for building refractory inner linings of CDQ coke ovens, comprising the following steps: Step 1: Select suitable refractory bricks according to the requirements of the equipment and perform a supporting preview; Step 2: Make standard jigs of corresponding sizes ; The third step: use tools to determine the position of each supporting wall; the fourth step, construct according to the corresponding datum line, during the masonry process, detect the error of the corresponding size in time and make adjustments.

Embodiment 2

[0079] A kind of process method of double-chute masonry for CDQ coke oven refractory lining in this embodiment is similar to Embodiment 1, the difference is that in the first step, the refractory brick is selected to be of a special type, and according to the supporting wall The arch support between the wall and the wall will be rehearsed at the manufacturer, packaged as a set after numbering, and then rehearsed on site, according to the steel structure and masonry installation errors, to correctly select reasonable refractory bricks.

Embodiment 3

[0081] A kind of process method of dry quenching coke oven refractory lining double chute masonry in this embodiment is similar to embodiment 1, the difference is that the standard jig made in the second step includes controlling the inner diameter of the supporting wall and spacing fixtures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com