Heat exchange pipe and on-line pipe-making processing technique thereof

A processing technology and technology of heat exchange tubes, applied in the field of metal tube processing, can solve problems such as heat exchange area, heat exchange efficiency is difficult to be greatly improved, cold processing technology is difficult to guarantee the quality of finished products, heat exchange tube finished specifications, length limitations, etc. , to achieve the effect of saving off-line heat treatment equipment, low cost of pipe making, and reduction of secondary processing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

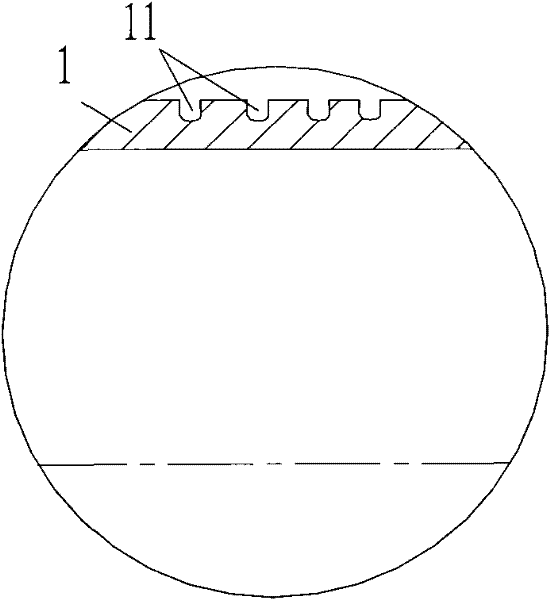

[0073] The heat exchange tube of the present invention is a metal tube with a certain length, mainly comprising a metal outer tube 1 and an inner tube 2 arranged inside the outer tube 1 , the two are closely matched and fixed together.

[0074] Such as Figure 5 As shown, in this embodiment, the outer pipe 1 is a metal welded pipe, such as austenitic stainless steel welded pipe, carbon steel welded pipe, titanium and titanium alloy welded pipe, nickel and nickel alloy welded pipe, or austenitic-ferrite dual phase steel welded pipe etc. The inner and outer surfaces of the outer tube 1 are both smooth surfaces.

[0075] The inside of the outer tube 1 forms a medium channel through which the heat exchange medium circulates, and an inner tube 2 is also provided. The inner tube 2 is used as a heat exchange component in the outer tube 1, and together with the outer tube 1 constitutes the heat exchange tube of the present invention. In this embodiment, the inner pipe 2 is also a m...

Embodiment 2

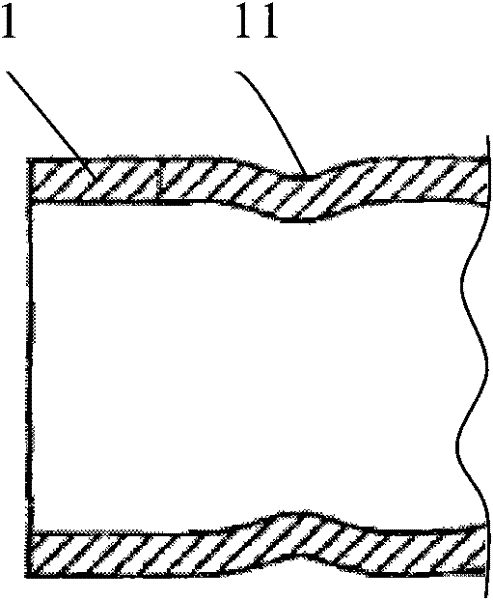

[0094] Such as Figure 6 As shown, the structure of the heat exchange tube of this embodiment is basically the same as that of the above-mentioned embodiments, and both include an outer tube 1 and an inner tube 2 used as a heat exchange component. The difference is that the outer surface of the inner tube 2 is spiral.

[0095] In other embodiments, T-shaped grooves, screw grooves, etc. are provided on the outer surface of the inner tube 2 to achieve basically the same technical effect.

Embodiment 3

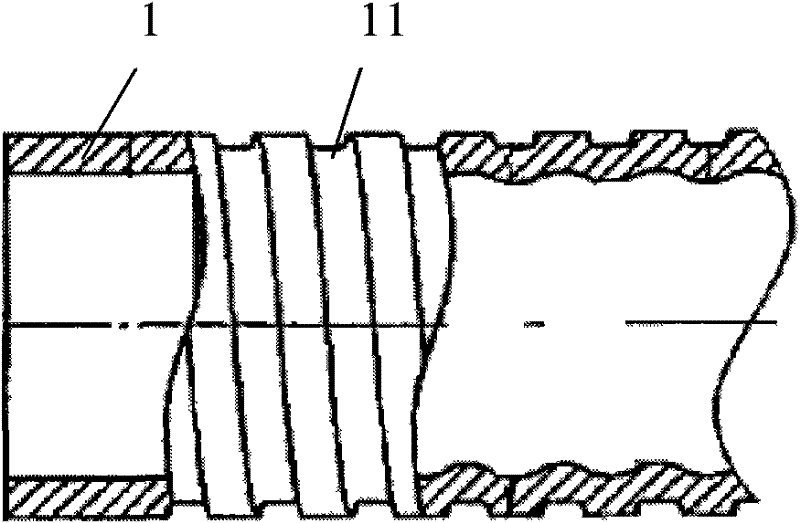

[0097] The structure of this embodiment is basically the same as that of Embodiment 1, including an outer tube 1 and an inner tube 2. The difference is that the cross-sectional shape of the inner tube 2 is triangular, and three direct heat exchange zones 31 are formed in the outer tube 1. and an indirect heat exchange zone 32.

[0098] In addition, at least one through hole 23 is provided on the tube wall of the inner tube 2 . These through holes 23 may be O-shaped holes or star-shaped holes or polygonal holes or other special-shaped holes.

[0099] Preferably, see Figure 7 , Figure 8 Shown is the side view structure of the inner tube 2 in this embodiment, and a plurality of through holes 23 are distributed in an array on the tube wall of the inner tube 2 .

[0100] In other embodiments, the cross section of the inner tube 2 can have various forms. Such as Figure 9A , Figure 9B , Figure 9C , Figure 9D , Figure 9E , Figure 9F , Figure 9G , Figure 9H , Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com