LED material strap with identification structure

A material tape and lead frame technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of mold cost, process time-consuming, product cost increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the attached drawings are only for reference and illustration, and are not used to limit the present invention.

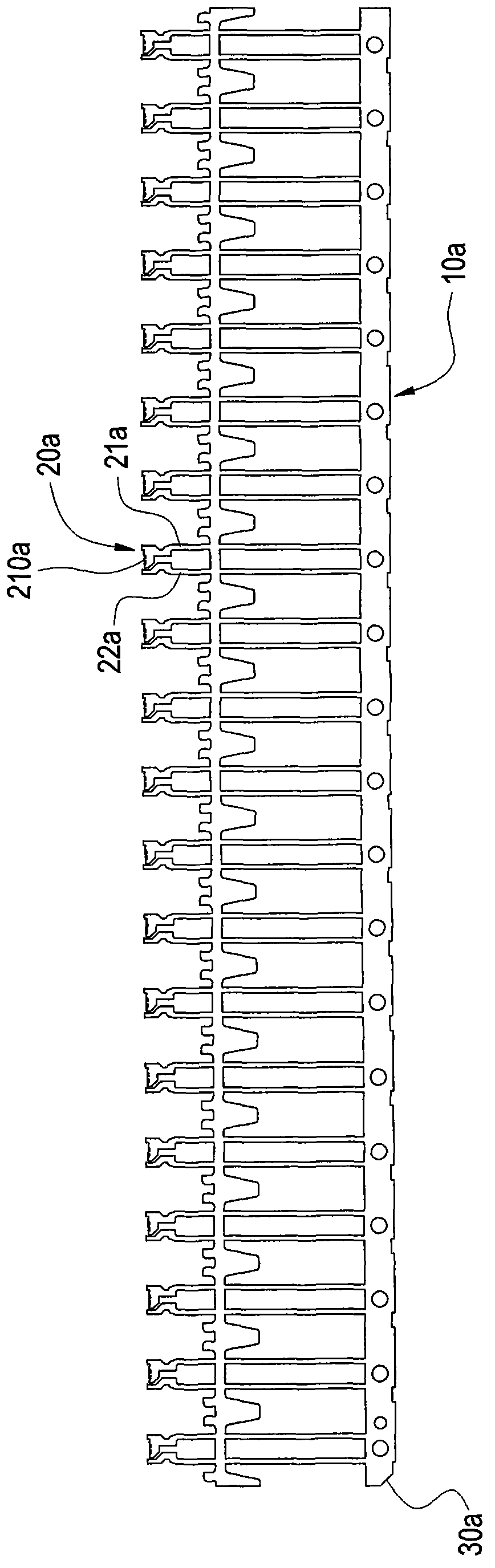

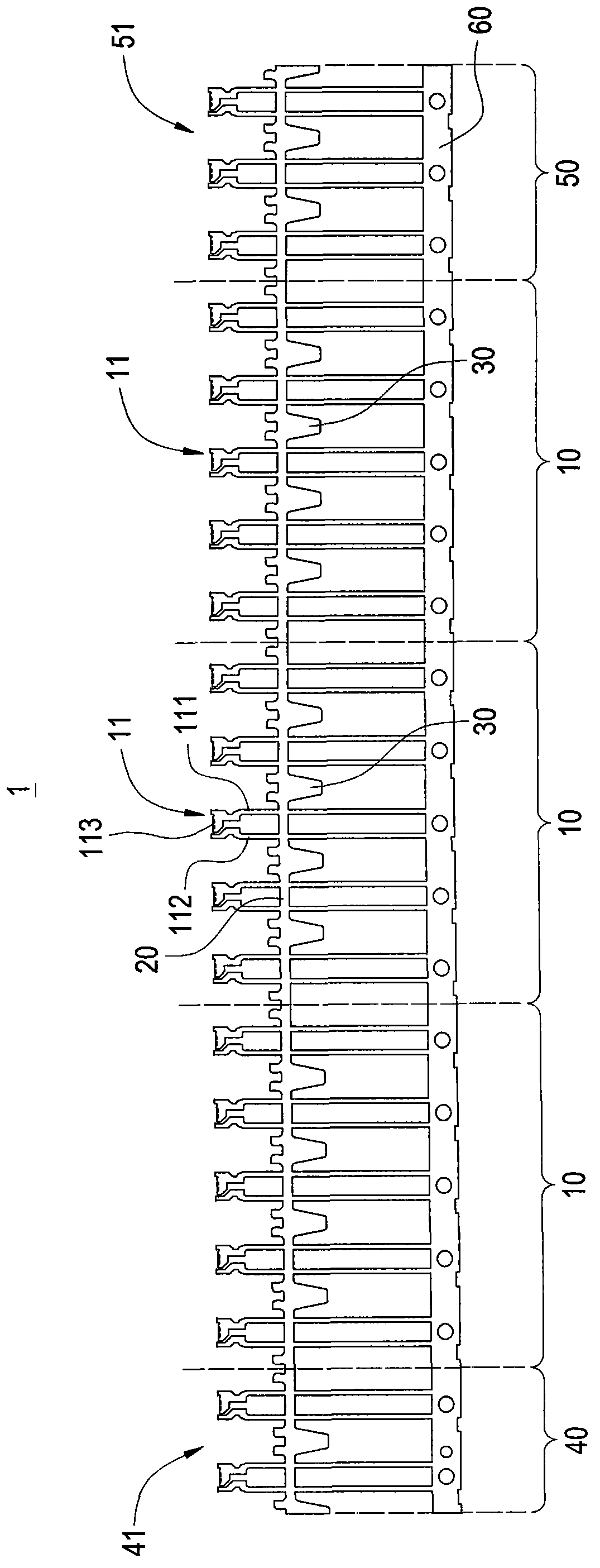

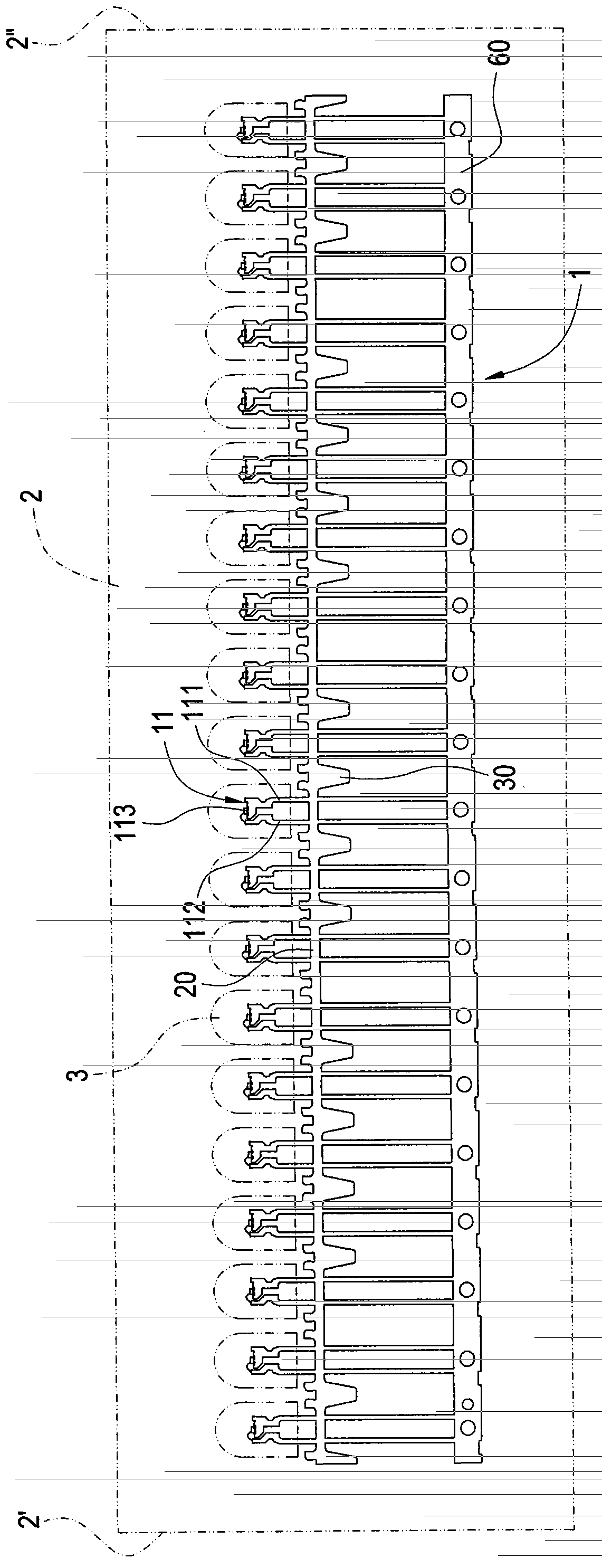

[0034] Please refer to figure 2 , is a schematic plan view of the LED strip with identification structure of the present invention, the LED strip 1 includes a plurality of lead frame groups 10, at least one main connecting section 20, a plurality of clamping pieces 30, and a first zero-distortion lead frame 40 And the second zero-distortion lead frame 50.

[0035] These lead frame groups 10 are arranged in a straight line, and each lead frame group 10 includes a certain number of bracket units 11; It then includes five bracket units 11 . Each of the bracket units 11 includes a first pin 111 and a second pin 112 arranged at intervals. The first pin 111 is formed with a concave cup 113 for a LED chip.

[0036] The main connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com