Formation method of straw solidifying and blow-filling sludge pile

A technology of dredging silt and straw filling, which is applied in the forming field of silt piles. It can solve the problems of reducing the bearing capacity of the foundation, the straw cannot be pulled out, and the straw is loose, so as to improve the bearing capacity of the foundation, shorten the curing and molding time, and reduce the decay speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

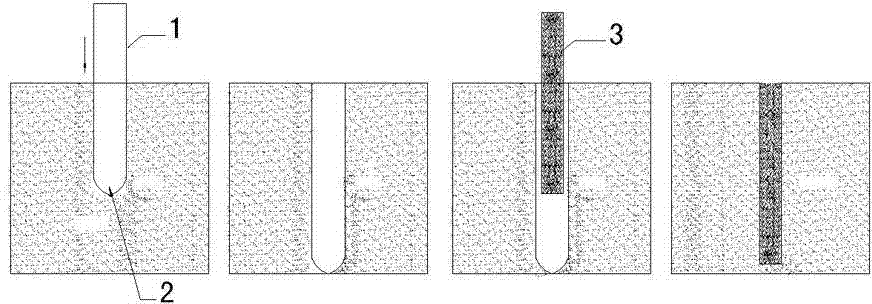

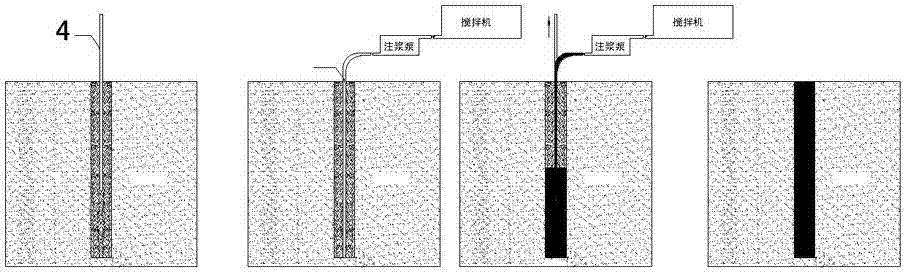

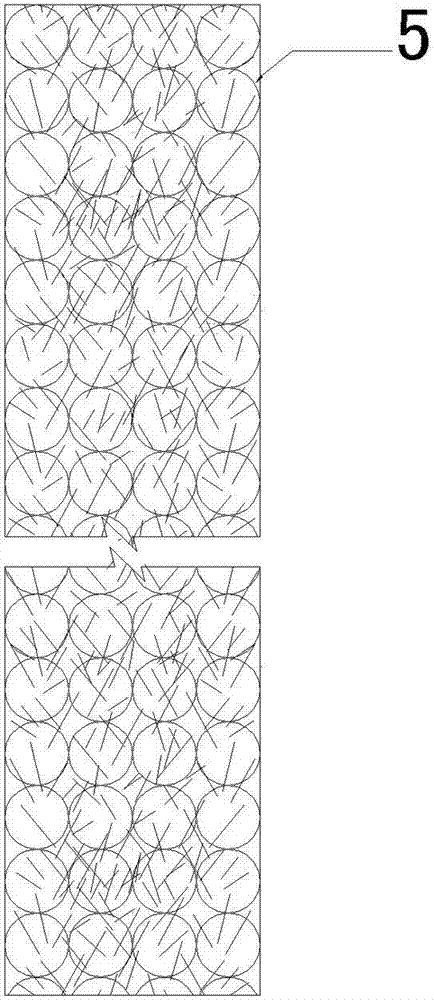

[0033] A kind of forming method of straw solidified dredging mud pile of the present embodiment, such as figure 1 As shown in ~4, perform the following steps:

[0034] 1) Put the hollow metal tube 1 with the bottom cover 2 vertically into the mud, the bottom cover 2 can be separated from the hollow metal tube 1, and fill the straw into the hollow metal tube 1, and then put the hollow metal tube The pipe 1 is pulled out from the silt, so that the stalks form a vertically arranged straw drainage body 3 in the silt;

[0035] 2) Set horizontal drainage body on the silt surface;

[0036] 3) Lay a layer of sealing film on the surface of the sludge, and use a vacuum device to perform vacuum preloading and consolidation treatment on the sludge;

[0037] 4) Insert the hollow metal grouting pipe 4 into the straw drainage body 3, pump the solidified material stirring slurry into the hollow metal grouting pipe 4 until the solidified material stirring slurry overflows the straw pile, sto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Mesh aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com