Transparent bloomless silicone rubber mixed compound and preparation method

A technology of rubber compound and silicone rubber, which is applied in the extrusion production of products and the production process of extruded silicone rubber compound, which can solve the problems of opacity of silicone rubber products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0018] Silicone rubber compound 95-100 parts, DCBP 1.0-1.5 parts.

[0019] Preferably, 100 parts of silicone rubber compound; 1.0 part of DCBP.

[0020] making process:

[0021] Disperse and mix 100 parts of silicone rubber and 1.0 part of DCBP on a two-roll mixer.

[0022] Physical and mechanical performance sample preparation, take 500 grams of uniformly mixed rubber, put it into a mold, and vulcanize it on a flat vulcanizing machine to prepare a standard sample for testing physical and mechanical properties. Vulcanization conditions for sample preparation: the vulcanization pressure is 8MP, the vulcanization temperature is 160°C, and the vulcanization time is 8min.

[0023] The appearance of the frosting observation sample is prepared. Take 5000 grams of uniformly mixed rubber material, extrude it through a rubber extruder and a 10mm diameter round rod mold, and set the vulcanization temperature at 500°C for 10s; , the time is 5min, and a transparent round glue stick wit...

specific Embodiment 2

[0034] The silicone rubber compound includes 100 parts of methyl vinyl silicone rubber, 0.5 parts of DCBP, and 0.8 parts of alkoxy peroxide.

[0035] making process:

[0036] Disperse and mix 100 parts of silicone rubber, 0.5 part of DCBP and 0.8 part of alkoxy peroxide on a two-roll mixer.

[0037] Physical and mechanical performance sample preparation, take 500 grams of uniformly mixed rubber, put it into a mold, and vulcanize it on a flat vulcanizing machine to prepare a standard sample for testing physical and mechanical properties. Vulcanization conditions for sample preparation: the vulcanization pressure is 8MP, the vulcanization temperature is 160°C, and the vulcanization time is 8min.

[0038] The appearance of the frosting observation sample is prepared. Take 5000 grams of uniformly mixed rubber material, extrude it through a rubber extruder and a 10mm diameter round rod mold, and set the vulcanization temperature at 500°C for 10s; , the time is 5min, and a transpa...

specific Embodiment 3

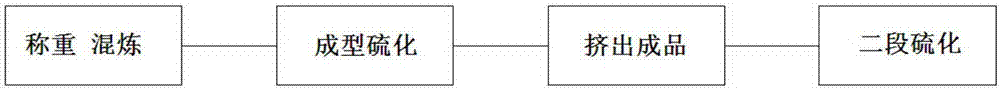

[0048] Using the transparent frost-free silicone rubber compound of the present invention, a sealing strip for a sterilizing cabinet is prepared and put into the market for customers to use. The manufacturing process is:

[0049] Mixing: Weigh 10 kg of methyl vinyl silicone rubber compound, knead it on a double-roller mixer until it covers the rolls, add 30 grams of DCBP and 80 grams of alkoxy peroxide BPMC in batches, mix evenly, and release the sheet (about 10mm thick and about 400mm wide).

[0050] Extrusion molding: Cut the film into strips with a width of about 50 mm, extrude and shape the rubber extruder and a mold with inner diameter*diameter=8*20 mm, the curing temperature is 500 ° C, and the time is 10 seconds; the rubber hose after shaping Vulcanize through a horizontal drying tunnel, the temperature of the horizontal drying tunnel is 260°C, and the time is 5 minutes.

[0051] Two-stage vulcanization: Put the extruded rubber hose into a two-stage oven, keep it warm f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com