Printed fabric surface defect detection method based on image processing

A defect detection and image processing technology, applied in image data processing, image enhancement, image analysis, etc., can solve problems such as low accuracy, inconsistent detection standards, etc., to improve production efficiency, reduce waste, and reduce secondary processing. effect of probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

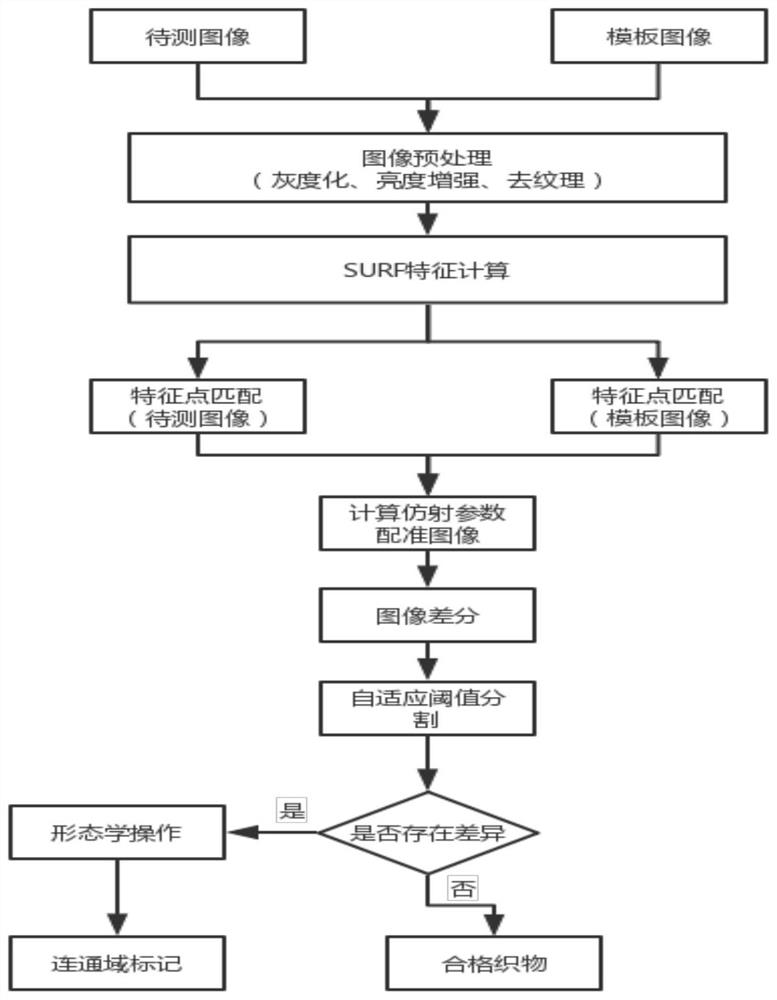

[0039] A method for detecting surface defects of printed fabrics based on image processing of the present invention is specifically implemented according to the following steps:

[0040] Step 1, collecting the template image and collecting the cloth image to be detected;

[0041] Step 2, perform the same preprocessing on the template image and the cloth image to be detected, including grayscale, brightness adjustment, image blurring, and detexturing;

[0042] The grayscale is specifically:

[0043] (1) calculate template image and the component of each pixel point RGB of cloth image to be detected by OpenCV function;

[0044] (2) Calculate the weighted gray value: 0.3×B+0.59×G+0.11×R;

[0045] (3) Assign the weighted gray value calculated in (2) to each corresponding pixel in (1);

[0046] The expression for adjusting brightness is:

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com