Printing technology for pure cotton or polyester-cotton jean

A denim and polyester-cotton technology, applied in the field of textile printing and dyeing, can solve the problems of complex process, large water consumption and sewage discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

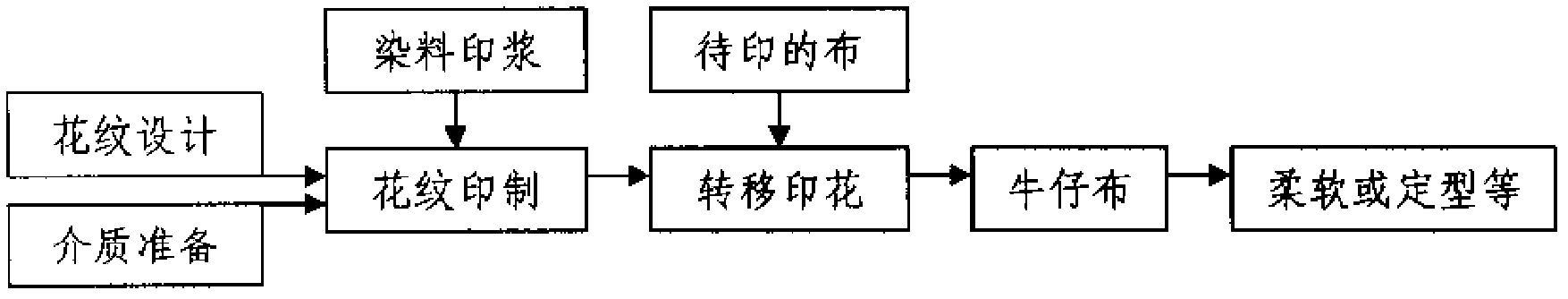

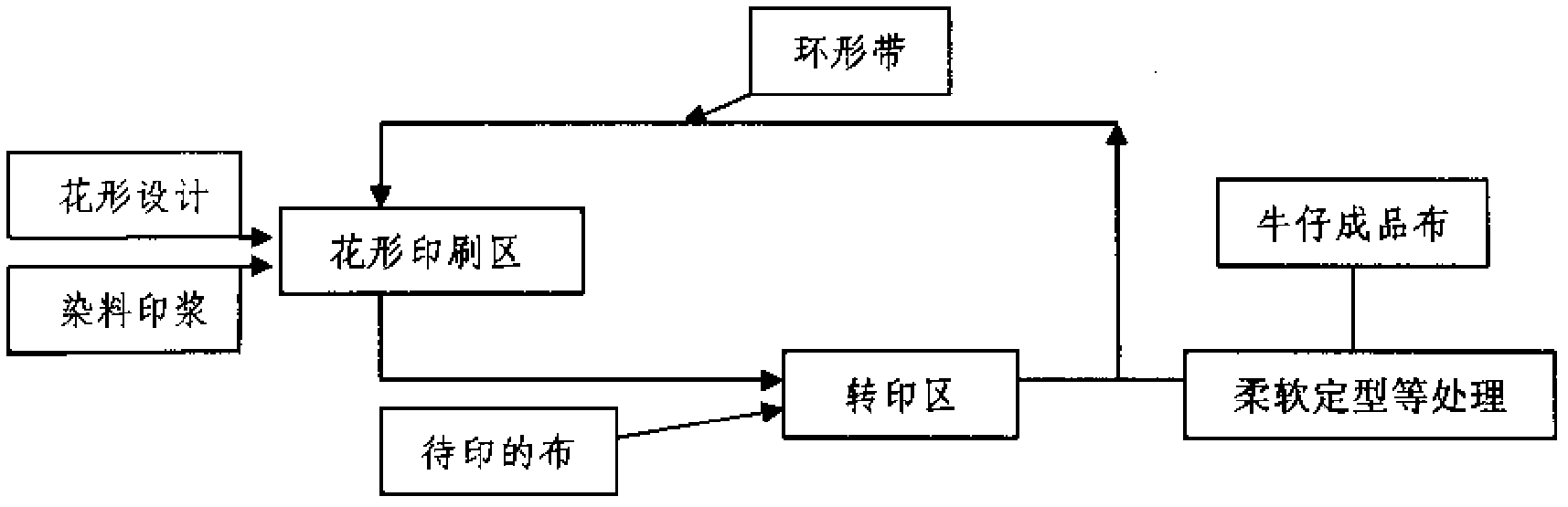

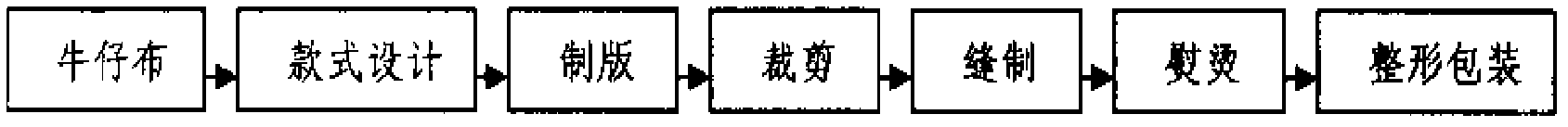

Method used

Image

Examples

Embodiment 1

[0034] 1) The dyestuff is made into water-based ink: get 25wt% polyacrylate as binder, dispersant 1wt% fatty alcohol polyoxyethylene ether, 40wt% reactive yellow 86, 0.02wt% benzoic acid, 0.05wt% poly Sodium acrylate and 0.5wt% industrial alcohol are mixed, and the rest is water to make water-based ink LY-86;

[0035] 2. Use bridging agent to pretreat the pure cotton cloth by padding and shaping and drying at a temperature of 50°C to make the cloth to be printed;

[0036] 3) Print the designed denim pattern on the paper by printing;

[0037] 4) The paper that has been printed with the pattern is attached to the above-mentioned cloth to be printed, and passes through the transfer area of the cold transfer machine synchronously. In the transfer area, the pattern on the paper is transferred to the cloth to complete the denim. Printed, then cold-stacked and washed. Transfer printing at room temperature, cold stacking at room temperature.

[0038] 5) Soften and shape the print...

Embodiment 2

[0040] 1) Dye is made into water-based ink: get 30wt% carboxymethyl cellulose as binder, 1wt% lignin, 20wt% disperse blue 56, 0.05wt% sorbic acid, 0.1wt% oxidized starch and 0.2wt% % n-butyl ester is mixed, and the rest is water to make water-based ink TB-56;

[0041] 2. Use bridging agent to pretreat pure cotton cloth by padding and shaping and drying at room temperature to make cloth to be printed;

[0042] 3) Print the designed denim pattern on the paper by printing;

[0043] 4) The paper that has been printed with the pattern is attached to the above-mentioned cloth to be printed, and passes through the transfer area of the heat transfer machine synchronously. In the transfer area, the pattern on the paper is transferred to the cloth to complete the denim. print. 190°C transfer printing, speed 30m / min.

[0044] 5) Soften and shape the printed denim according to conventional conditions.

Embodiment 3

[0046]1) Dye is made into water-based ink: get 50wt% water glass as binder, 1wt% bentonite, 30wt% Disperse Red 60, 0.05wt% paraben, 0.1wt% oxidized hydroxypropyl starch and 0.2 Wt% propylene oxide is mixed, and the rest is water to make water-based ink TR-60;

[0047] 2. Use bridging agent to pretreat pure cotton cloth by padding and shaping and drying at room temperature to make cloth to be printed;

[0048] 3) Print the designed denim pattern on the paper by printing;

[0049] 4) The paper that has been printed with the pattern is attached to the above-mentioned cloth to be printed, and passes through the transfer area of the heat transfer machine synchronously. In the transfer area, the pattern on the paper is transferred to the cloth to complete the denim. print. 180°C transfer printing, speed 30m / min.

[0050] 5) Soften and shape the printed denim according to conventional conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com