Method for producing tetramethylthiuram disulfide (TMTD) by methanol method

A methanol method and methanol technology, applied in the field of methanol production of TMTD, can solve the problems of poor product quality, environmental pollution, short shelf life, etc., and achieve the effects of low cost, no raw material loss, and long shelf life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] In a pressure reactor (autoclave), put 150 kg of methanol, 550 kg of dimethylamine aqueous solution with a mass concentration of 40% and 350 kg of carbon disulfide, and oxygen at room temperature to a gauge pressure of 0.08Mpa, and react at 25-28℃6 Hours; cooling to below 26℃, discharge the materials in the reaction kettle, suction filtration or centrifugation, the solid is vibrated and dried at 80℃, and discharged in about 60 seconds to obtain a white or off-white product with a yield of 92-96% and a purity of 98.5% Above, the melting point is 142-145.7; the filtrate is distilled to separate methanol for recycling in the next production.

Embodiment 2

[0020] In a pressure reactor (autoclave), put 300 kg of methanol, 1100 kg of dimethylamine aqueous solution with a mass concentration of 40% and 700 kg of carbon disulfide, and oxygen at 50°C to a gauge pressure of 0.1Mpa, and react at 25-28°C 6 hours; cooling to below 26℃, discharge the materials in the reactor, suction filtration or centrifugation, shake and dry the solid at 80℃, discharge in about 60 seconds, obtain a white or off-white product, yield 92-96%, purity 98.5 % Above, the melting point is 142-145.7; the filtrate is distilled to separate methanol for recycling in the next production.

Embodiment 3

[0022] In a pressure reactor (autoclave), put 150 kg of methanol, 500 kg of dimethylamine aqueous solution with a mass concentration of 40% and 300 kg of carbon disulfide, and oxygen at 50°C to a gauge pressure of 0.2Mpa, and react at 25-28°C 5 hours; cooling to below 26℃, discharge the materials in the reaction kettle, suction filtration or centrifugation, the solid is vibrated and dried at 80℃, and discharged in about 60 seconds, a white or off-white product is obtained, the yield is 92-96%, the purity is 98.5 % Above, the melting point is 142-145.7; the filtrate is distilled to separate methanol for recycling in the next production.

[0023] Benefits:

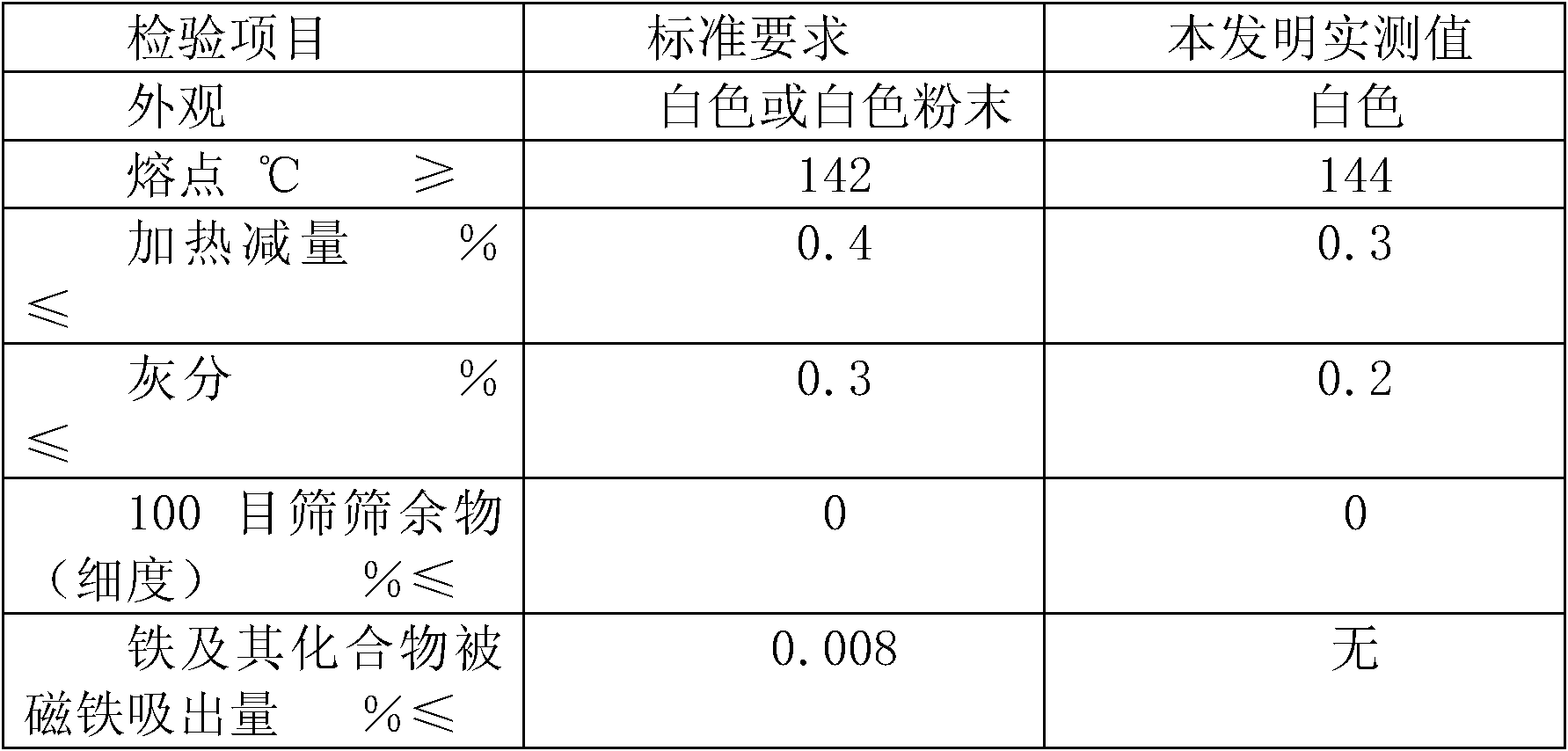

[0024] The product produced by the present invention meets the national inspection standards, and the indicators of the product in Example 1 are

[0025]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com