Ceramic tile preparation method and product thereof

A technology for ceramic tiles and a manufacturing method, applied in the field of ceramic manufacturing, can solve the problems of unnatural decorative effect, increased labor cost, color difference and texture difference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

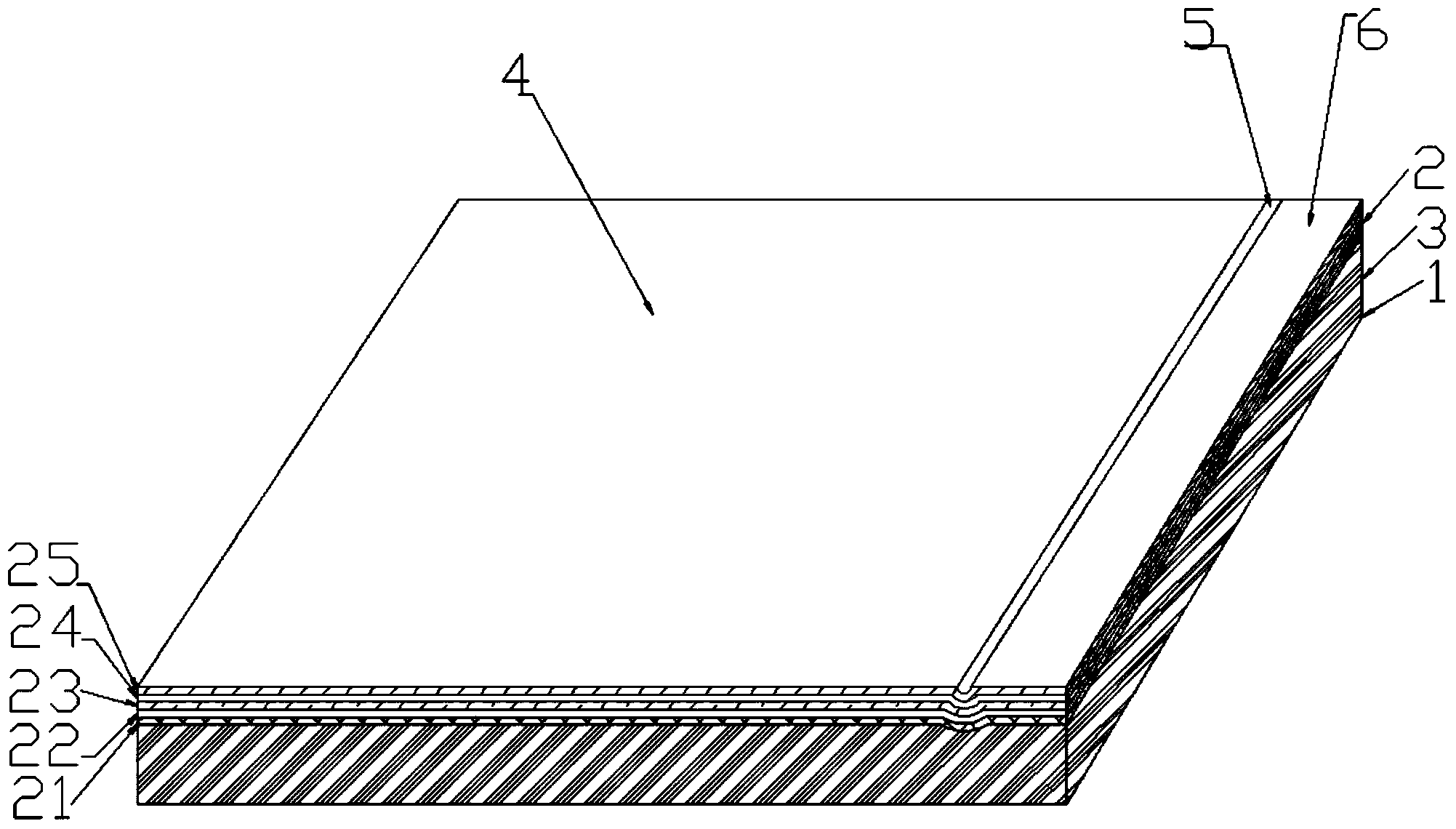

[0034] Such as figure 1 As shown, a ceramic tile 1 of the present embodiment comprises a decorative layer 2 and a green body layer 3 from top to bottom, and the decorative layer 2 is provided with an arc-shaped groove 5, and the arc-shaped groove 5 will The ceramic tile 1 is divided into a main brick part 4 and a waistline part 6; the depth of the arc-shaped groove 5 is 0.5 mm; the width of the arc-shaped groove 5 is 3 mm; the decorative layer 2 is a multi-layer structure, which sequentially includes a bottom glaze layer 21, an inkjet decoration layer 22, a printing decoration layer 23, a transparent glaze layer 24, and a decoration glaze layer 25 from bottom to top.

[0035] As mentioned above ceramic tile preparation method, the steps are as follows:

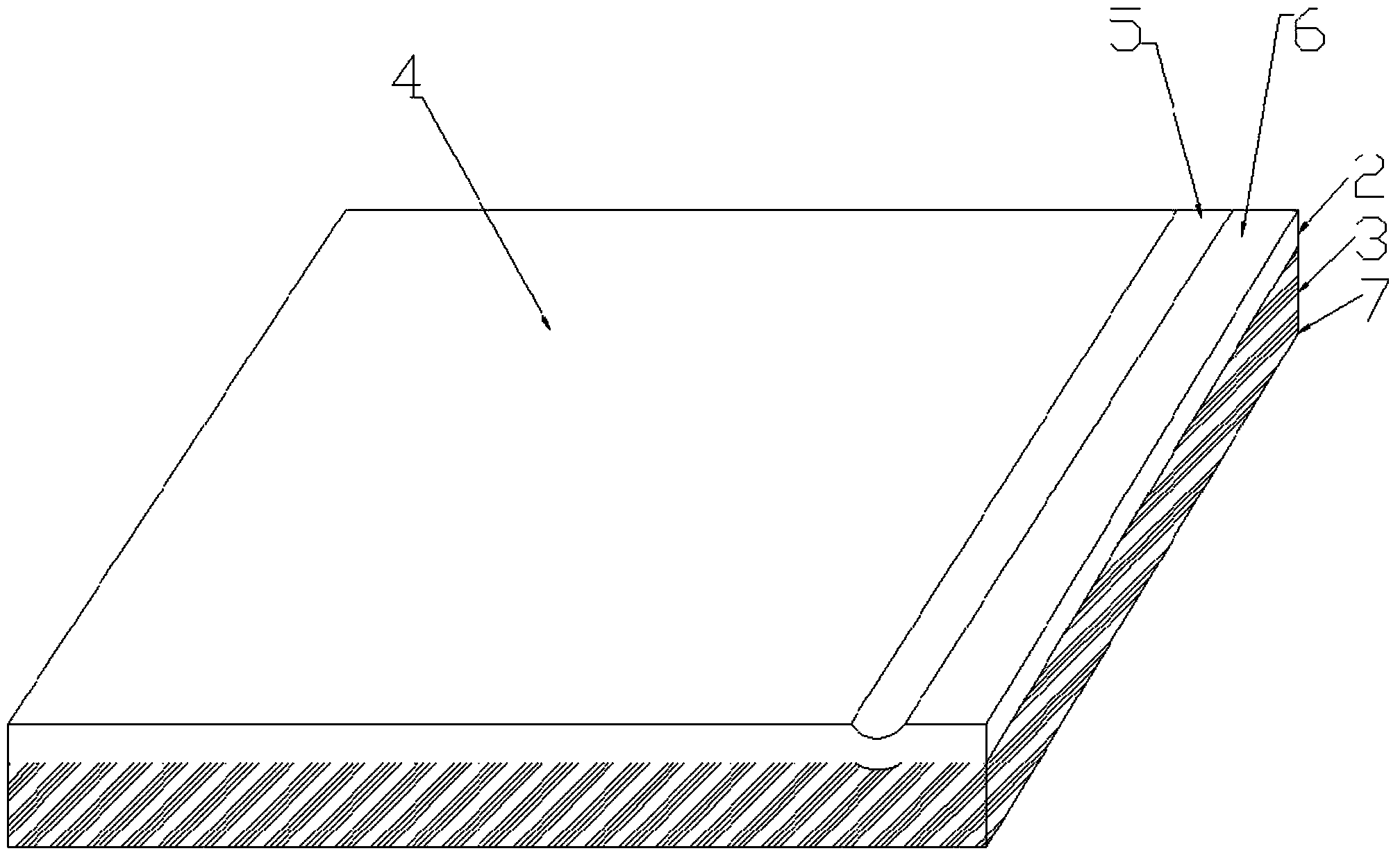

[0036] A: Mold design: Design and manufacture the molds for the ceramic tile products, such as figure 2 As shown, the mold 7 includes a main brick part 4, an arc-shaped groove 5, and a waistline part 6, and the arc-shaped g...

Embodiment 2

[0047] The difference between this embodiment and Embodiment 1 is that the step D of manufacturing the ceramic tiles of this embodiment is to use screen printing to form a printed decorative layer 23, and the step F is the technology of using dry cloth glaze A decorative glaze layer 25 is formed, and the printed decorative layer 23 and the decorative glaze layer 25 are both partially decorated.

Embodiment 3

[0049] The step F of this embodiment is to form the decorative glaze layer by combining the metal glaze, the cracked glaze and the kiln-changed glaze at random, and the glaze formula of the transparent glaze in the step E is as follows: Glaze powder 80%, transparent frit 12%, kaolin 8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com