Cosolidation with sludge dredging and water draining

A technology for drainage, consolidation and dredging of silt, which is used in water filling, infrastructure engineering, construction, etc., can solve the problems of long consolidation time and low silt permeability coefficient, and achieve sustainable development and save engineering. Cost, the effect of eliminating the need for secondary processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

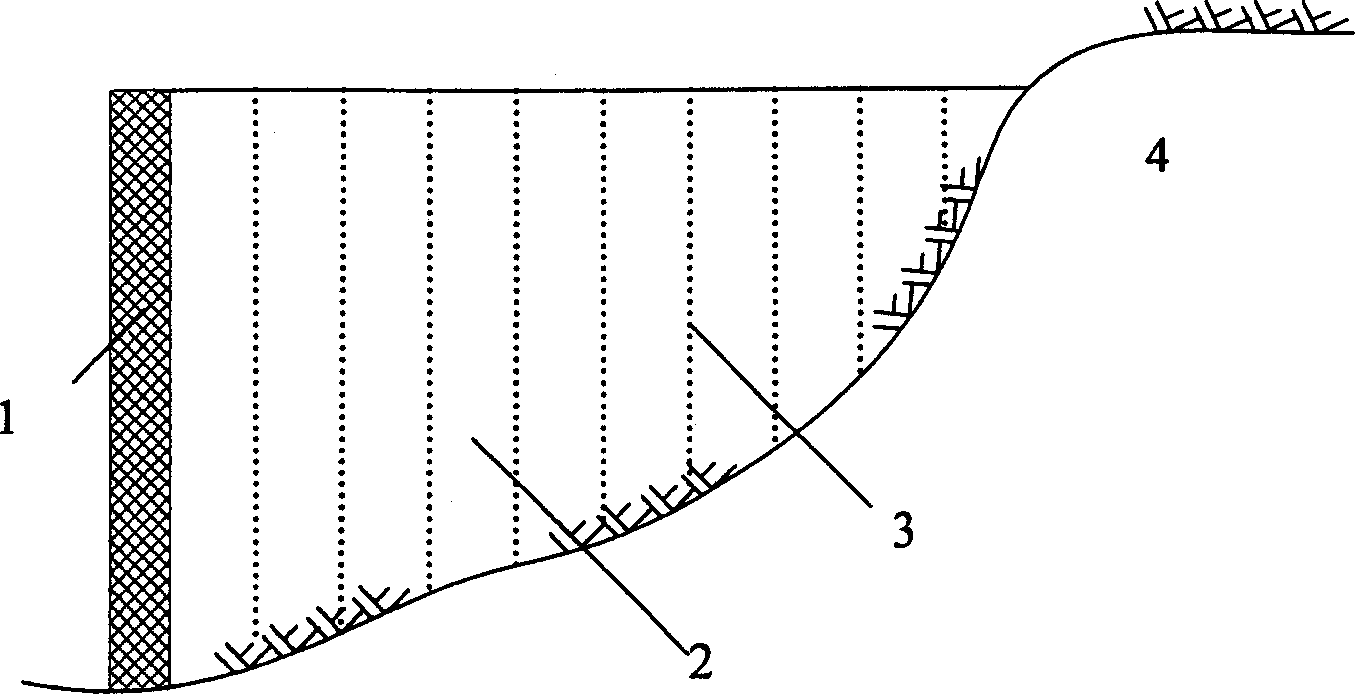

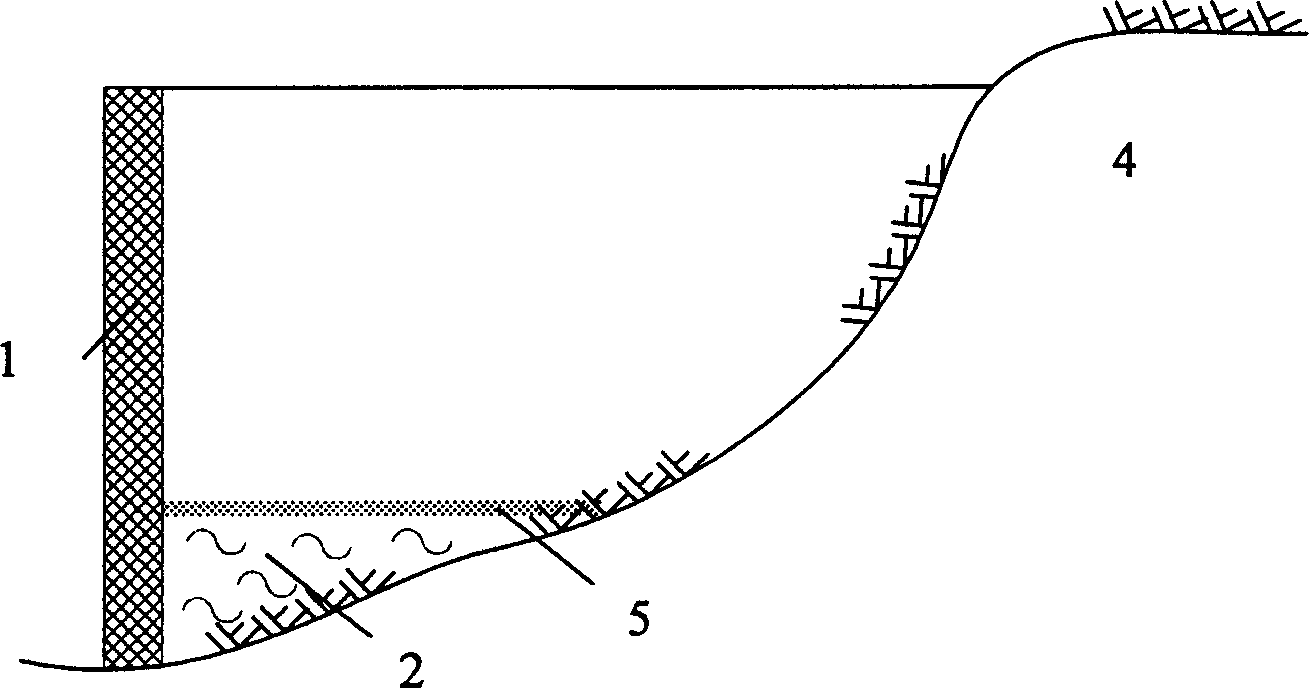

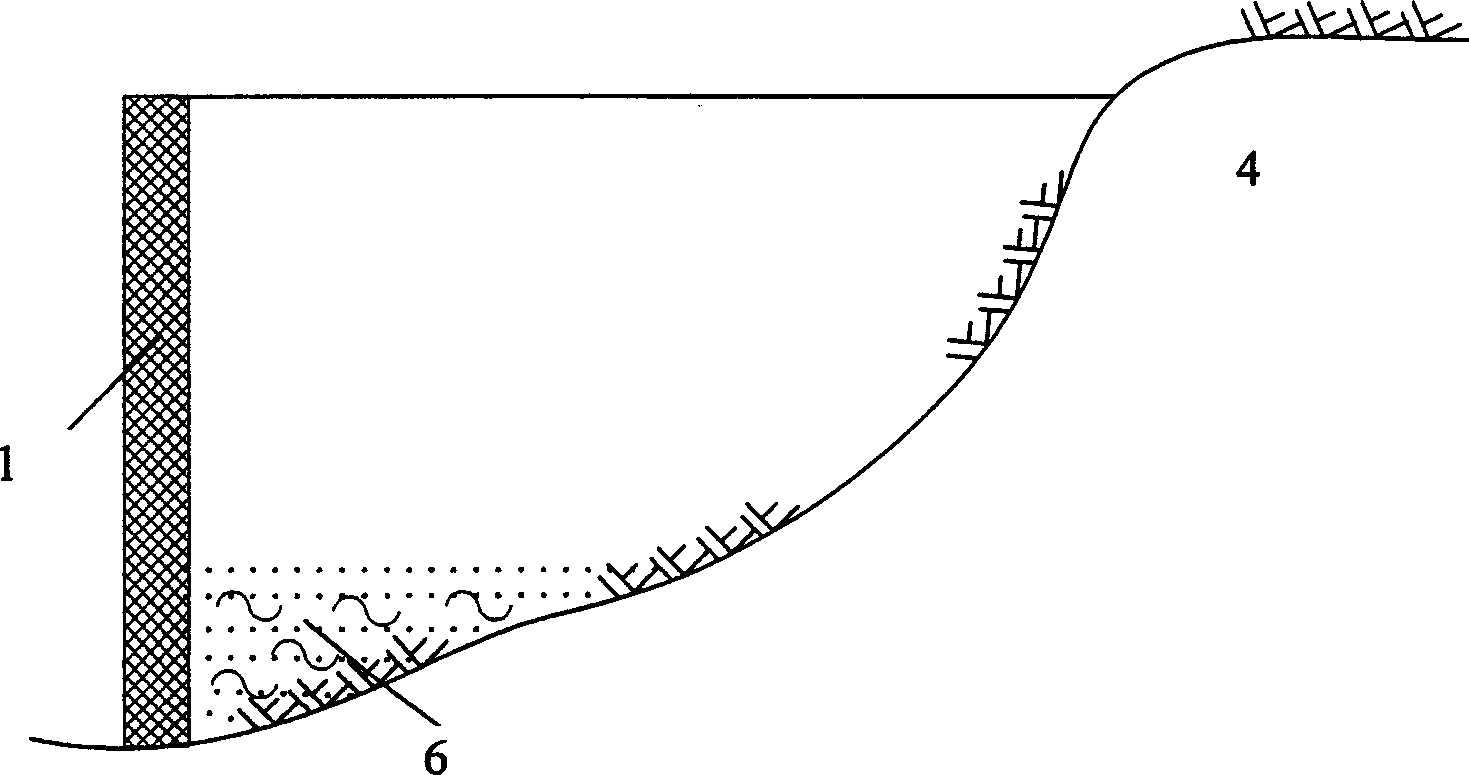

[0029] There is a large amount of marine silt in the harbor basin in front of a caisson-type wharf in a port that needs to be dredged, and a large amount of backfilling is required in the rear freight yard area for land reclamation. Therefore, the dredging and consolidation method of silt drainage is used for land reclamation. The silt is sucked out of the pool and then transported to the rear freight yard area through the pipeline. This method is used for treatment. The expected strength of the cross plate of the soil after filling is 30kPa. The specific operation steps are as follows:

[0030] 1) In the rear area, use riprap to form a cofferdam with a thickness of 0.5m;

[0031] 2) Fill a layer of silt into the cofferdam with a thickness of 1.5m, and then fill a layer of 0.4m sand layer on the top of the silt, and the sand layer will sink into the silt under its own weight to form a silt-sand mixture.

[0032] 3) Repeat step 2) until the design elevation;

[0033] 4) After...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com