Hole processing method for which low-melting-point alloy sacrificial layer is adopted

A hole processing method and low melting point technology, applied in the field of electrolytic machining, can solve the problems of out-of-tolerance hole diameter, scrapped parts, affecting the consistency of hole diameter at the exit of a group of holes, etc., to improve versatility, avoid secondary corrosion, and improve processing stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

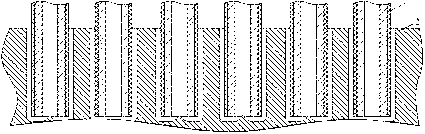

[0032] figure 1 In the process, the thickness of the part is not uniform, and the group holes appear successively through;

[0033] figure 2 In the process, the group of holes appear to penetrate successively, and the holes that penetrate first will undergo secondary corrosion, forming trumpet-shaped small holes;

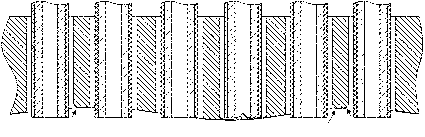

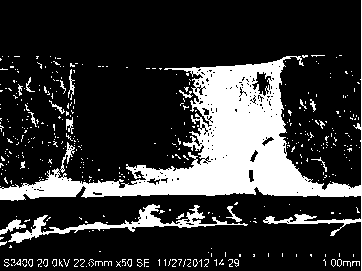

[0034] Figure 4 In the process, the low-melting point alloy is coated on the exit position of the predetermined machining hole of the part;

[0035] Figure 5 In, after coating the low melting point alloy, the current is redistributed and the secondary corrosion is avoided.

[0036] to combine Figure 4 , 5 , 6, illustrate the implementation process of the present invention:

[0037] (1). Use the method of spraying to evenly coat the molten low-melting point alloy at the exit position of the predetermined machining hole of the workpiece, and cool it in the air;

[0038] (2). Electrolytic processing of tube electrodes;

[0039] (3). After processing, heat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com