Ultrahigh performance sea sand concrete and preparation method thereof

An ultra-high-performance concrete technology, applied in the field of new building materials, can solve the problems that limit the application of ultra-high-performance concrete on-site pouring, and achieve the effect of promoting development and application and low overall cost

Inactive Publication Date: 2018-01-12

CHINA ACAD OF BUILDING RES +1

View PDF11 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, for a long time, since the curing of ultra-high-performance concrete needs to be cured by high-temperature steam, the application of in-situ pouring of ultra-high-performance concrete has been limited.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1- Embodiment 6

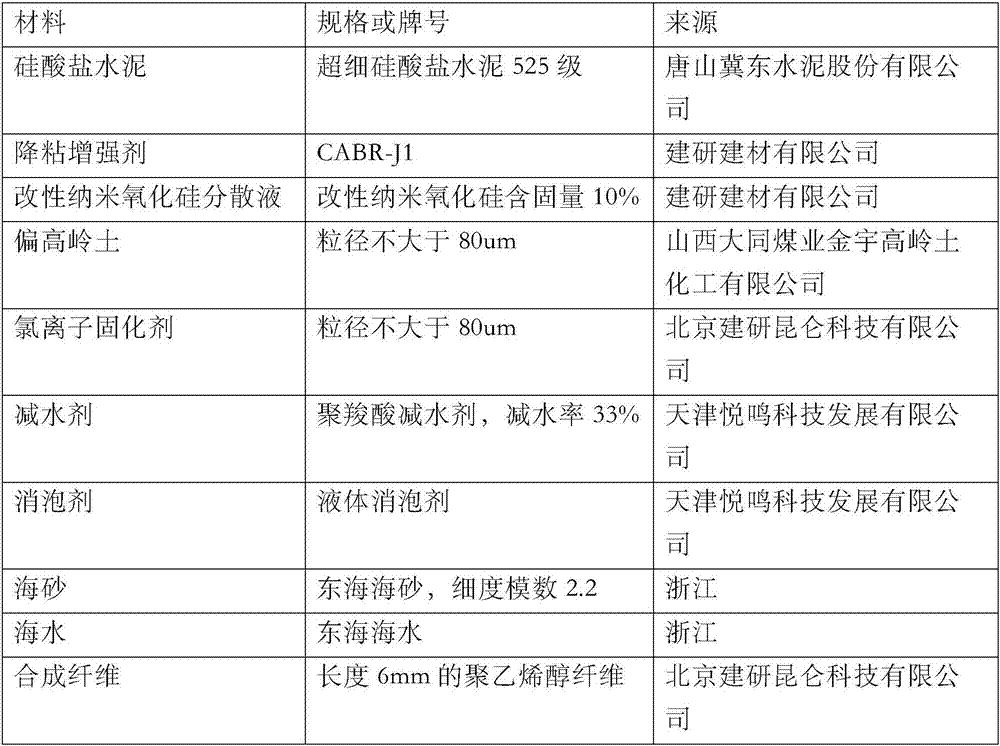

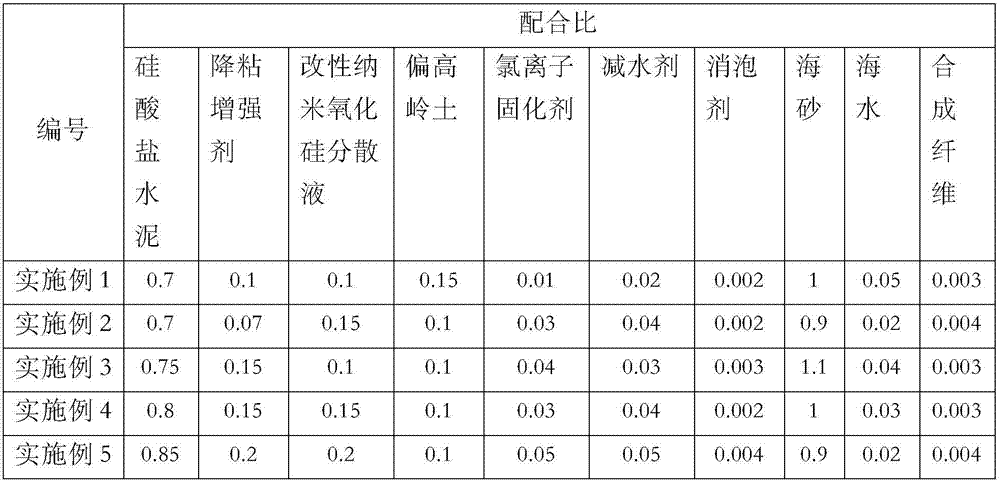

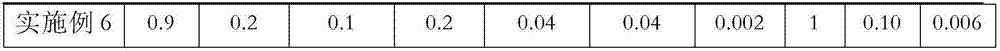

[0037] Embodiment 1-Example 6: sea sand ultra-high performance concrete. See Table 1 for raw materials and specifications, and Table 2 and Table 3 for material ratios and properties.

[0038] Table 1 Raw materials and specifications

[0039]

[0040] Table 2 Proportion of sea sand ultra-high performance concrete embodiment of the present invention

[0041]

[0042]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Login to View More

Abstract

The invention belongs to the technical field of a novel construction material and specifically relates to an ultrahigh performance sea sand concrete and a preparation method thereof. The ultrahigh performance sea sand concrete is prepared from cement, viscosity-reducing reinforcing agent, modified nanometer silicon dioxide dispersing solution, metakaolin, chloride ion curing agent, water reducingagent, de-foaming agent, sea sand, seawater and synthetic fiber at certain ratio. According to the invention, the viscosity-reducing reinforcing agent is adopted, so that the ultrahigh performance concrete still has better working property under the condition of lower water binder ratio; the modified nanometer silicon dioxide dispersing solution and the chloride ion curing agent are respectively adopted, so that the strength and durability of the ultrahigh performance concrete under normal temperature curing condition are greatly higher than those of the ultrahigh performance concrete at traditional silicon fume ratio; according to the invention, the sea sand and the seawater are used as some raw materials and are used for preparing the ultrahigh performance concrete, higher mechanical property and durability can be uniquely achieved in the manner of normal temperature moisturizing curing, the technical method is novel, the cost is lowered and the engineering can be practically popularized.

Description

technical field [0001] The invention belongs to the technical field of new building materials, and in particular relates to a sea sand ultra-high performance concrete and a preparation method thereof. Background technique [0002] Ultra-high performance concrete is characterized by ultra-high strength, toughness and durability, and has become a new system to achieve a great leap in the performance of cement-based materials. Ultra-high performance concrete originated in Denmark in the 1970s. Ultra-high-performance concrete is composed of graded quartz sand, finely ground quartz powder, cement, mineral admixtures, water reducers and other main components. During the setting and hardening process, it is cured by high-temperature steam to improve the microstructure of the finished product. [0003] Due to its ultra-high strength and other excellent performances, ultra-high performance concrete has received extensive attention from the international civil engineering community. ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C04B28/04

Inventor 周永祥王晶夏京亮王祖琦宋普涛冷发光倪博文周文

Owner CHINA ACAD OF BUILDING RES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com